Claw-shaped circumferential equal-division type pouring system for aluminum alloy shell and pouring method of claw-shaped circumferential equal-division type pouring system

A pouring system and technology for aluminum alloys, applied in the field of low-pressure casting of aluminum alloys, can solve the problems of easy formation of hot junctions in the wall thickness, unfavorable alloy liquid feeding, affecting production efficiency, etc., so as to reduce shrinkage porosity defects and shorten solidification. Time, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the technical means, creative features, achieved goals and effects of the present invention, the present invention is further described below with reference to the accompanying drawings and specific embodiments.

[0025] refer to Figure 1-Figure 5 .

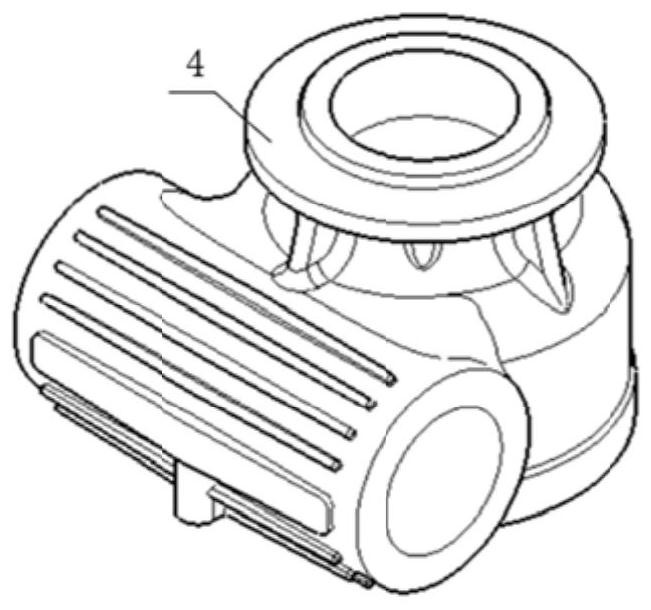

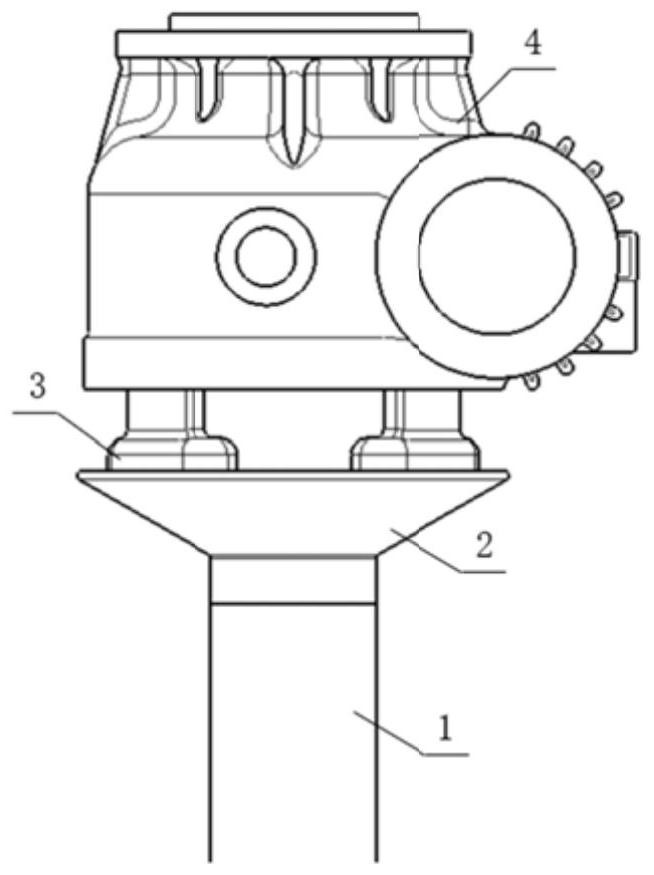

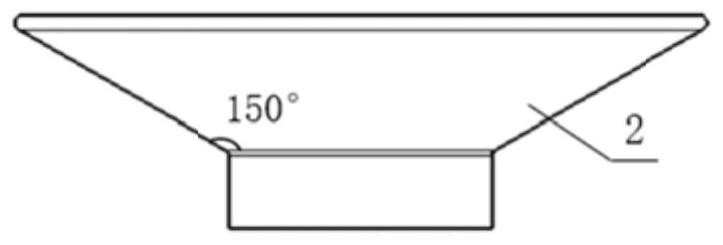

[0026] A claw-shaped circumferential equal-split pouring system for an aluminum alloy shell, the gating system is set on the symmetry axis of the bottom plane of the casting cavity; the structure of the aluminum alloy shell is as follows: figure 1 shown, the gating system is as figure 2 It includes a cylindrical liquid riser 1, a conical funnel-shaped runner 2, and a stepped inner runner 3; one end of the runner is connected with the liquid riser 1, and the other end is connected with the inner runner The runner 3 is connected, and the inner runner 3 is connected with the circular cavity at the bottom of the casting cavity. The liquid riser 1 is used to introduce the molten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com