Fracture traction reduction device

A traction reset and traction component technology, applied in the direction of fixator, external fixator, etc., can solve the problems of unable to achieve any angle and position adjustment movement, poor flexibility of multi-angle adjustment, unable to stabilize traction reset, etc., and achieve stable and precise traction force. The effect of reducing the inaccuracy of docking and eliminating the unstable factors of rod shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

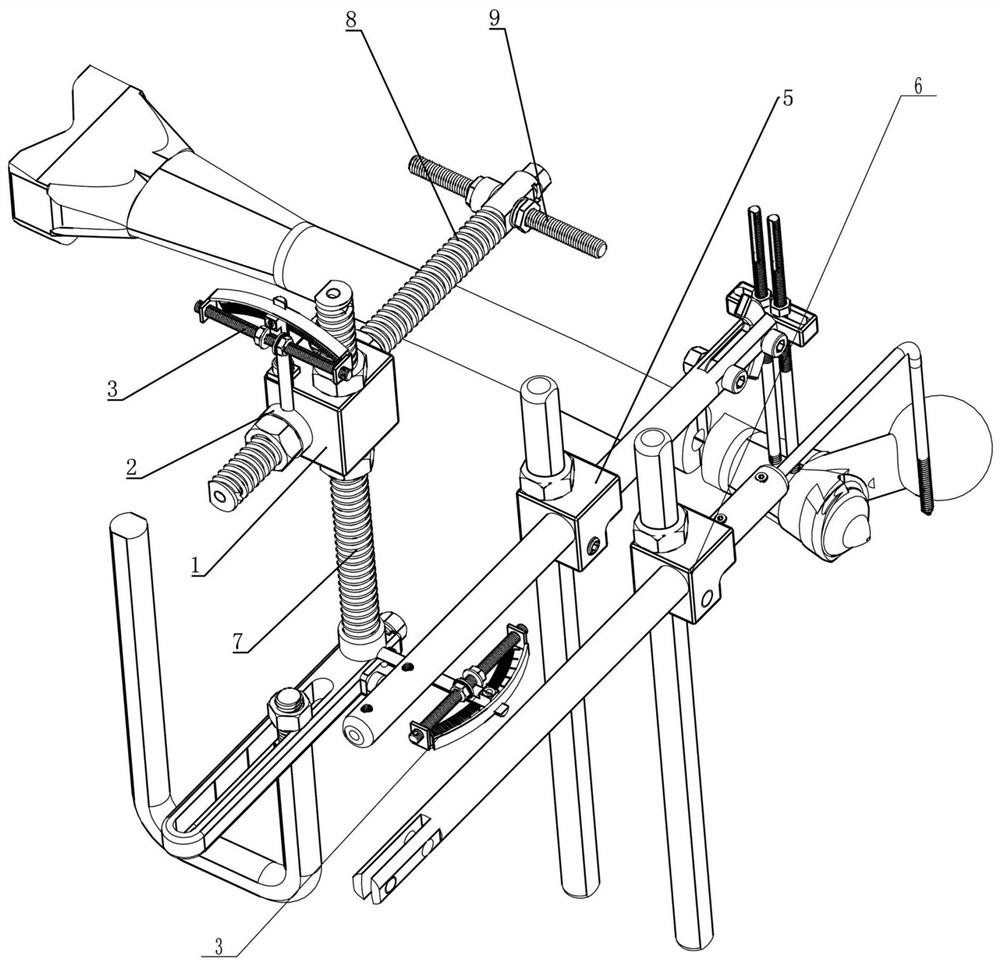

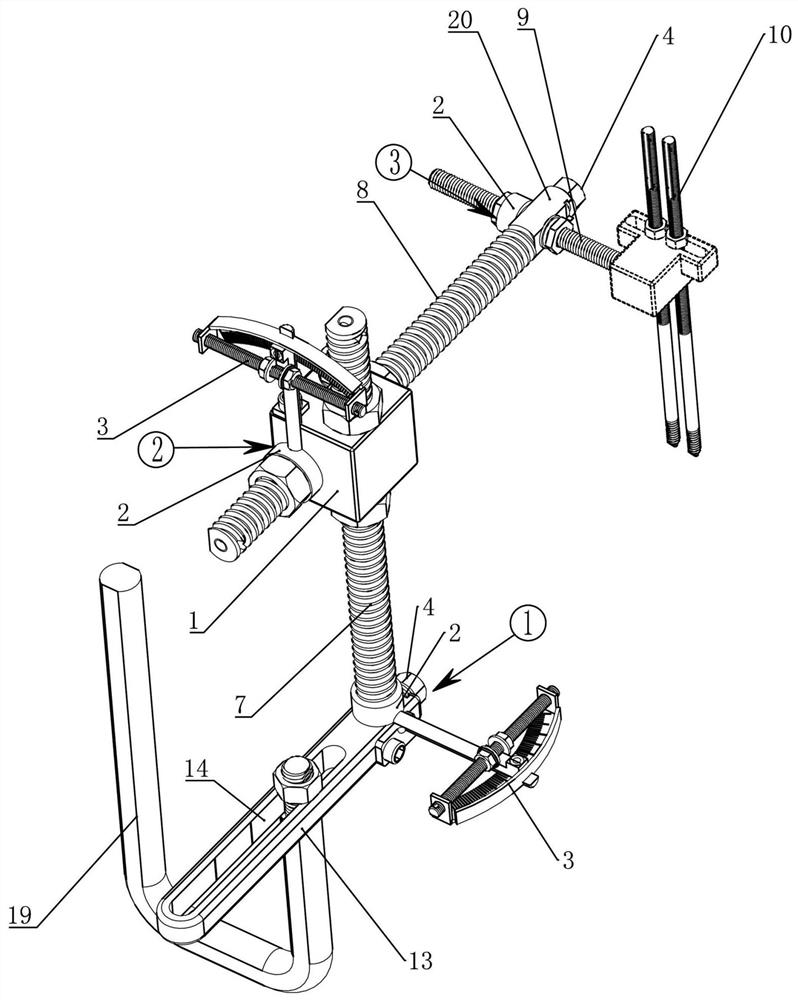

[0047] Example 1: A fracture traction reduction device, the device adopts an adjustable traction component such as figure 2 shown, using mating traction assemblies such as image 3 shown.

[0048] figure 2 The adjustment and traction assembly in the device mainly includes a threaded column 7, a threaded transverse rod 8 and a threaded longitudinal rod 9, a first node, a second node and a third node.

[0049] The upright column 7 is connected with the outer support through a first node, the upright column is perpendicular to the cross bar and connected by a second node, and the end of the cross bar is perpendicular to the longitudinal bar and connected by a third node.

[0050] The structure of the outer bracket is not limited, and any existing outer bracket for fixing the rod can be used. figure 2 As shown, a bar-shaped hole 14 is provided on the outer adjusting frame 13, and one end of a U-shaped outer fixing frame 19 is inserted and fixed in the proper position of the ...

Embodiment 2

