A kind of SIC particle reinforced aluminum matrix composite material and preparation method thereof

A particle-reinforced aluminum and composite material technology, applied in the field of aluminum-based composite materials, can solve the problems of material tensile strength, yield strength elongation and hardness reduction, reduction of material mechanical properties, uneven distribution of particles, etc., to reduce the surface Tension, increase particle distribution uniformity, and improve the effect of distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

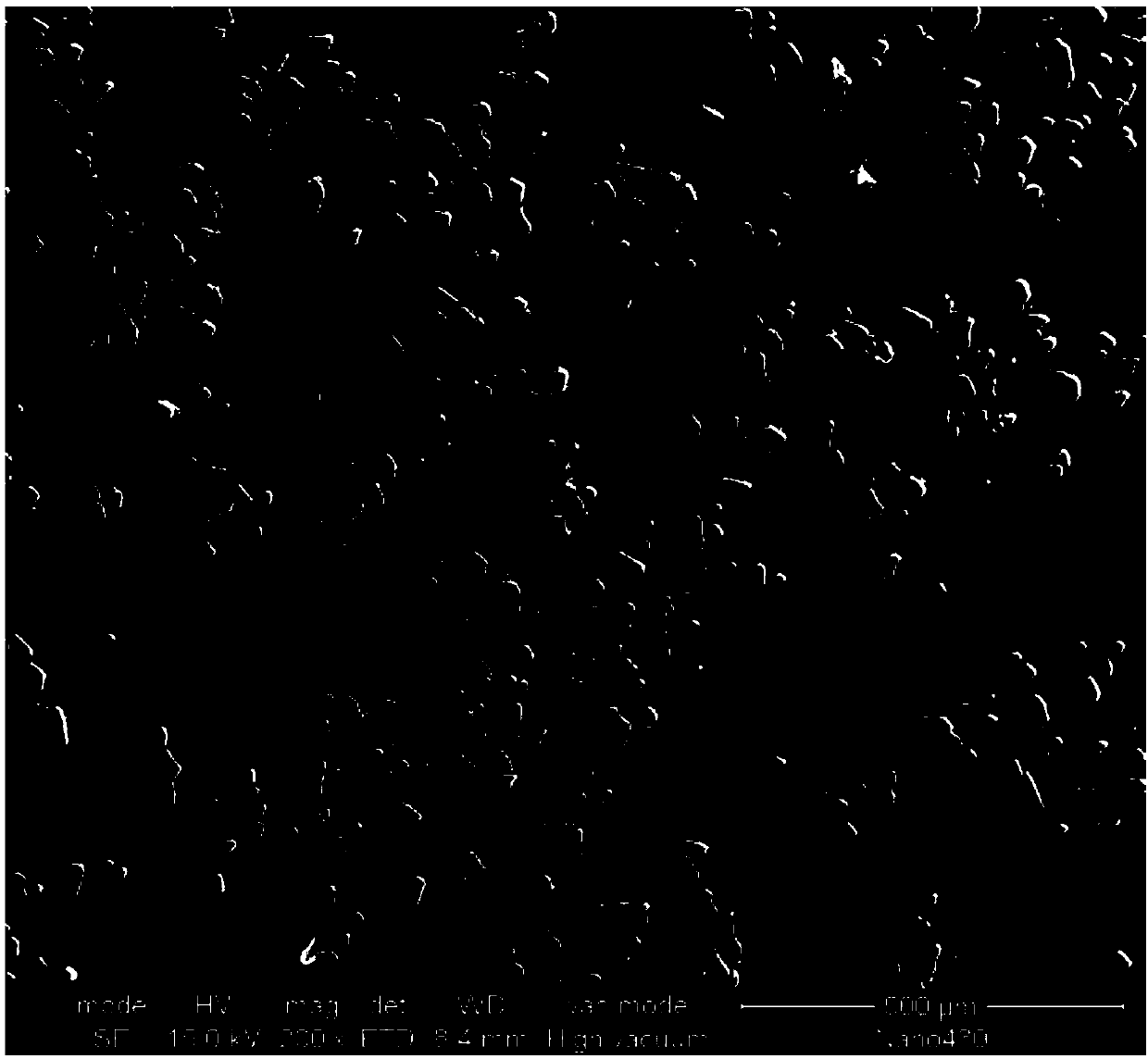

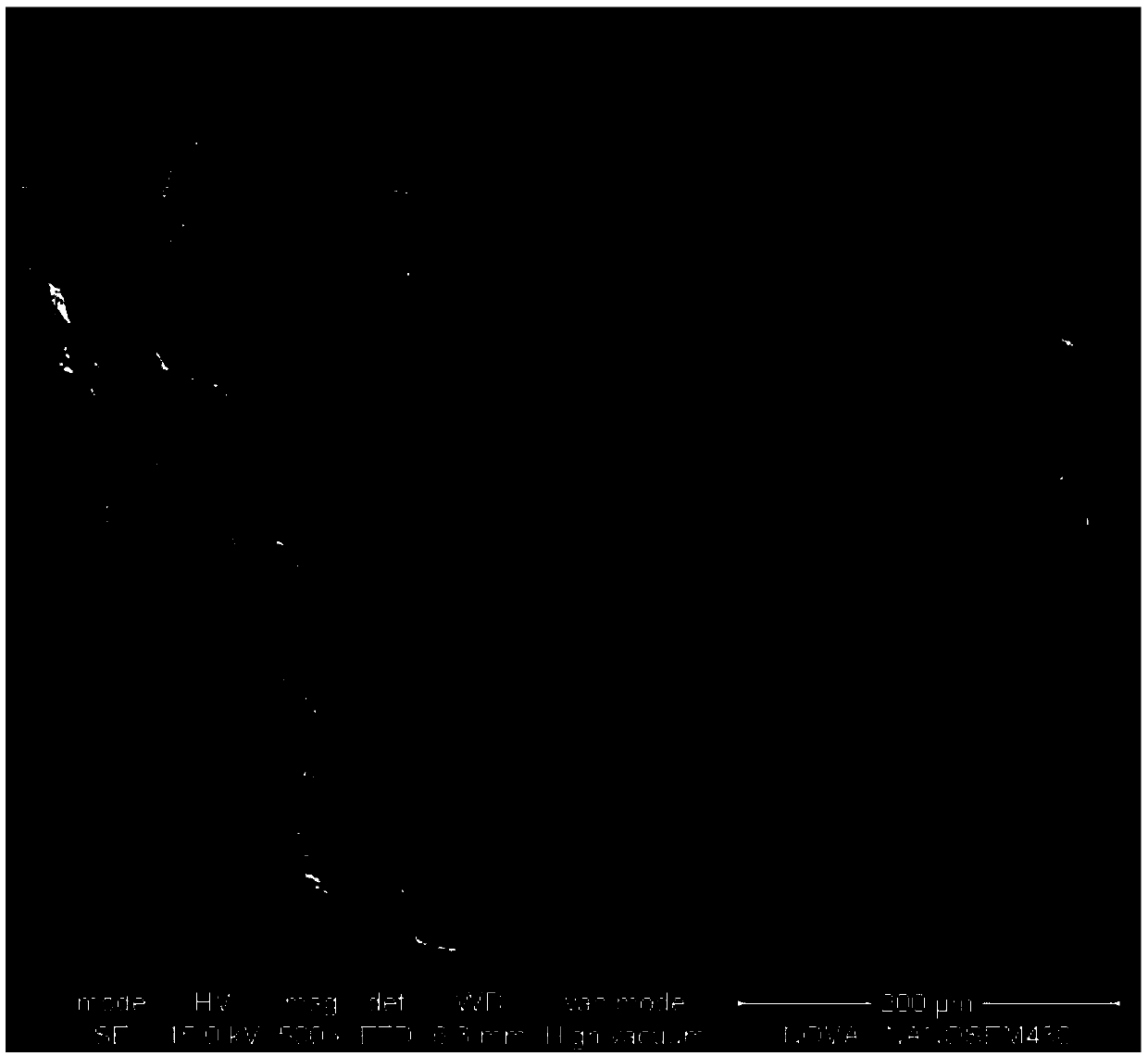

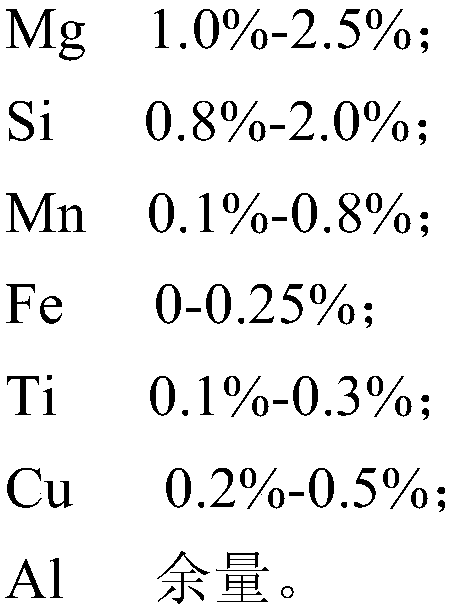

[0037] A SiC particle reinforced aluminum matrix composite material, the raw materials used are: industrial pure aluminum, pure Mg, Al-7% Si, Al-10% Mn, Al-5% Ti-B, Al-50% Cu, the particle size is 20 μm SiC particles. Among them, the composition of the matrix AlMgSi alloy is: Mg content 1.3%, Si content 0.92%, Mn content 0.1%, Fe content 0.03%, Ti content 0.1%, Cu content 0.3%, the rest is Al; SiC particle volume fraction is 10 %.

[0038] The preparation process of the SiC particle reinforced aluminum matrix composite material of this embodiment is as follows:

