Quick-frozen convenient alkaline water noodles and production method thereof

A production method and an alkali-convenient technology, which are applied to quick-freezing and convenient alkaline water surface and the production field thereof, can solve the problems of easy-to-adhesion of the alkaline-water surface, difficulty in long-term freezing and storage, etc., and achieves difficult to adhere to the agglomerate, strong water retention, and good viscosity. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

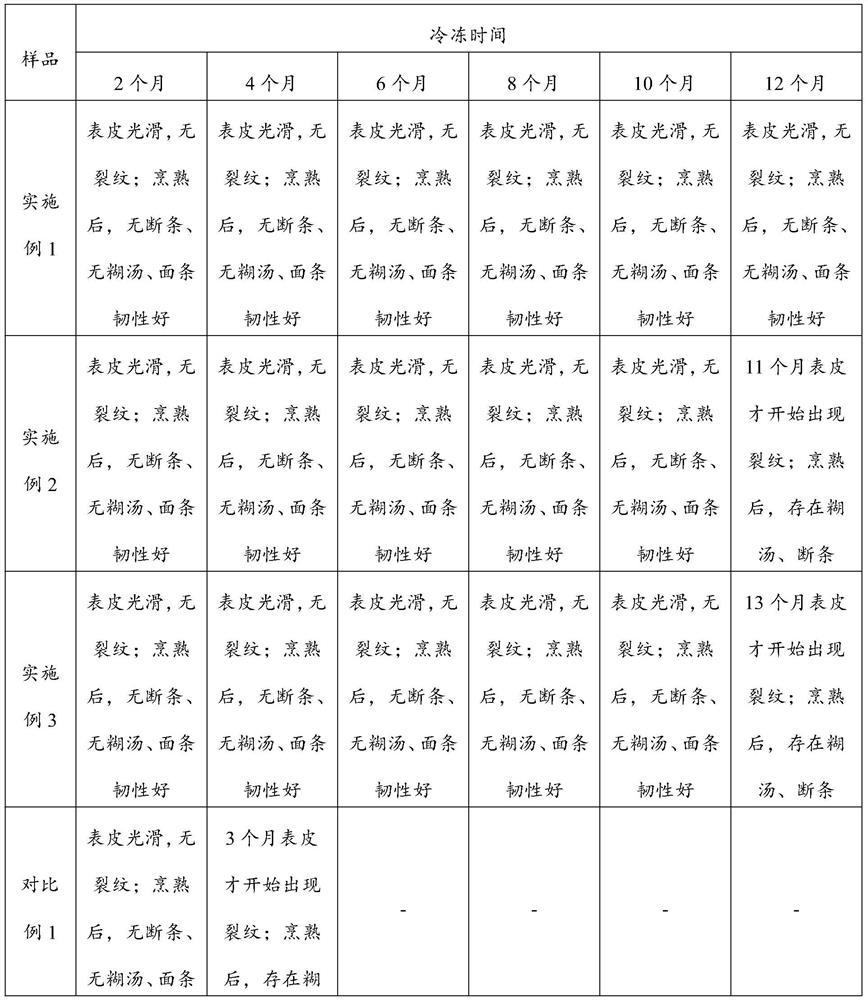

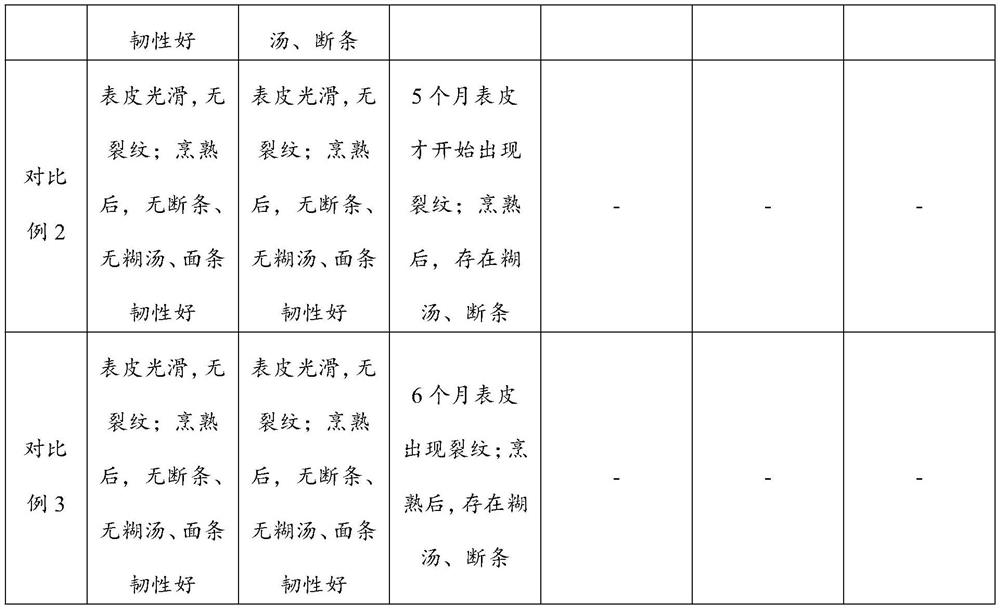

Examples

Embodiment 1

[0068] A quick-frozen convenient alkaline water surface is produced by the following production method:

[0069] The raw materials were prepared according to the following formula: 60 parts of flour, 0.1 part of salt, 0.1 part of potassium carbonate, 10 parts of acetate starch, 5 parts of hydroxypropyl distarch phosphate, and 33 parts of water, in parts by mass. Wherein, the substitution degree of acetate starch is 0.03, and the substitution degree of hydroxypropyl distarch phosphate is 0.7.

[0070] Mixing: Put the raw materials into the dough mixer and mix evenly to form a granular mixture.

[0071] Proofing: put the mixture on the proofing belt in the proofing box to proof; wherein, the proofing temperature is 23°C, and the proofing time is 30min.

[0072] Pressing and producing silk: The proofed mixture is sent to the pressing machine and repeatedly extruded into dough strips. The dough strips are rolled by pressing rollers to make noodles; the thickness of the dough stri...

Embodiment 2

[0078] A quick-frozen convenient alkaline water surface is produced by the following production method:

