Lining of packaging box

A packaging box and lining technology, applied in packaging, lining/internal coating, etc., can solve the problems of high price, complex process, single shape, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

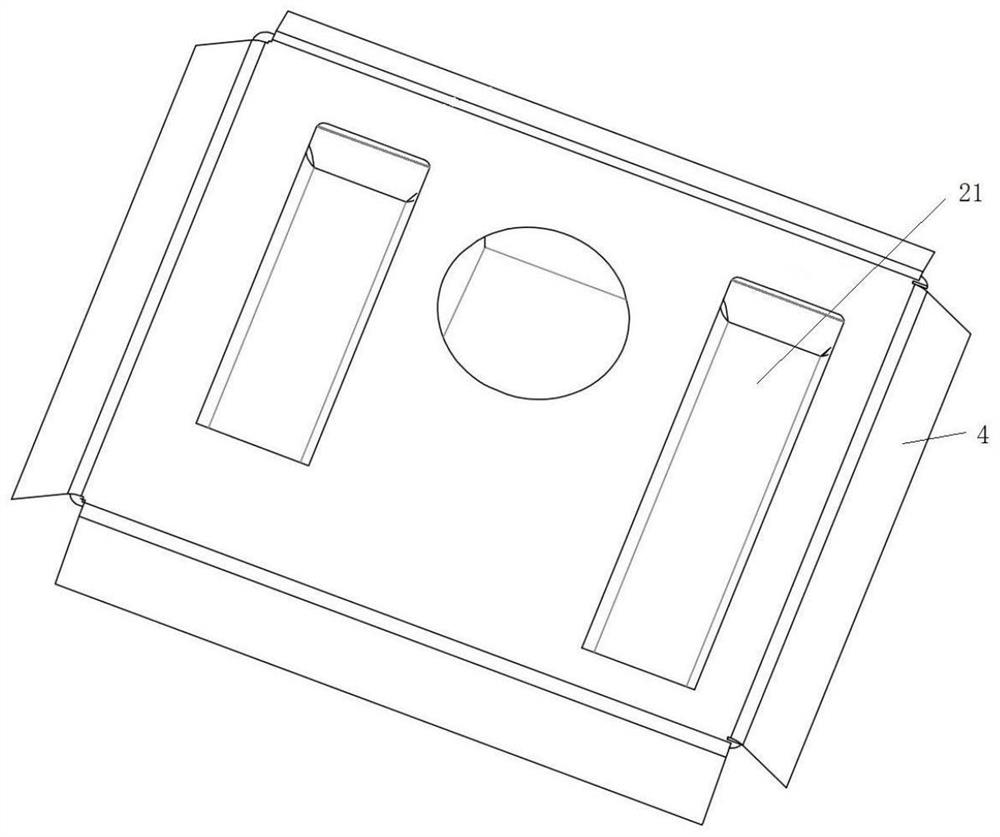

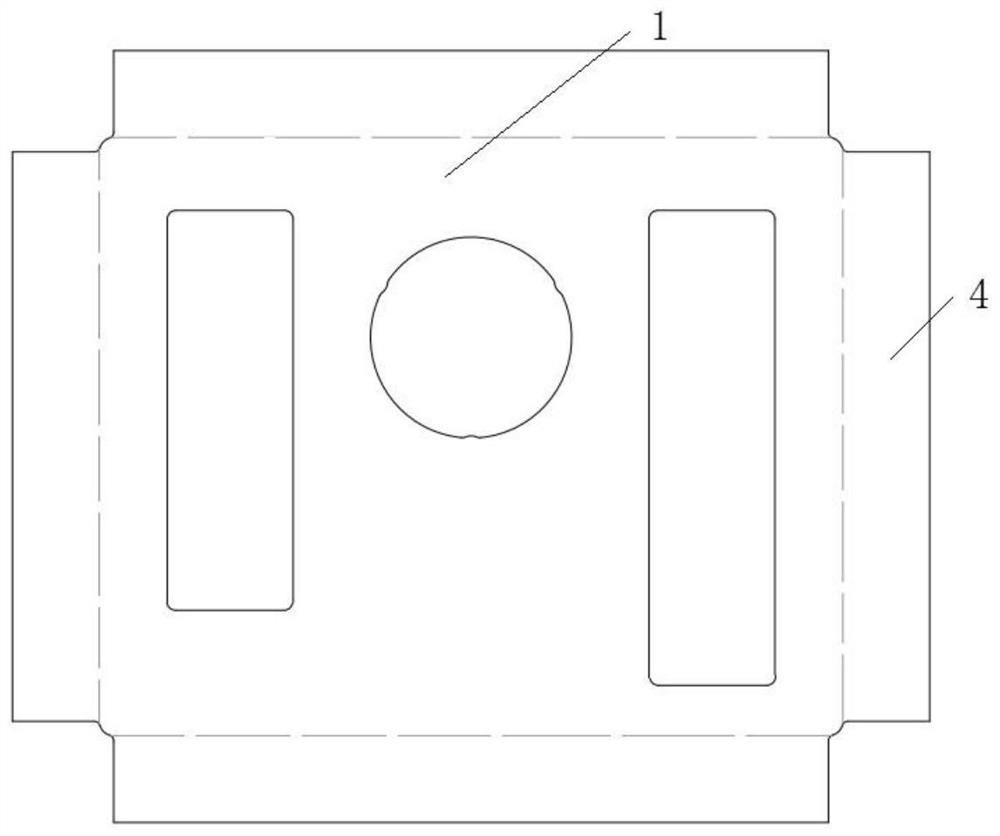

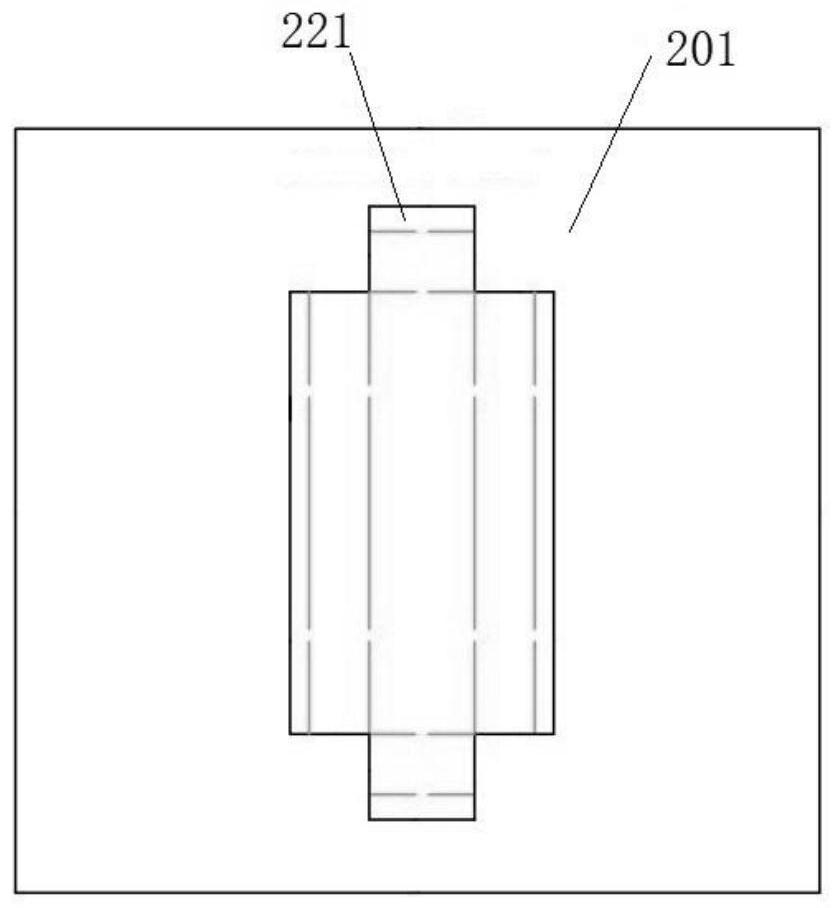

[0044] like figure 1 As shown, a kind of packing box lining includes upper layer cardboard 1, 3 layers of middle layer cardboard 2 and lower layer cardboard 3, upper layer cardboard 1, middle layer cardboard 2 and lower layer cardboard 3 are cardboards coated with polylactic acid, and the thickness of polylactic acid is 15-35mu; upper layer cardboard 1 and lower layer cardboard 3 are coated on one side, and middle layer cardboard 2 is coated on both sides; such as figure 2 and Image 6 , the solid line in the figure is the cutting line, the dotted line is the folding line, the shape and size of the upper layer cardboard 1 and the lower layer cardboard 3 are exactly the same, and there are side plates 4 connected to the four peripheries, and the side plates 4 can be folded into any angle; the upper layer cardboard 1 Die cut out the product shape, such as image 3 , Figure 4 and Figure 5 As shown, the middle-layer cardboard 2 includes a first middle-layer cardboard 201, a...

Embodiment 2

[0051] like Figure 7-10 As shown, a packing box lining includes an upper layer of cardboard 1, a middle layer of cardboard 2 and a lower layer of cardboard 3, the shape and size of the upper layer of cardboard 1 and the lower layer of cardboard 3 are exactly the same, and the four peripheries are connected with side panels 4, side The board 4 can be folded into any angle, the upper layer cardboard 1, the middle layer cardboard 2 and the lower layer cardboard 3 are cardboards coated with polylactic acid, the upper layer cardboard 1 and the lower layer cardboard 3 are coated on one side, the middle layer cardboard 2 is coated on both sides, The thickness of lactic acid is 15-35mu; as Figure 8-Figure 10 As shown, the solid line in the figure is the cutting line, and the dotted line is the folding line. The upper layer cardboard 1, the middle layer cardboard 2 and the lower layer cardboard 3 also include positioning holes 5; the upper layer cardboard 1 and the lower layer cardbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com