[0039] (1) Preparation and smelting of AlMgSi alloy: weigh appropriate amount of industrial pure aluminum, pure Mg, Al-7%Si, Al-10%Mn, Al-5%Ti-B, Al-50% according to the composition requirements of AlMgSi alloy Cu; raise the temperature of the crucible resistance furnace to 200°C and keep it warm for 1 hour. After the temperature is stable, add the weighed industrial high-purity aluminum, Al-7% Si, Al-10% Mn, and Al...

Embodiment 2

[0048] A SiC particle reinforced aluminum matrix composite material, the raw materials used are: industrial pure aluminum, pure Mg, Al-7% Si, Al-10% Mn, Al-5% Ti-B, Al-50% Cu, the particle size is 10 μm SiC particles. Among them, the composition of the matrix AlMgSi alloy is: Mg content 1.0%, Si content 0.8%, Mn content 0.8%, Fe content 0.25%, Ti content 0.1%, Cu content 0.5%, the rest is Al; SiC particle volume fraction is 13 %.

[0049] The preparation process of the SiC particle reinforced aluminum matrix composite material of this embodiment is as follows:

[0050] (1) Preparation and melting of AlMgSi alloy. Weigh an appropriate amount of industrial pure aluminum, pure Mg, Al-7% Si, Al-10% Mn, Al-5% Ti-B, Al-50% Cu according to the composition requirements of the AlMgSi alloy; raise