Compositions, methods of synthesis and uses for depositing materials

A composition and bonding technique used in the field of depositing materials on substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

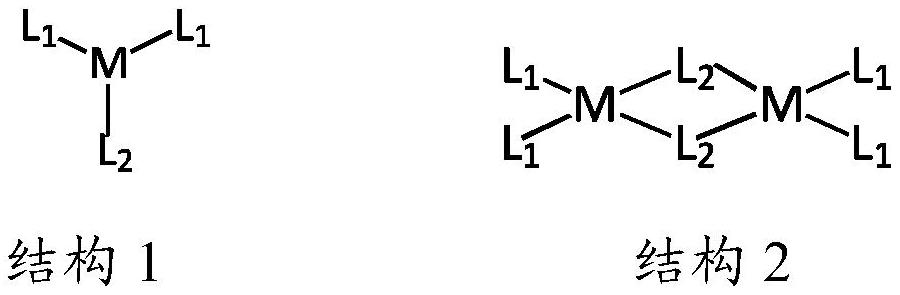

[0107] Example 2 Preparation of bis(tert-butyl)methylaluminum from trimethylaluminum

[0108] Similarly, the commercially available reagent AlMe can be used according to the following reaction scheme (Scheme II) 3 ,AlCl 3 and tBuLi to prepare tBu2AlMe. A 4-step synthesis method similar to Example 1 can be used, with only differences in each step compared to Example 1.

[0109]

[0110] Scheme II

[0111] Step 1: Combine AlMe in a 1:2 molar ratio 3 and AlCl 3

[0112] AlMe 3 (100 mL, 2.0 M hexane, 200 mmol) and AlCl 3 (400 mmol) were combined in a molar ratio of 1:2 and stirred until the system reached equilibrium.

[0113] Step 2: Add tBuLi

[0114] Under the same conditions as the original procedure above, tBuLi (about 1.7M hexane, about 700 mL, 1.20 mol) was added.

[0115] Steps 3 and 4

[0116] The final steps required to isolate the product can be accomplished as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com