Equipment fault monitoring method and device, equipment and medium

A technology of equipment failure and equipment data, which is applied in the field of intelligent operation and maintenance management of substations, can solve problems such as high cost, low efficiency, and long processing time, and achieve the effects of efficient processing, improved computing efficiency, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

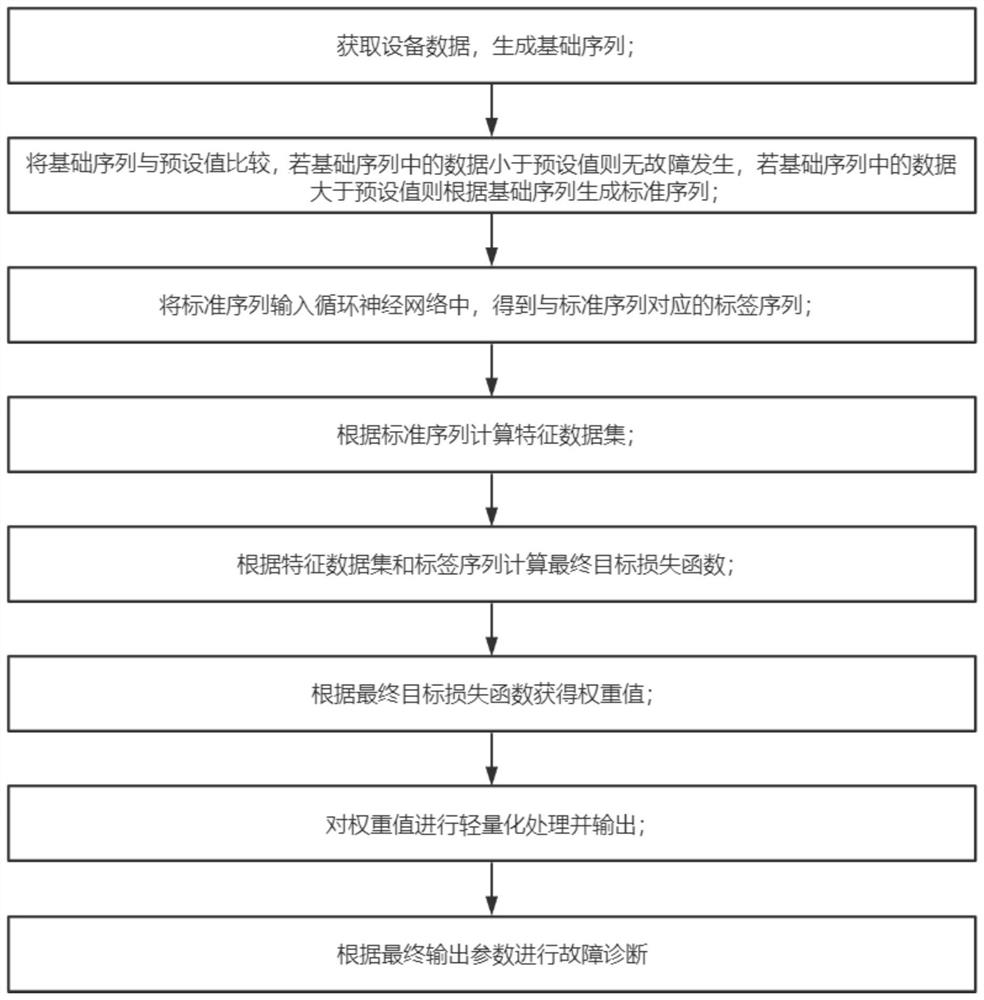

[0079] like figure 1 As shown, a method for monitoring equipment failure includes the following steps:

[0080] Through real-time acquisition of multi-parameter sensors, the data of substation equipment is obtained, and the basic sequence {x 1 ,x 2 ,x 3 ...x n }, equipment data includes transformer partial discharge, temperature, noise, GIS partial discharge, temperature and humidity of sink control cabinet, etc.;

[0081] Perform data judgment on the base sequence, compare the data in the base sequence with the preset value, if the data in the base sequence is less than the preset value, no fault occurs, if the data in the base sequence is greater than the preset value, generate according to the base sequence Standard sequence; the default value is the minimum value of the equipment data at the time of the historical fault; if the data judgment of the transformer temperature data is performed, the transformer temperature data obtained this time will be x 温 Compare with t...

