Chip mounting device

A chip mounting, No. 1 technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as solder joints not corresponding, affecting chip mounting accuracy, etc., to reduce the length of the route, facilitate welding operations, and shorten the distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

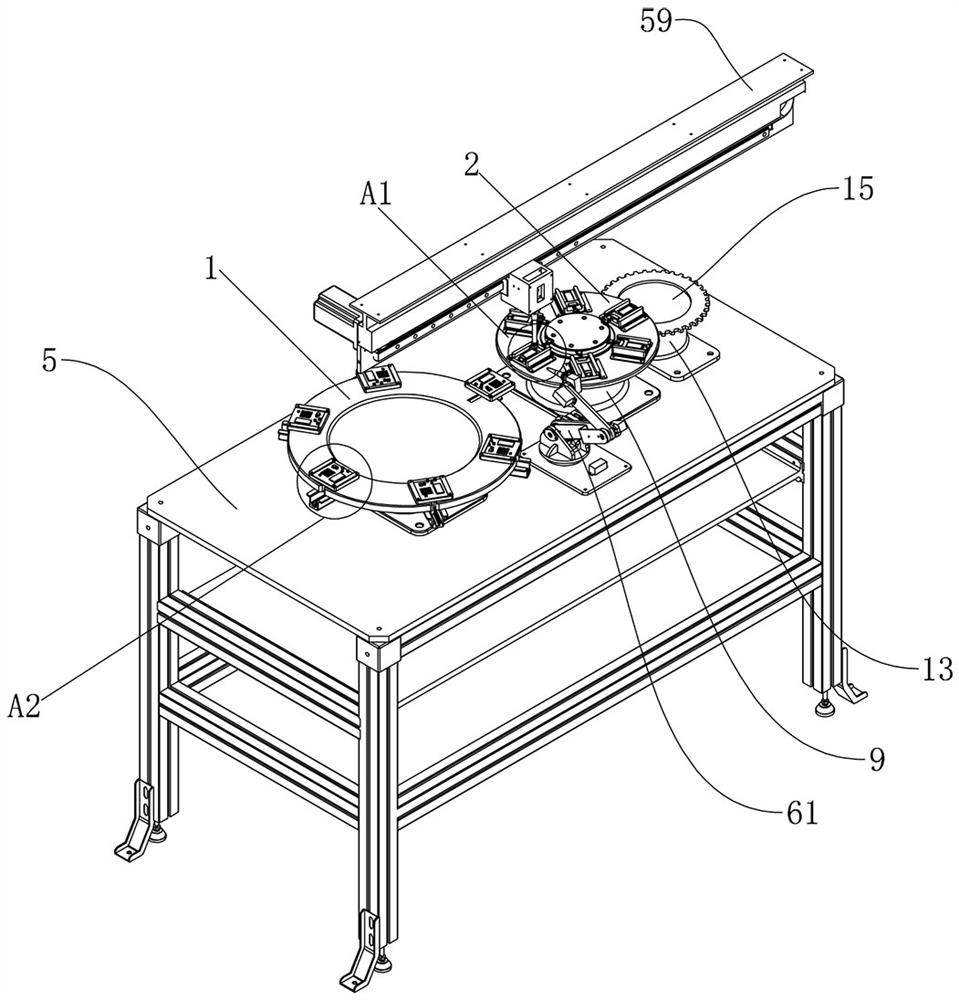

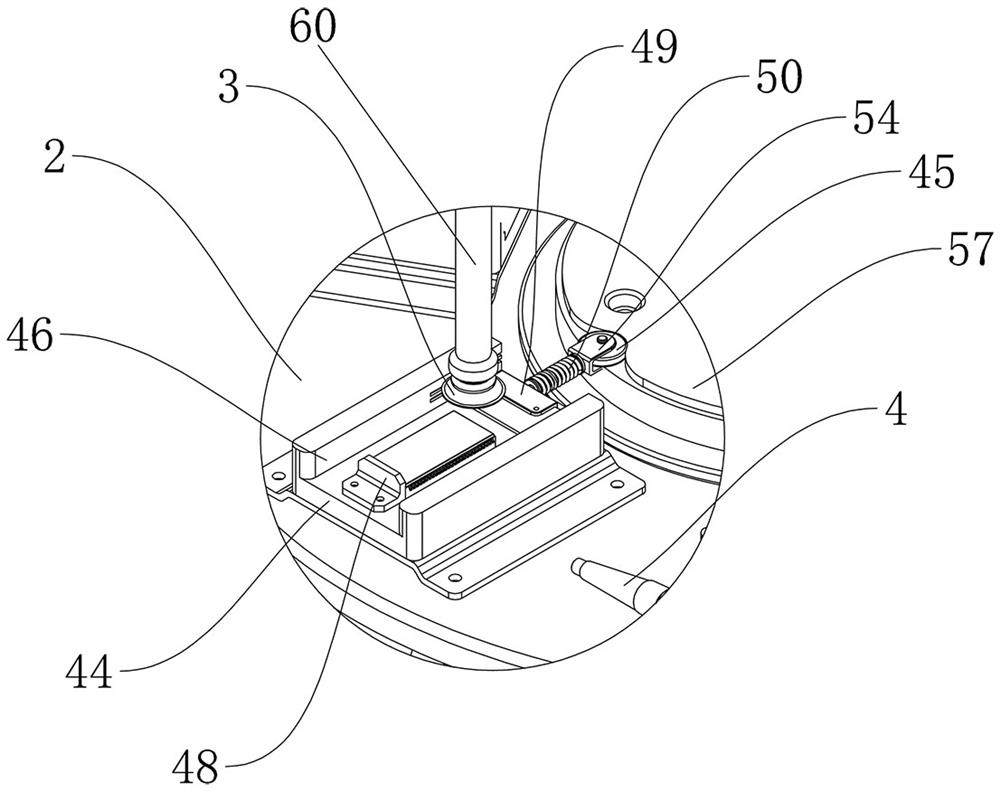

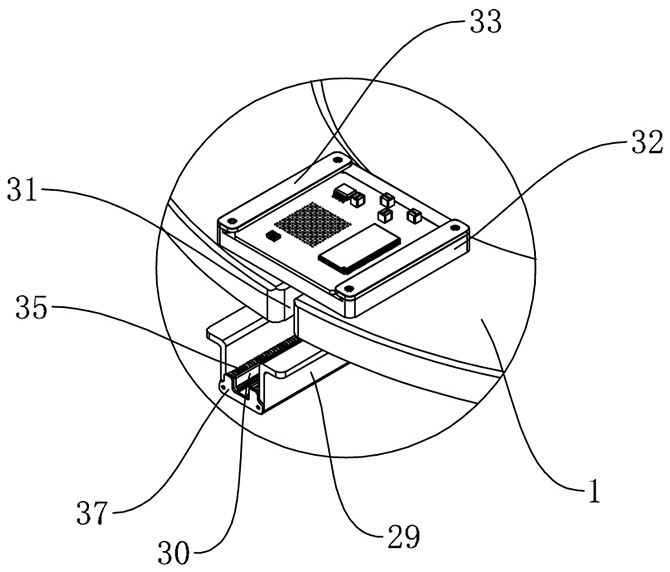

[0038] refer to Figure 1 to Figure 23 The shown chip mounting device includes a horizontal transfer assembly, a soldering assembly and a double turntable assembly, the double turntable assembly includes two No. Tray 2, the No. 1 carrier tray 1 and No. 2 carrier tray 2 are distributed at intervals along the horizontal direction and the centers of the two are on the same horizontal line, and the No. 1 carrier tray 1 is provided with several for fixing the substrate and can follow the No. 1 tray The No. 1 clamp that the carrier plate 1 rotates together, several of the No. 1 clamps are evenly distributed along the circumferential direction of the No. 1 carrier plate 1, and the angle between each pair of the adjacent No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com