Blade matrix type batch modification device and method for activated carbon fibers

A technology of activated carbon fiber and activated carbon fiber, which is applied in the field of activated carbon fiber blade matrix batch modification device, which can solve the problems of incapable of large-scale application process production and inability to realize batch modification of activated carbon fiber, and achieve high economical practicability , saving modification time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

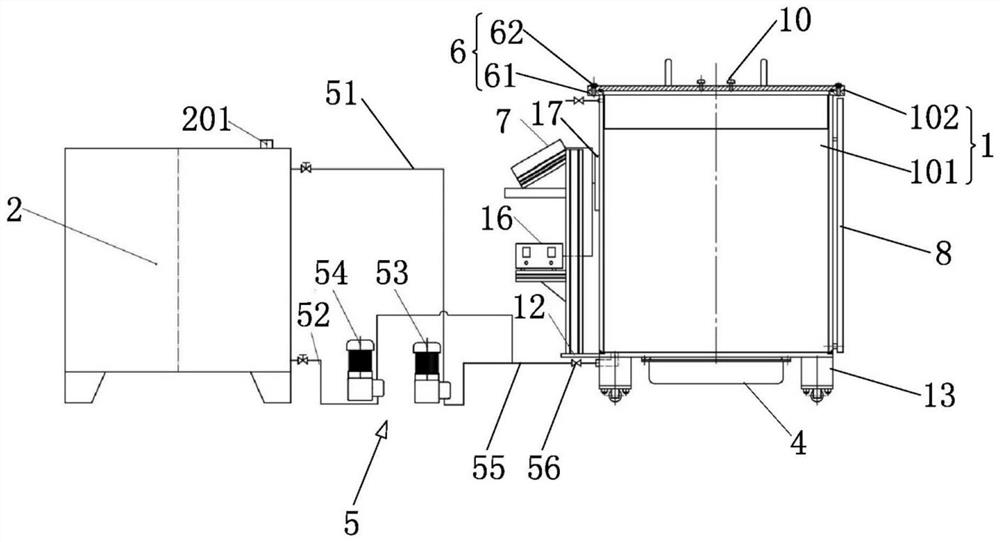

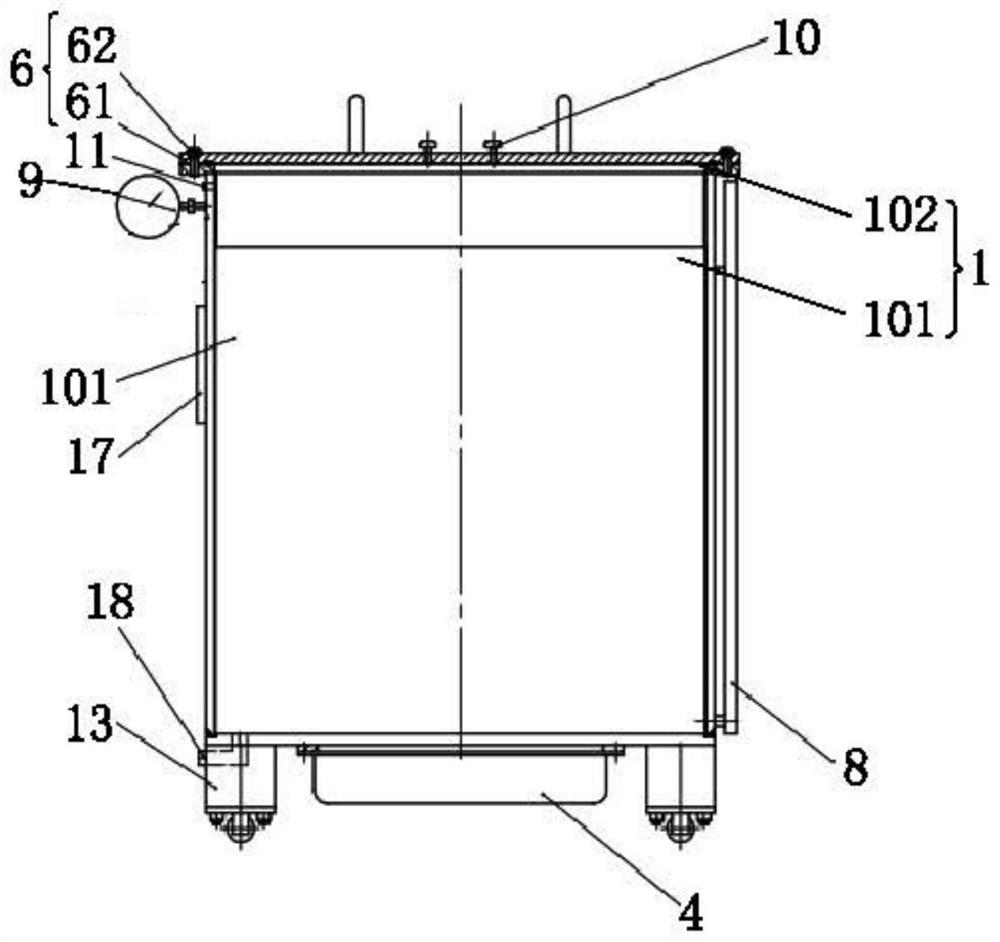

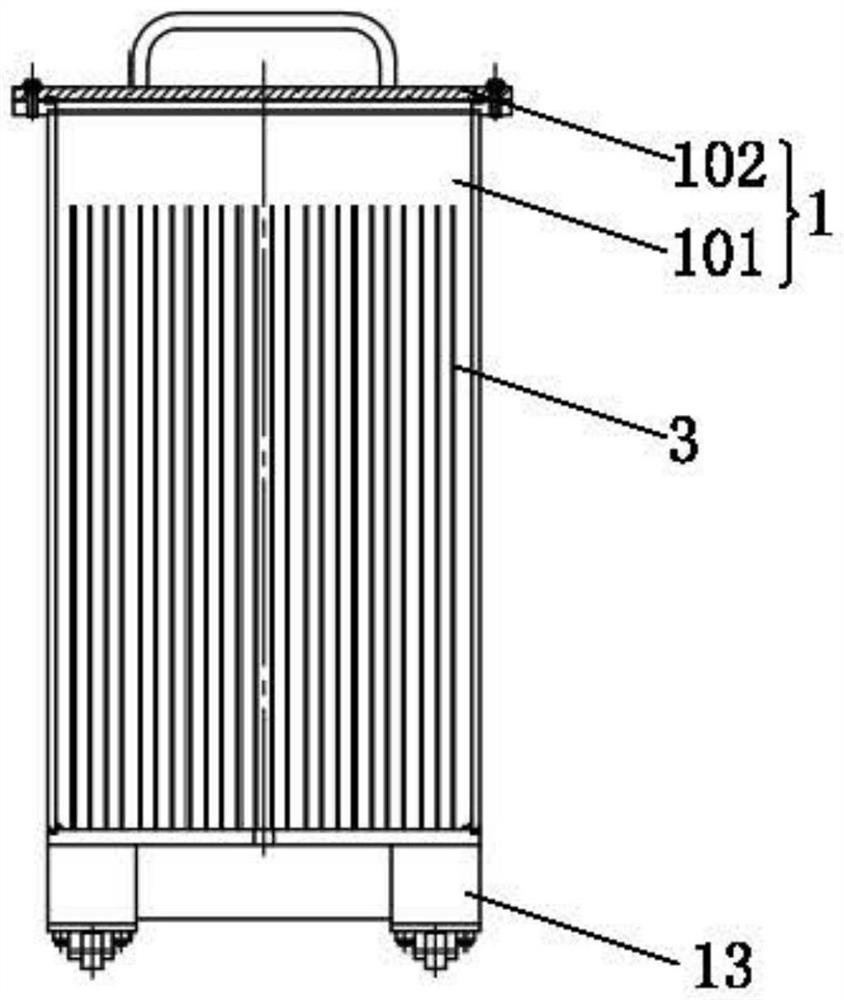

[0036] Depend on Figure 1-Figure 5 As shown, an activated carbon fiber blade matrix type batch modification device includes a modification reaction device and a liquid storage device 2 for storing and preparing a modifier solution. The modification reaction device includes a modification kettle 1, which is the described The heating device 4 for heating the modification kettle 1 and the safety valve 10 for controlling the pressure of the modification kettle 1. The modification kettle 1 includes a kettle body 101 and a kettle cover 102 that are used in cooperation with each other. The kettle lids 102 are detachably connected; the inner cavity of the kettle body 101 is provided with a plurality of vertically arranged support nets 31, and every two pieces of the support nets 31 form a space for accommodating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com