High-efficiency energy-saving large-flow self-priming pump with wear-resistant middle-opening impeller

A high-efficiency, energy-saving, high-flow technology, which is applied to the components, pumps, driving pumps, etc. of the pumping device for elastic fluids, can solve the problems of energy waste, impeller and vane damage, and increase the use load of the self-priming pump impeller, etc. Achieve the effect of improving wear resistance, improving service life and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

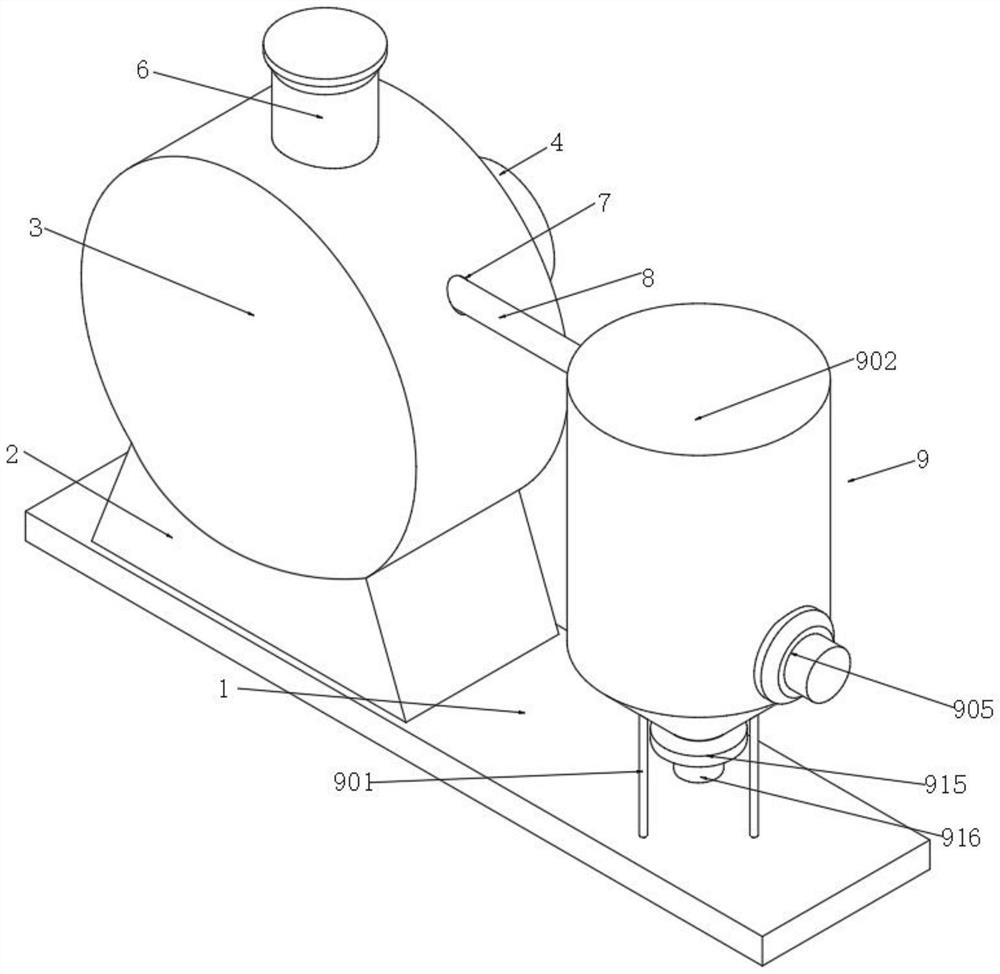

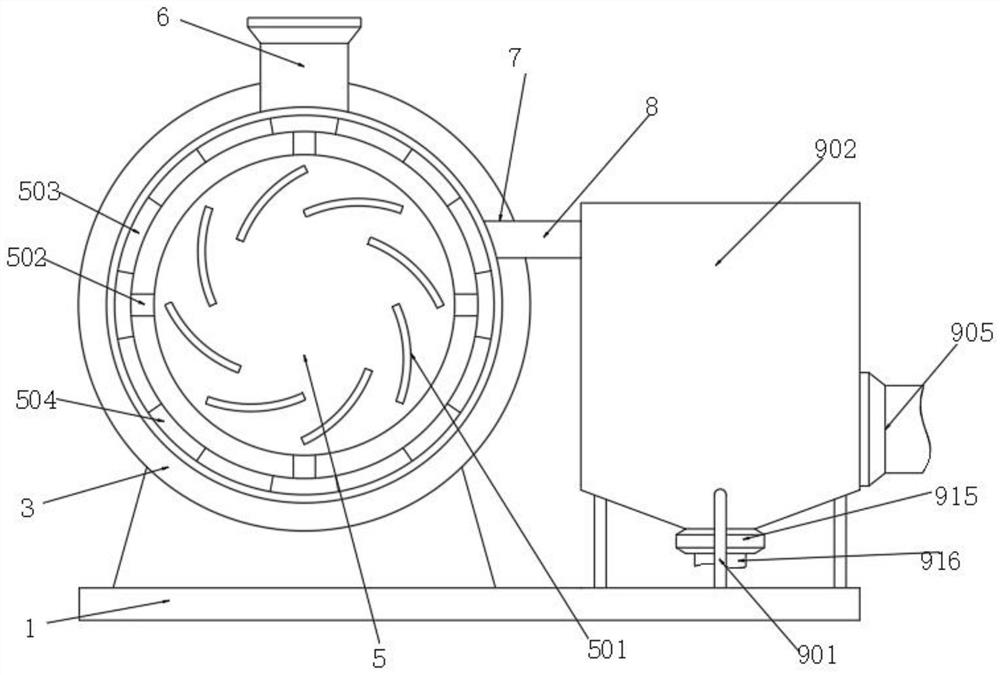

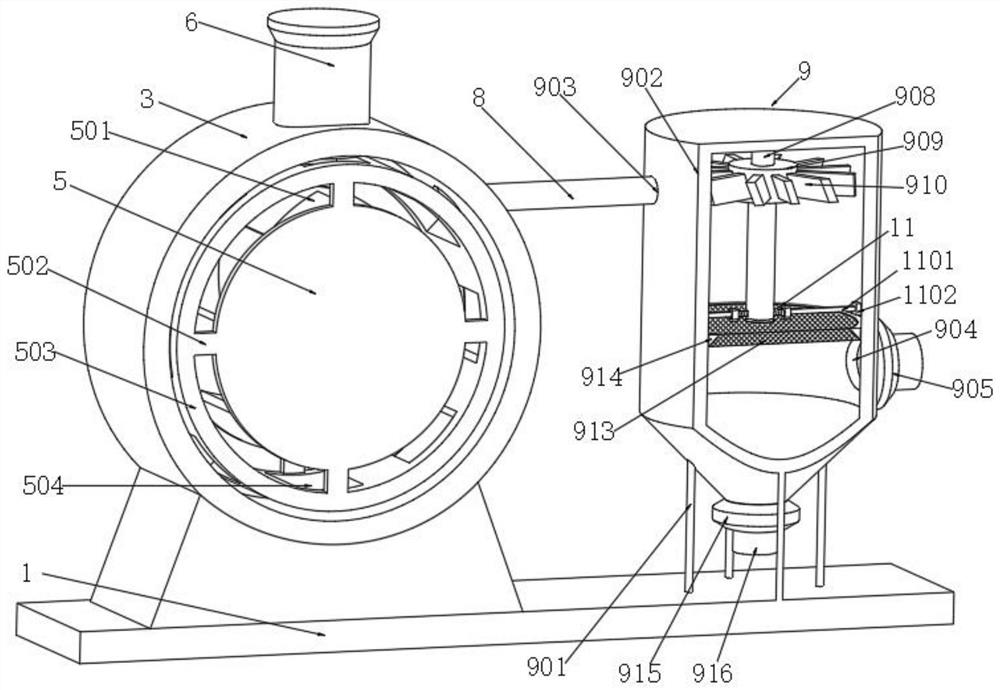

[0041] Example: as Figure 1-Figure 10 As shown, the present invention provides the following technical solutions: a high-efficiency, energy-saving, large-flow self-priming pump with a wear-resistant mid-open impeller, the high-efficiency, energy-saving, large-flow self-priming pump with a wear-resistant mid-open impeller comprises a plate body 1, and the plate body 1 A base 2 is fixedly installed on the base, a pump body 3 is fixedly installed on the base 2, a drive motor 4 is fixedly installed on the pump body 3, and the output shaft of the drive motor 4 penetrates the drive hole on the pump body 3, and An impeller 5 is fixedly installed on the output shaft of the drive motor 4, and the impeller 5 is located in the pump body 3. The pump body 3 is fixedly connected with a water outlet pipe 6, and the pump body 3 is provided with a water inlet 7. The water inlet 7 is connected to the filter assembly 9 through the water inlet pipe 8. When the water suction operation is required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com