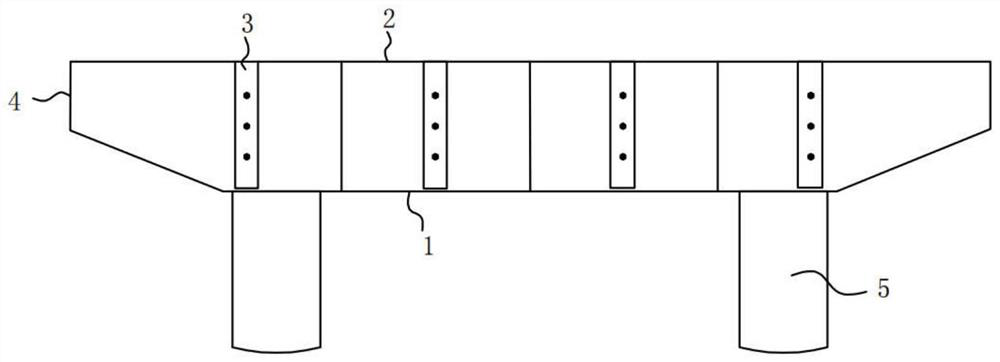

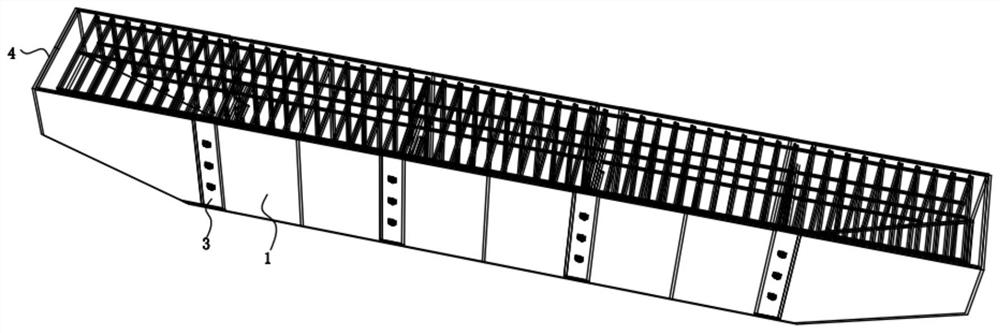

Cover beam of semi-prefabricated assembly type high-performance concrete formwork and construction method

A high-performance concrete and prefabricated technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve problems such as difficult installation and operation, and achieve the effect of simplifying the construction process, concise and reasonable components, and reducing the difficulty of transportation and hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

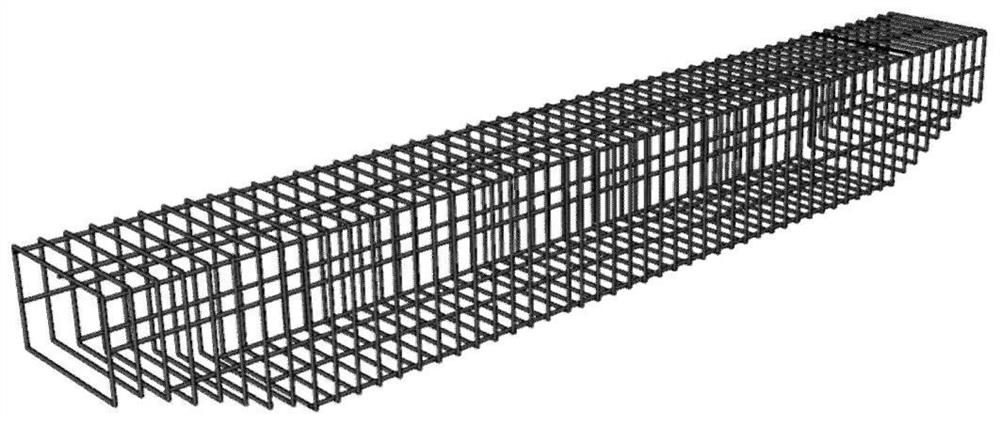

[0124] Please refer to Figure 11 , Figure 12 , Figure 13 and Figure 14 , based on the cover beam of the semi-prefabricated high-performance concrete formwork provided by the first embodiment of the present application, the second embodiment of the present application proposes another cover beam of the semi-prefabricated high-performance concrete formwork. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0125] Specifically, the difference between the cover beam of the semi-prefabricated high-performance concrete formwork provided by the second embodiment of the present application is that, in the cover beam of the semi-prefabricated high-performance concrete formwork, one end of the web 2 is provided with a A connector, the other end of the web 2 is provided with an assembly hole 10, the connector includes a front end 20 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com