A differential displacement sensor detection device and detection method

A displacement sensor and detection device technology, which is applied in the direction of measuring devices, electromechanical devices, and electrical devices, etc., can solve the problem of low detection accuracy and achieve the effect of improving accuracy and realizing detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

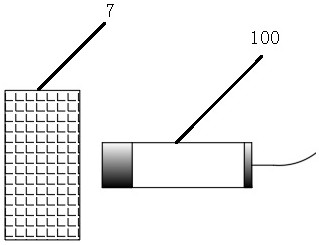

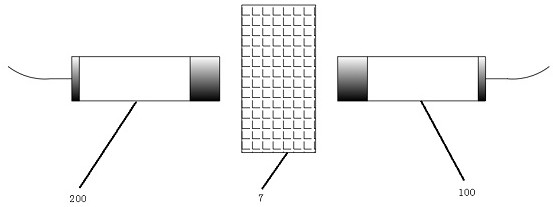

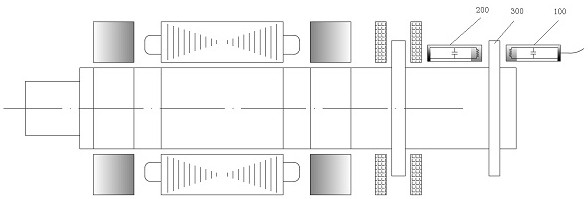

[0043] Please refer to Figure 4 to Figure 6 As shown, a differential displacement sensor detection device in this embodiment includes a workpiece to be tested 7, a displacement sensor assembly and a signal processing unit, wherein a rotor thrust plate is fixed on the workpiece to be tested 7 13. Left and right axial magnetic bearings (12, 14) are provided on both sides of the rotor thrust plate 13. The displacement sensor assembly includes a first sensor probe 1, a second sensor probe 4, and a signal processing unit connected to the first sensor probe and the second sensor probe; wherein, the first sensor probe 1 and the second sensor probe 4 are both It is fixedly arranged on the same side of the workpiece 7 under test, and the probes of the two are located on the same detection surface, and the signal processing unit is used for conditioning and analyzing the voltage signals output by the first sensor probe and the second sensor probe.

[0044] Specifically, a differential...

Embodiment 2

[0048] combine Figure 7 The schematic diagram of the principle framework of the signal processing unit shown, this embodiment is based on the first embodiment, as a specific implementation, the signal processing unit in this embodiment includes an excitation circuit, a coupling resistor, a multiplier and a low-pass filter. The excitation circuit generates a high-frequency signal and sends it to the parallel resonant circuit composed of the inductance coil and the capacitor through the coupling resistance Rs. The amplitude of the high-frequency signal of the probe coil caused by the change of the measured workpiece position is equivalent to modulating the measured workpiece position change to the excitation. On the signal, the multiplier multiplies the modulated signal and the excitation signal, and outputs a pair of signals with changed phases to the low-pass filter. After the amplitude-modulated signal passes through the low-pass filter, the high-frequency carrier signal is ...

Embodiment 3

[0055] like Figure 9 A differential displacement sensor detection method shown in this embodiment includes the differential displacement sensor detection device described in any one of the first embodiment and the second embodiment, and the detection method includes the following steps:

[0056] When the measured workpiece is shifted to the right, the voltage signal output by the first sensor probe gradually increases, and the voltage signal output by the second sensor probe gradually decreases, and the electromagnetic attraction force of the right axial magnetic bearing increases. , the electromagnetic suction force of the left axial magnetic bearing is reduced, so that the measured workpiece is adjusted to the left.

[0057] like Figure 10 A differential displacement sensor detection method shown in this embodiment includes the differential displacement sensor detection device described in any one of the first embodiment and the second embodiment, and the detection method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com