Oil storage tank area fire simulation experiment platform

A technology for simulation experiments and oil storage tank farms, which is applied in the field of fire simulation experiment platforms for oil storage tank farms, can solve problems such as difficulty in preventing fire extinguishing effects and lack of fire protection, and achieve fire accidents that are true, reliable, practical, and improve the level of fire protection technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

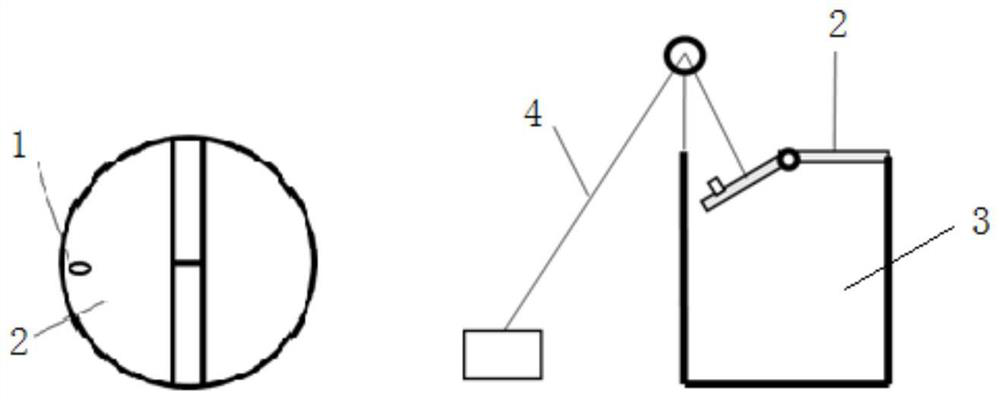

[0026] A fire simulation experiment platform in an oil storage tank area in this embodiment is used to simulate a fire situation in a fixed-roof oil storage tank. The schematic diagram of the simulation experiment platform is as follows: figure 1 As shown in the figure, it includes a dike, an oil storage tank 3 is arranged inside the dike, and the tank top of the oil storage tank 3 is composed of two semicircles of the same size, and the two semicircles are movably connected, wherein the first semicircle is fixed on the oil storage tank 3 At the top, the second semicircle rotates around the connecting shaft of the two semicircles. A through hole is set on the second semicircle. The through hole is used to install the first pressure relief valve 1 and the pressure gauge. The inner bottom of the oil storage tank 3 is provided with a heating rod. An ignition electrode is arranged on the inner wall of the oil tank 3 .

[0027] The oil storage tank 3 in this embodiment is used to ...

Embodiment 2

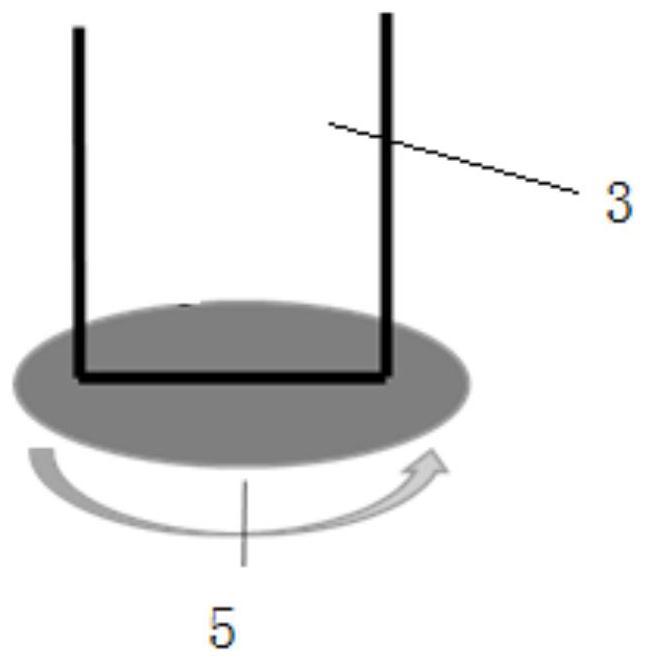

[0032] The fire simulation experiment platform of the oil storage tank area in this embodiment is used to simulate the fire cyclone of the oil storage tank. The simulation experiment platform in this embodiment, the structural device diagram is as follows figure 2 As shown, a rotating device 5 is installed below the oil storage tank 3, the oil storage tank 3 is set to be open, an ignition electrode is arranged on the inner wall of the oil storage tank 3, and the rotating device 5 is connected to the motor.

[0033] The rotating device 5 is a rotatable circular turntable. The rotation of the circular turntable is controlled by the motor, and then the oil storage tank 3 is driven to rotate. At the beginning of the experiment, the fuel is ignited. After the combustion is stable, the rotating device 5 is started to observe the experimental phenomenon.

[0034] After a fire occurs in the 3rd area of the oil storage tank, it is easy to cause multi-tank combustion, the number of f...

Embodiment 3

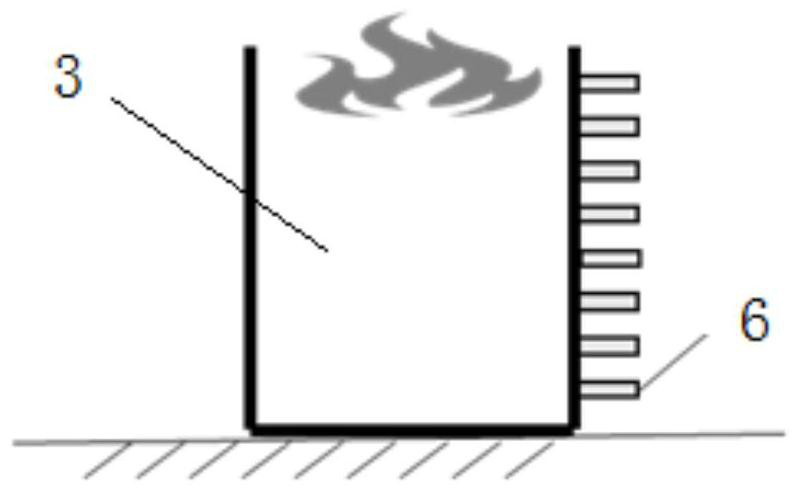

[0036] The fire simulation experiment platform in an oil storage tank area described in this embodiment is used to simulate a flowing combustion fire in an oil storage tank. The simulation experiment platform in this embodiment has a schematic structural diagram such as image 3 shown. In this embodiment, the side wall of the oil storage tank 3 has a series of holes along the vertical direction, and an electric valve pipeline 6 is arranged outside each hole. The highest point of the oil pool is below the ground.

[0037] In this embodiment, a row of holes is opened along the vertical direction on one side of the oil storage tank 3, the number of which is 8, and the pipes are extended outward.

[0038] Before the simulation experiment, according to the fires that simulate different liquid level conditions, oil is injected into the oil storage tank 3 to the corresponding liquid level. During the experiment, a small oil pool was ignited, and a single or multiple electric valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com