the temperature of the crucible resistance furnace to 100 ℃ for 2 hours, after the temperature is stable, add the weighed industrial high-purity aluminum, Al-7%Si, Al-10%Mn, Al-50%Cu into t...

Embodiment 3

[0057] A SiC particle reinforced aluminum matrix composite material, the raw materials used are: industrial pure aluminum, pure Mg, Al-7% Si, Al-10% Mn, Al-5% Ti-B, Al-50% Cu, the particle size is 15 μm SiC particles. Among them, the composition of the matrix AlMgSi alloy is: Mg content 2.5%, Si content 2.0%, Mn content 0.5%, Fe content 0.15%, Ti content 0.3%, Cu content 0.2%, the rest is Al; SiC particle volume fraction is 9 %.

[0058] The preparation process of the SiC particle reinforced aluminum matrix composite material of this embodiment is as follows:

[0059] (1) Preparation and melting of AlMgSi alloy. Weigh an appropriate amount of industrial pure aluminum, pure Mg, Al-7%Si, Al-10%Mn, Al-5%Ti-B, Al-50%Cu according to the composition requirements of the AlMgSi alloy; raise the temperature of the crucible resistance furnace to 300 ℃ for 1 hour, after the temperature is stable, add the weighed industrial high-purity aluminum, Al-7%Si, Al-10%Mn, Al-50%Cu into the cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com