[0065] Embodiment 2: On the basis of Embodiment 1, the vertical movement adjustment mechanism in this embodiment is provided with a vertical through hole vertically through the end point of the node 1 (outer adjustment frame 13 ), and the vertical hole is matched with a sleeve. There is a rotating sleeve 21 with an angle adjustment mechanism. The rotating sleeve 21 is matched with a threaded column 7. An anti-rotation key or track or special-shaped section is arranged between the rotating sleeve 21 and the threaded column 7. For the lock nut 18 on the column, loosen one lock nut and screw the other lock nut to drive the node 1 to reciprocate vertically relative to the column.

[0066] The lateral movement adjustment mechanism in this embodiment is provided with a transverse perforation on the main body of the node 2 or node 3 along the lateral direction. 8. An anti-rotation key or track or special-shaped section is set between the rotating sleeve 21 and the threaded cross bar ...

Embodiment 3

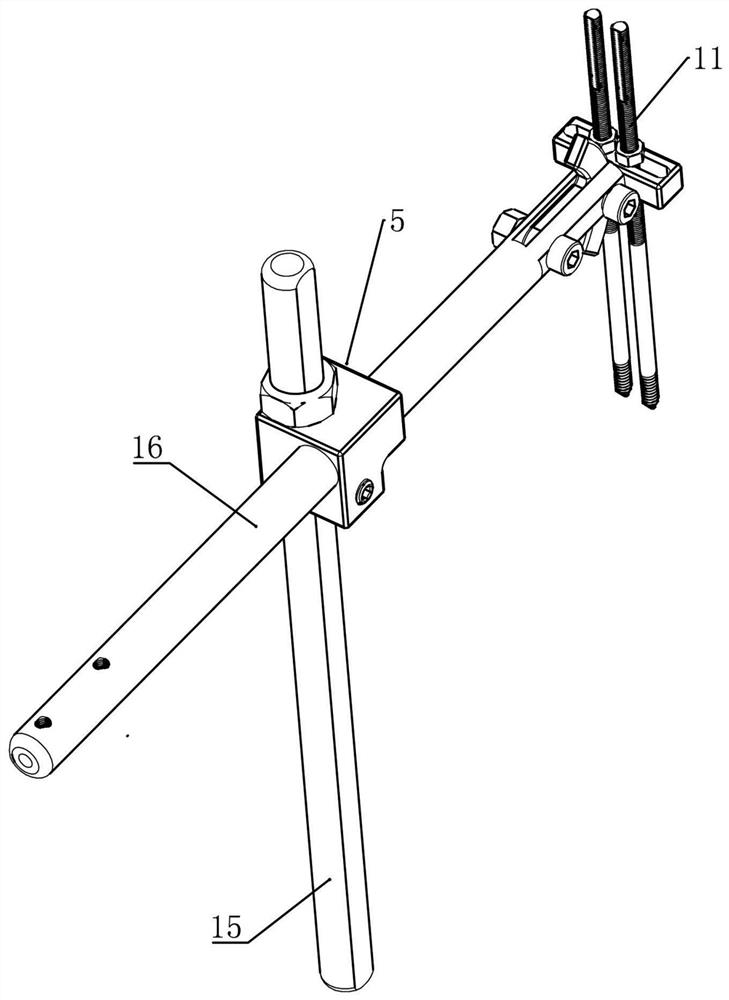

[0068] Embodiment 3: On the basis of Embodiment 1, the above various adjustment mechanisms are respectively replaced with the following Figure 10 Angle adjustment mechanism shown. Figure 10 It can be seen that a radial connecting plate 201 is extended and fixed on the outer side of the rotating sleeve 21, and an arc-shaped hole 202 is provided on the radial connecting plate 201. The locking wire 203, after loosening the locking wire 203, can ensure that the rotating sleeve 21 only rotates in the through hole of the node, and can lock the rotating sleeve 21 after tightening the locking wire 203.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com