Drilling device based on positive and negative stiffness vibration reduction technology

A positive and negative stiffness, drilling device technology, applied in the direction of vibration suppression adjustment, spring/shock absorber, non-rotational vibration suppression, etc., can solve the problems of uneven force on negative stiffness structures, poor reusability, etc., to achieve limited support Effects of seat shift, reduced structural response, and reduced stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

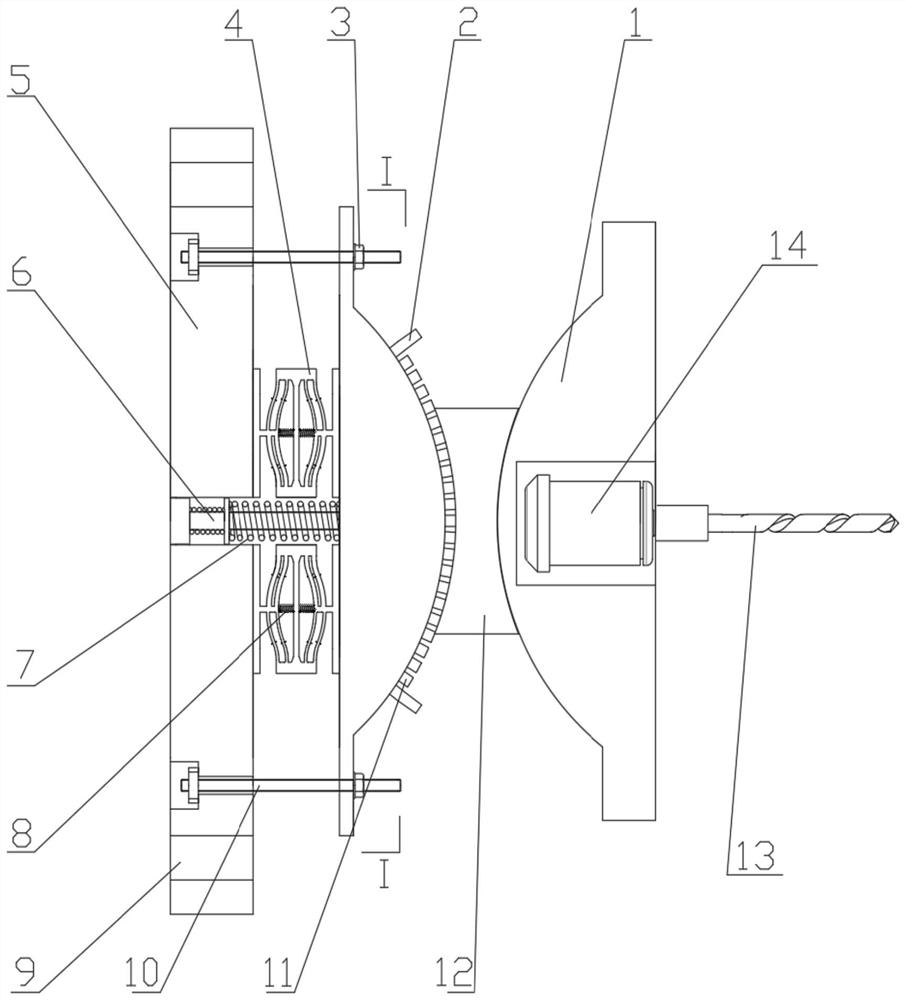

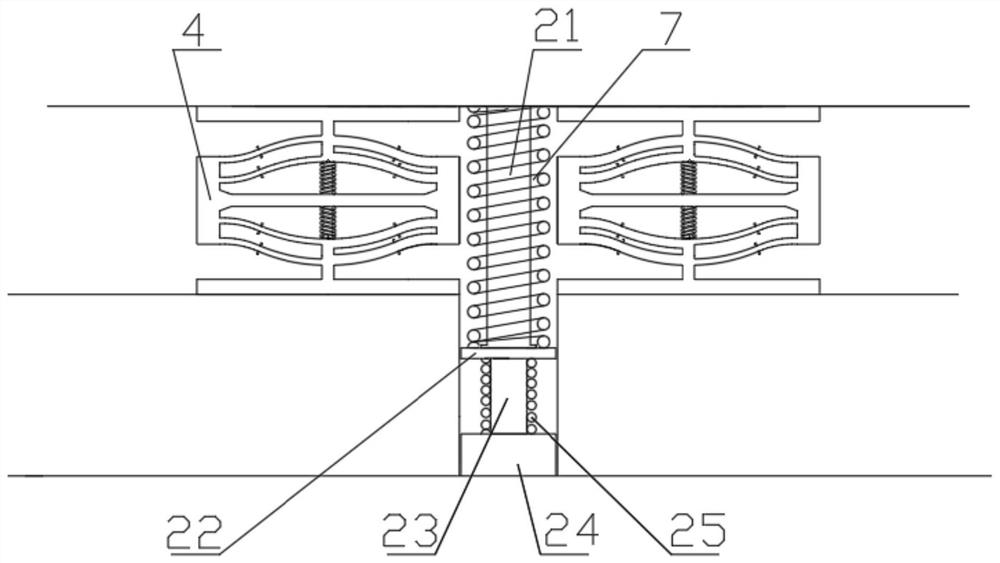

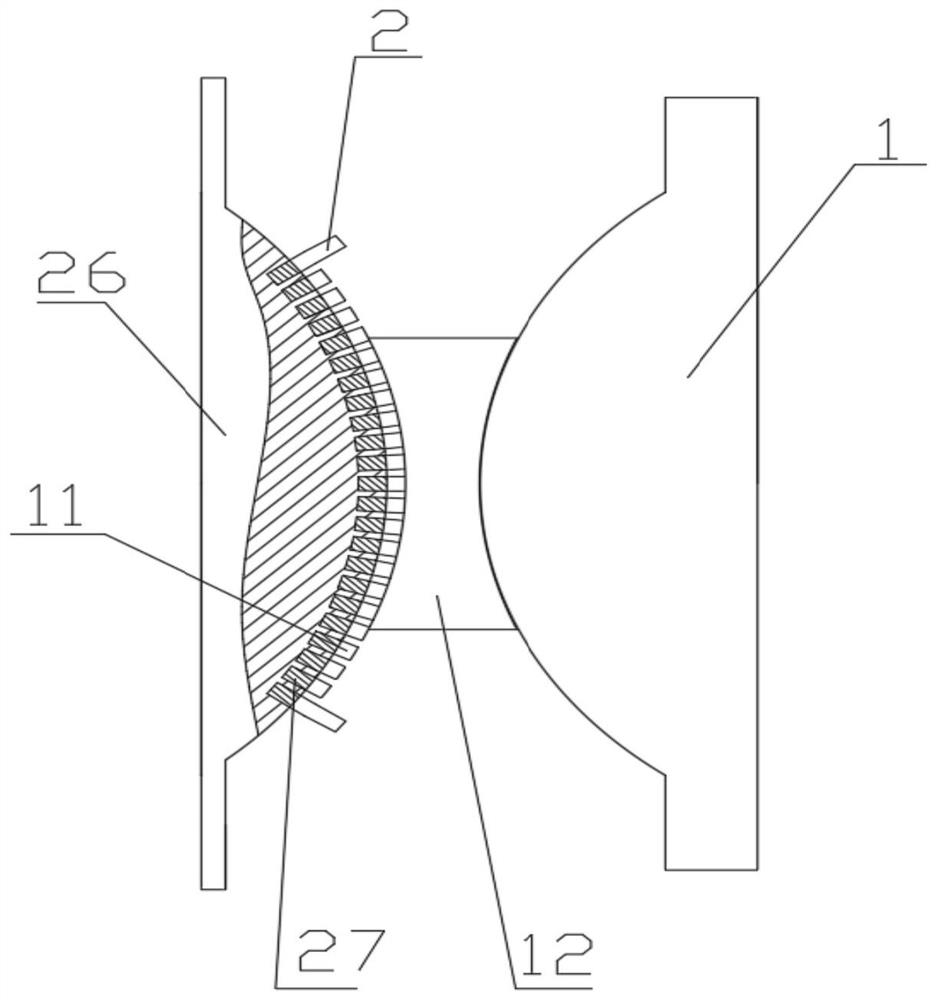

[0044] A drilling device based on positive and negative stiffness vibration reduction technology, such as Figure 1-3 As shown, it includes a positive and negative stiffness device for providing lateral vibration damping, a vibration isolation support for providing longitudinal negative stiffness effect, and a drilling actuator at the end of the manipulator; the positive and negative stiffness structure for lateral vibration damping and longitudinal negative stiffness are provided. The effective vibration isolation supports are connected in parallel as a vibration damping device, which is used to provide lateral and longitudinal buffer force to achieve the purpose of vibration damping and improve the accuracy of drilling. The positive and negative stiffness devices for lateral vibration reduction include a "cross"-shaped three-dimensional positive and negative stiffness honeycomb structure 4 , a variable stiffness spring device 6 , a limit rod 10 and a flange 5 . The vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com