Embodiment 2

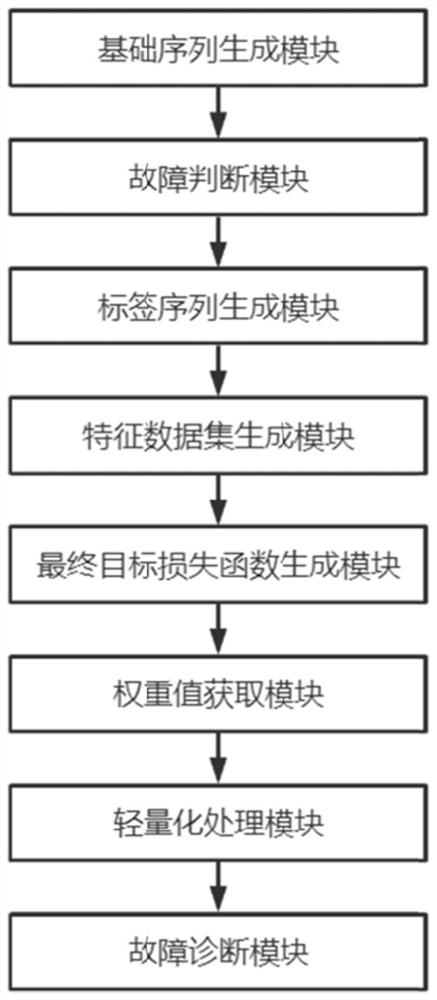

[0122] like figure 2 As shown, an equipment fault monitoring device includes:

[0123] Basic sequence generation module: used to obtain device data and generate basic sequences;

[0124] Fault judgment module: used to compare the base sequence with the preset value, if the data in the base sequence is less than the preset value, no fault occurs, and if the data in the base sequence is greater than the preset value, a standard sequence is generated according to the base sequence;

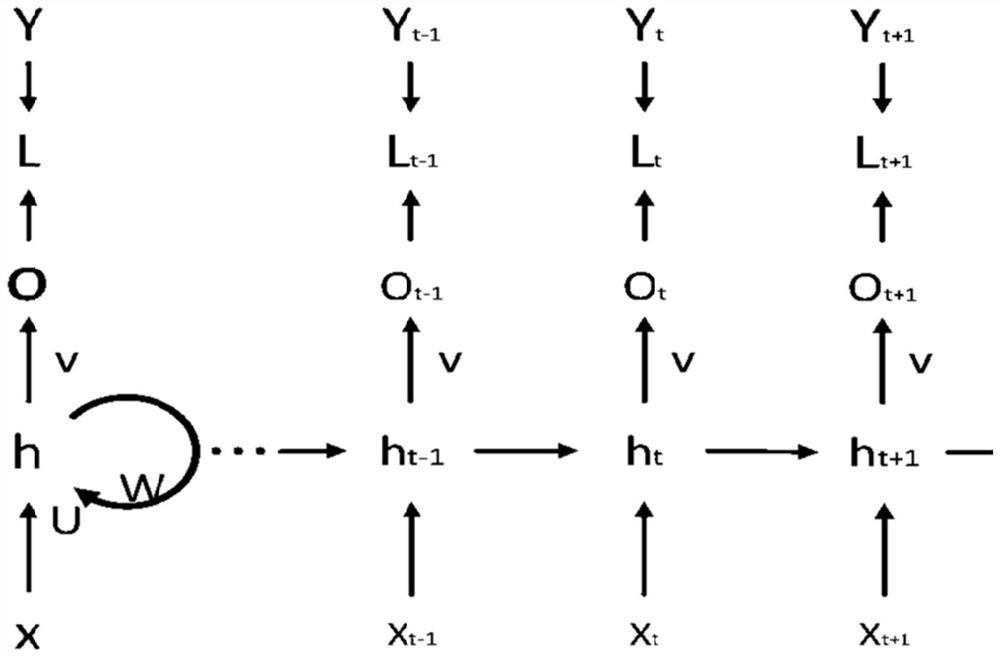

[0125] Label sequence generation module: used to input the standard sequence into the recurrent neural network to obtain the label sequence corresponding to the standard sequence;

[0126] Feature dataset generation module: used to calculate feature datasets based on standard sequences;

[0127] Final objective loss function generation module: used to calculate the final objective loss function based on the feature dataset and label sequence;

[0128] Weight value acquisition module: used to obta...

Embodiment 3

[0132] A computer device includes a memory, a processor, and a computer program stored in the memory and executable on the processor, and the above-mentioned method for monitoring equipment failure when the processor executes the computer program.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com