[0079] The raw materials were prepared according to the following formula: 75 parts of flour, 0.6 part of salt, 8 parts of potassium carbonate, 15 parts of acetate starch, 10 parts of hydroxypropyl distarch phosphate, and 38 parts of water. Wherein, the substitution degree of acetate starch is 0.09, and the substitution degree of hydroxypropyl distarch phosphate is 0.9.

[0080] Mixing: Put the raw materials into the dough mixer and mix evenly to form a granular mixture.

[0081] Proofing: Put the mixture on the proofing belt in the proofing box to proof; wherein, the proofing temperature is 28°C, and the proofing time is 50min.

[0082] Pressing and producing silk: The proofed mixture is sent to the pressing machine and repeatedly extruded into dough strips. The dough strips are rolled by pressing rollers to make noodles; the thickness of the dough strips is about 1.5mm....

Embodiment 3

[0088] A quick-frozen convenient alkaline water surface is produced by the following production method:

[0089] The raw materials were prepared according to the following formula: 70 parts of flour, 0.4 part of salt, 5 parts of potassium carbonate, 12 parts of acetate starch, 7 parts of hydroxypropyl distarch phosphate, and 35 parts of water. Among them, the substitution degree of acetate starch is 0.07, and the substitution degree of hydroxypropyl distarch phosphate is 0.8.

[0090] Mixing: Put the raw materials into the dough mixer and mix evenly to form a granular mixture.

[0091] Proofing: put the mixture on the proofing belt in the proofing box to proof; wherein, the proofing temperature is 25°C, and the proofing time is 35min.

[0092] Pressing and producing silk: The proofed mixture is sent to the pressing machine and repeatedly extruded into dough strips. The dough strips are rolled by pressing rollers to make noodles; the thickness of the dough strips is about 1.9m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com