Temperature-sensitive color-changing agent as well as preparation method and application thereof

A temperature-sensitive color changing and temperature-sensitive color changing powder technology is applied in the field of temperature-sensitive color changing agent and its preparation, which can solve the problems of not fundamentally improving the quality of the microcapsule shell, and achieve mechanical extrusion resistance, good effect and chemical resistance. The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

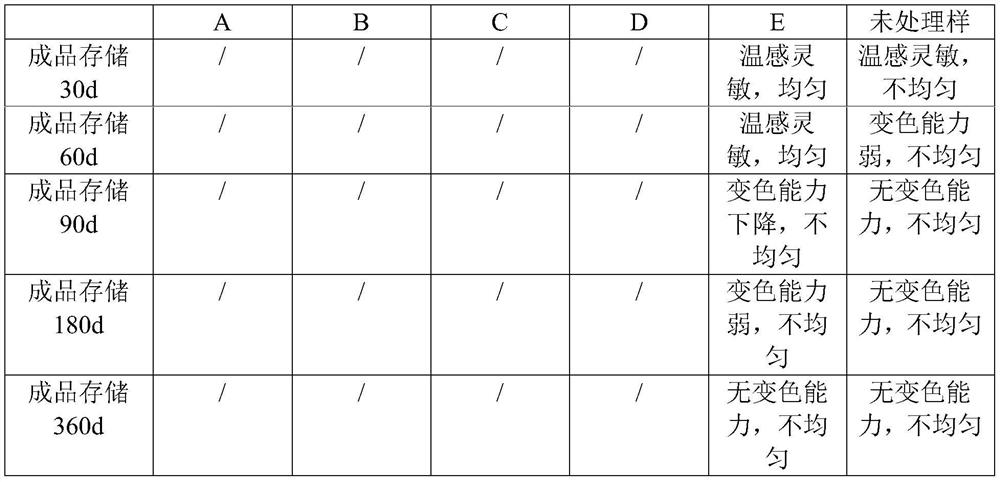

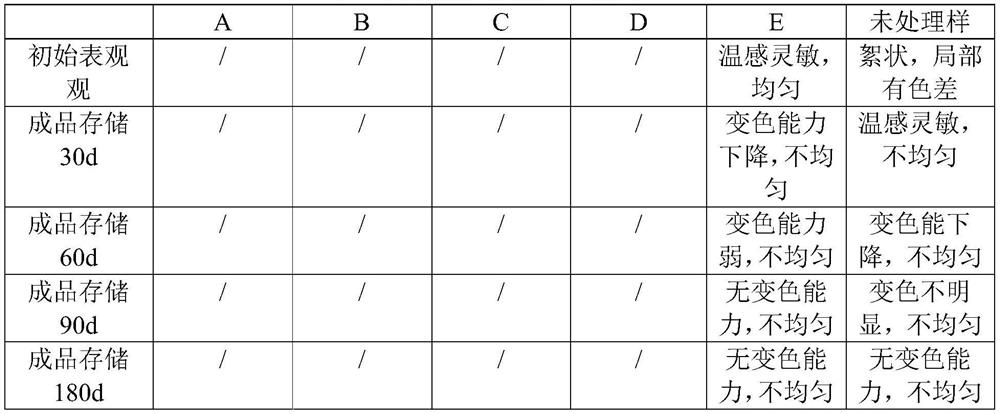

Examples

Embodiment 1

[0067] Add 10kg of green thermochromic microcapsules with an average particle size of 1μm at 75°C and a shell thickness of 200nm into a double-cone mixer, extract the air into a vacuum state, and add 500g of hexamethyldisilazane to 100°C using a metering pump. 10g / min was added into the kettle at a constant speed through the atomizer under the running state of the mixer, fully contacted and reacted, stirred for 1 h after all added, and then distilled under vacuum and reduced pressure to remove low molecular weight for 0.5 h, and cooled to room temperature to obtain sample A spare.

Embodiment 2

[0069] Add 10kg of green thermochromic microcapsules with an average particle size of 5μm at 75°C and a shell thickness of 250nm into a double-cone mixer, extract the air into a vacuum state, and add 1500g hexamethyldisilazane to 50g using a metering pump after adding to 100°C. When the mixer is running and atomized by the atomizer at a constant speed, it is added into the kettle at a constant speed, and the reaction is fully contacted. After all the addition is added, it is stirred for 2 hours, and then the low molecules are distilled off under vacuum and reduced pressure for 0.5 hours, and cooled to room temperature to obtain sample B for use. .

Embodiment 3

[0071] Add 10kg of green thermochromic microcapsules with an average particle size of 5μm at 75°C and a shell thickness of 300nm into a double-cone mixer, extract the air into a vacuum state, and add 500g of dimethyldichlorosilane to 10g / m using a metering pump. min Under the running state of the stirrer and atomized by the atomizer, it was added to the kettle at a constant speed, and the reaction was fully contacted. After all the additions were added, the mixture was stirred for 1 h, and then the low molecules were distilled off under vacuum and reduced pressure for 0.5 h, and then cooled to room temperature to obtain sample C for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com