Broken soft thin coal seam gas extraction directional long drilling construction drilling tool assembly and method

A gas extraction and drilling tool combination technology, applied in directional drilling, drilling tools, gas discharge, etc., can solve the problems of easy collapse, low porosity, affecting work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

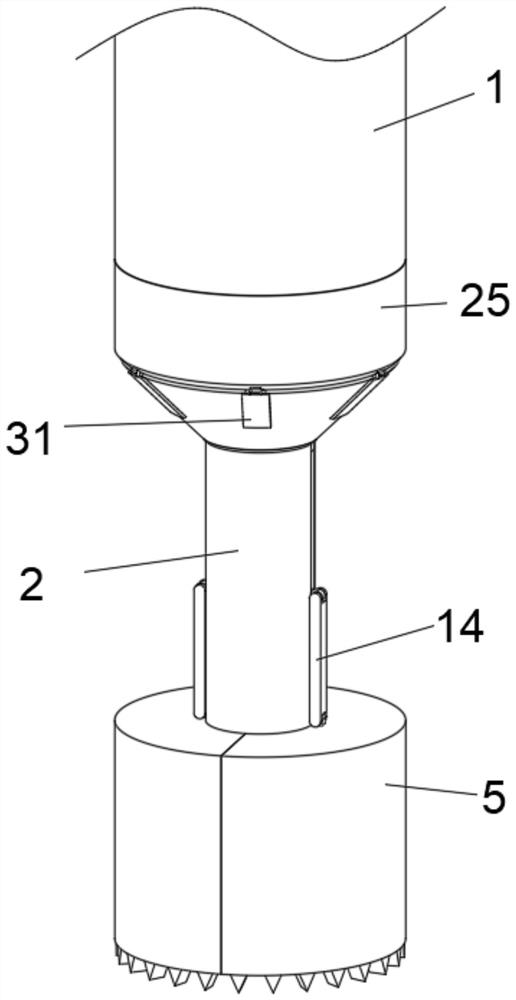

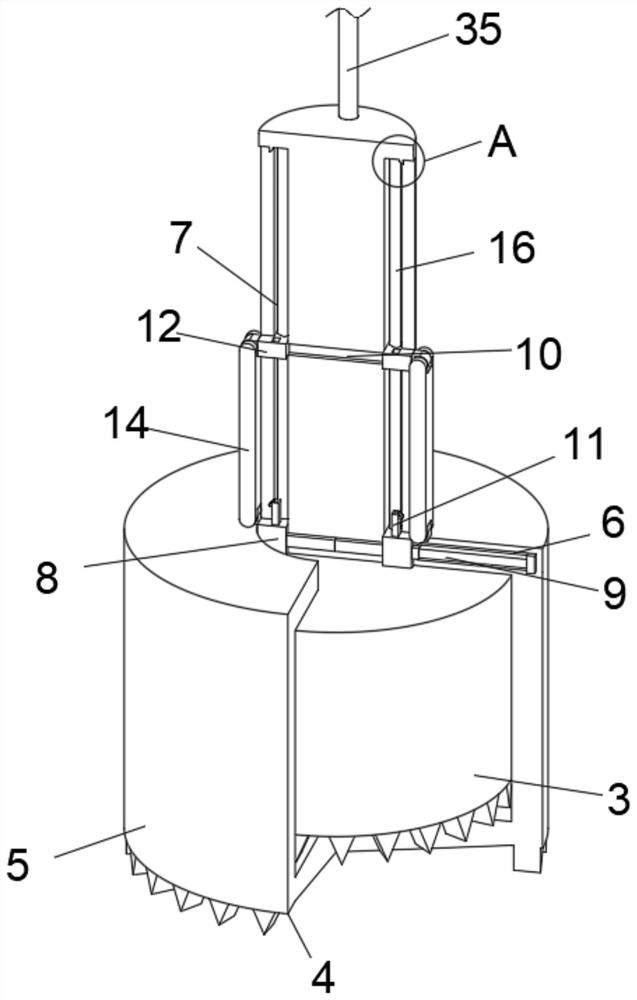

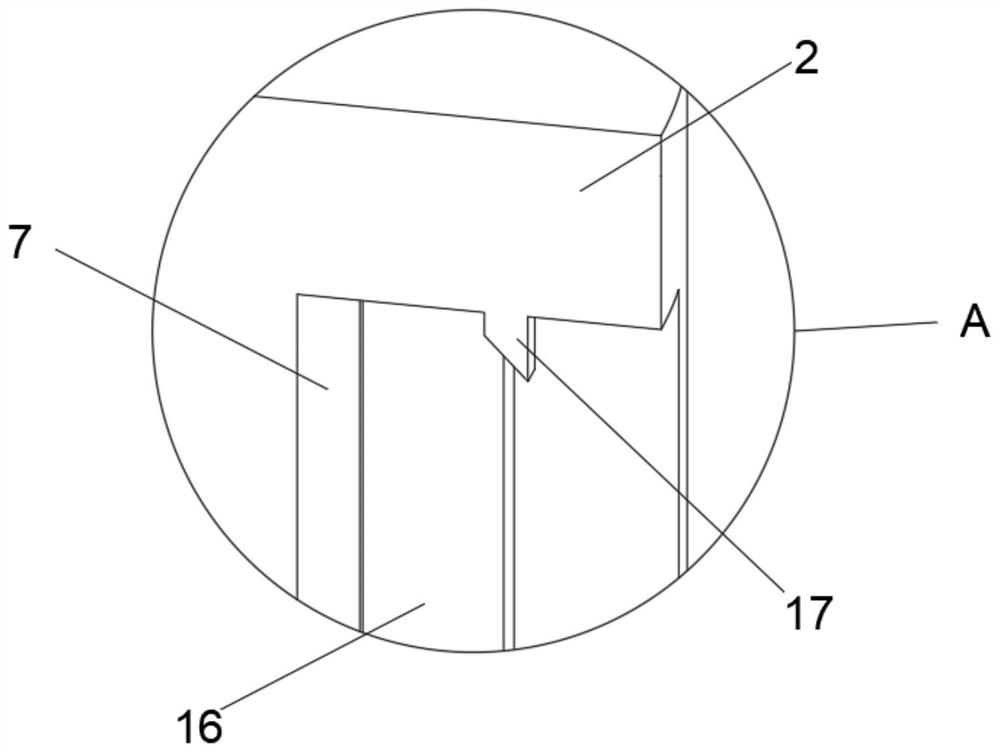

[0036] see Figure 1-7 , the present invention provides a kind of technical scheme:

[0037] A drilling tool assembly and method for directional long drilling for gas extraction in crushed and thin coal seams, comprising a drill pipe 1, a transmission shaft 2, one end of the transmission shaft 2 is provided with a drill bit A3, the outside of the drill bit A3 is provided with a drill bit B4, and the drill bit B4 includes at least a There are two combined blocks 5. The combined block 5 is provided with a guide groove 6 inside, and the outer wall of the transmission shaft 2 is provided with at least two sliding grooves 7. The inner lower side of the sliding groove 7 is slidably connected with a sliding block A8, and the middle of the sliding block A8 is provided with an extension. Assembly 9, one side of the extension assembly 9 is located inside the guide groove 6, the middle of the transmission shaft 2 is provided with two upper and lower notches 10, one side of the extension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com