Stirring system and stirring method of stirring station

A mixing system and mixing station technology, applied in mixing plants, cement mixing devices, chemical instruments and methods, etc., can solve problems such as harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

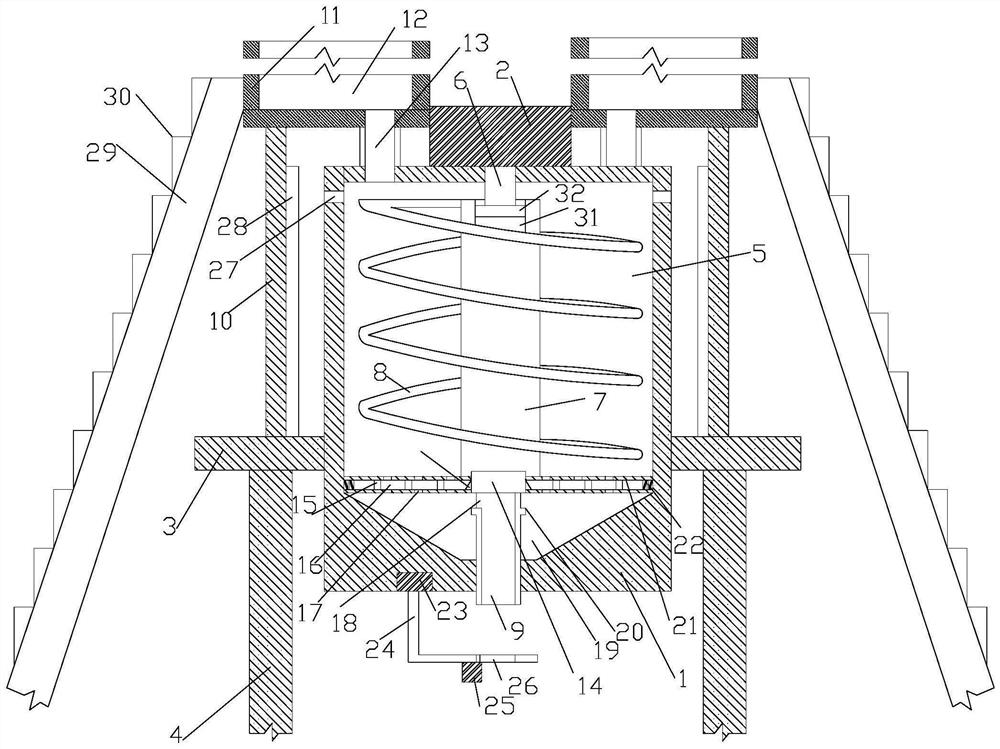

[0013] In order to make the technical means realized by the present invention, the creation features, the achievement of the purpose and the effect clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

[0014] The present invention proposes a mixing system of a mixing station, comprising a tank body 1, a motor 2 and a support platform 3, the tank body 1 is cylindrical, a support frame 4 is built on the bottom surface, and the support platform 3 is horizontally arranged on the On the support frame 4, the tank body 1 is arranged on the support platform 3, the support platform 3 is horizontal, the support platform has a first through hole, and the tank body 1 passes through the first through hole and fixedly welded on the inner wall of the through hole, the upper surface of the tank body 1 is higher than the support platform 3, the lower surface of the tank body 1 is lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com