Underground vehicle base foundation pit construction method

A vehicle base and construction method technology, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of inability to effectively provide lateral stiffness and inability to transmit lateral earth pressure in adjacent foundation pits, so as to facilitate the waterproofing of side walls , control the surrounding surface settlement, improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

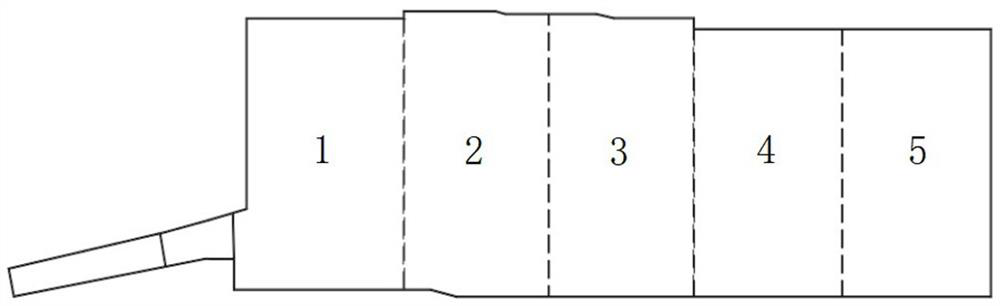

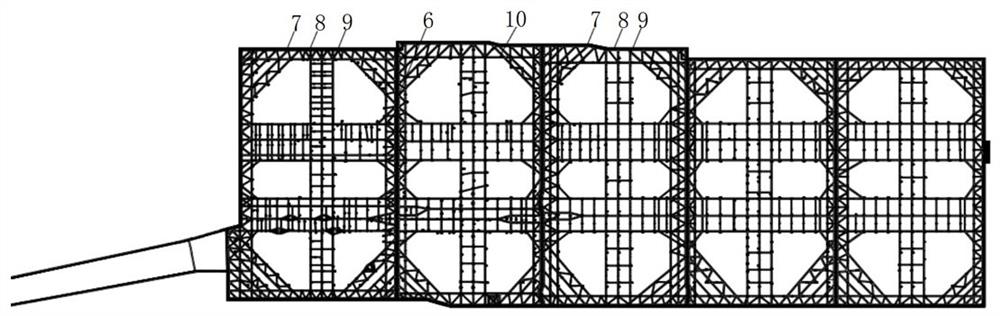

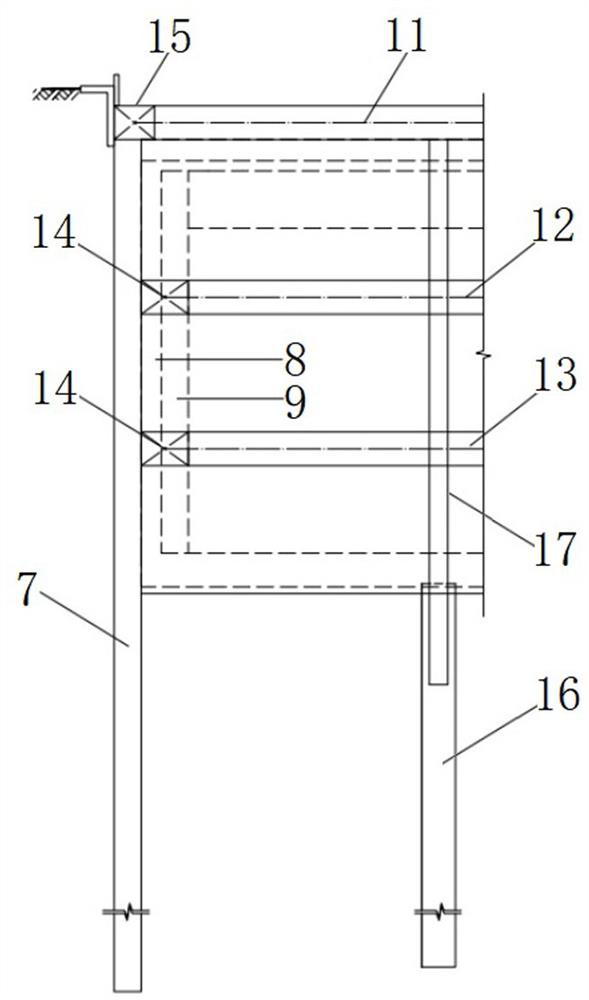

[0033] Example: The construction method for the foundation pit of the underground vehicle base in this example is used to figure 1 The construction of the foundation pit shown, which meets the needs of the ultra-large scale and ultra-high headroom of the underground vehicle base.

[0034] combine Figure 1 to Figure 4 As shown, the construction method of this embodiment specifically includes the following steps:

[0035] 1) First, the foundation pit is divided into the first sub-pit 1, the second sub-pit 2, the third sub-pit 3, the fourth sub-pit 4, and the fifth sub-pit 5 along the long side of its longer side. The foundation pit groups are adjacent to each other in turn. The foundation pit group is constructed in stages. The division of the staged construction is to divide each sub-pit into a first-stage foundation pit and a second-stage foundation pit in a spaced manner. In this embodiment, the first sub-pit 1 and the third sub-pit 3 are used. And the fifth sub-pit 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com