Electrochemical nanometer pressure cavity

An electrochemical and nanotechnology, applied in chemical instruments and methods, chemical/physical processes, circuits, etc., can solve the problem of high experimental cost, achieve simple preparation process, realize in-situ continuous pressurization-decompression, and accurate pressure controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

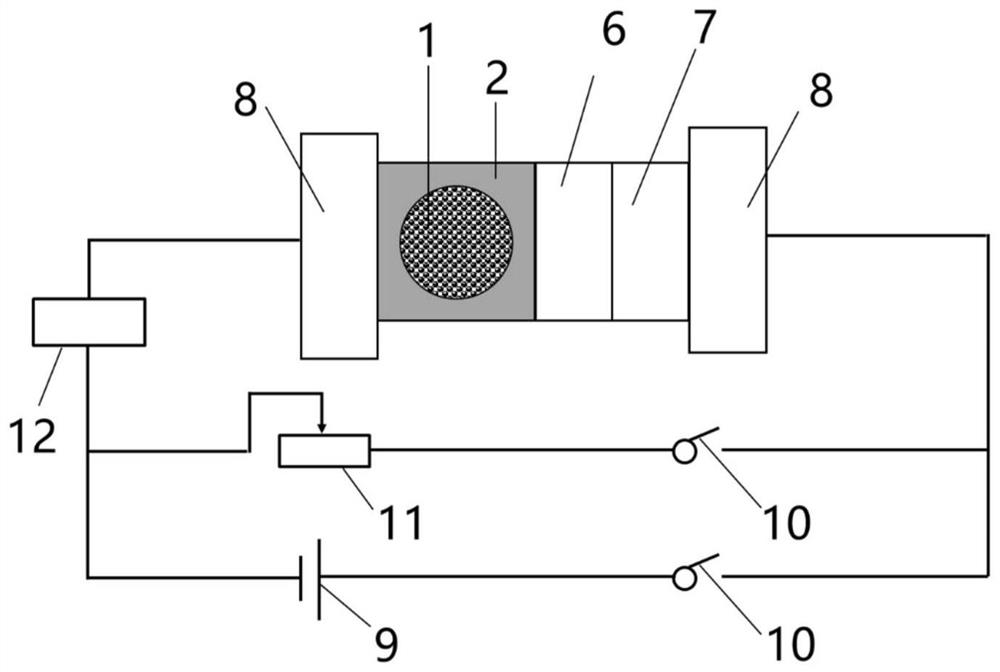

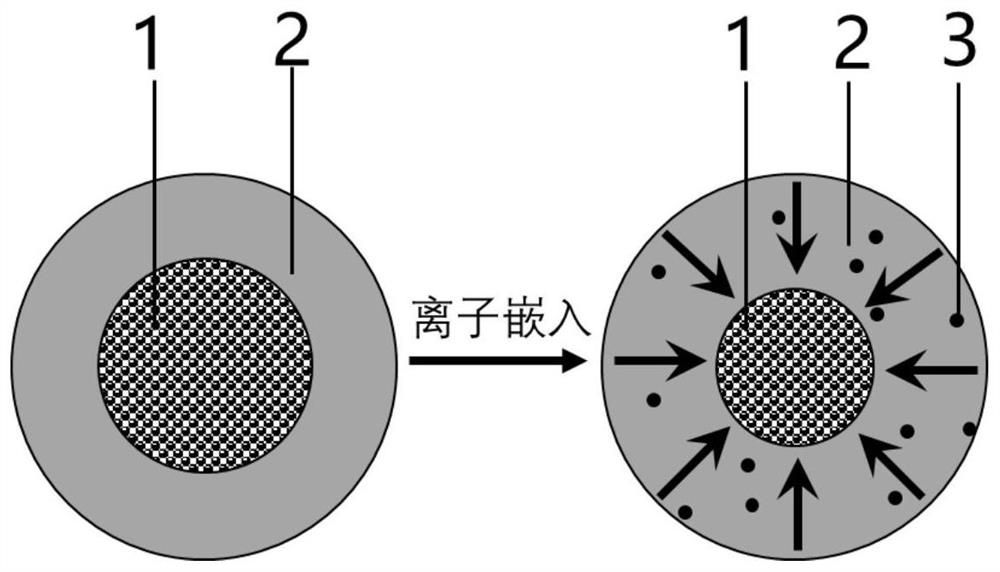

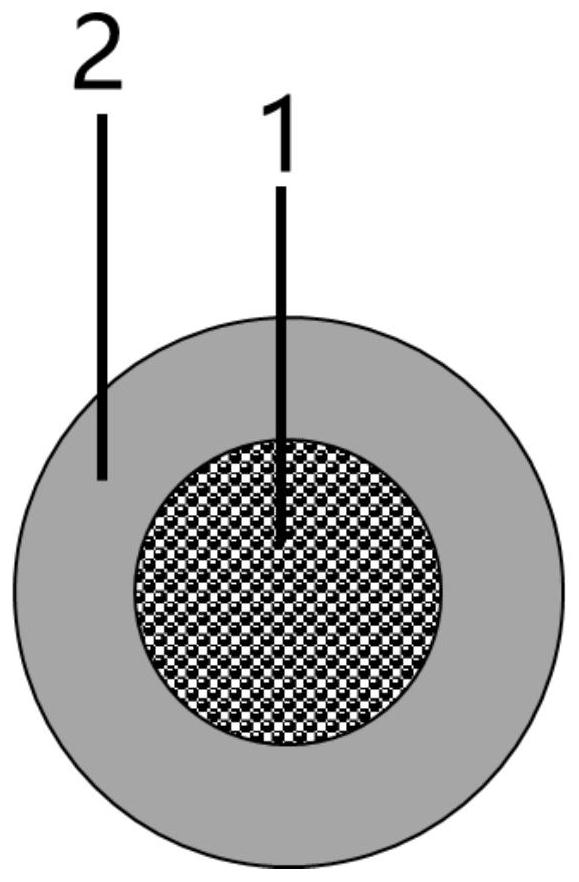

[0052] according to Figure 1-8 As shown, the embodiment of the present invention provides a novel electrochemical nano-pressure cavity technology, including a micro battery system and a control system. The miniature battery system includes battery positive and negative electrode materials that can desorb / intercalate cations, battery electrolyte materials 6, metal current collectors 8, etc. The battery negative electrode material 2 is provided with a core-shell structure, and the core-shell structure is used to coat the target. Study sample material 1. The control system generally includes a voltage-current control system 12 (such as an electrochemical workstation), an energiza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com