Substrate structure and electronic device

A substrate structure and substrate technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of environmental pollution of electroplating solution, complex process, high cost, etc., and achieve the effect of simple production process, wide application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The substrate structure and the electronic device according to the preferred embodiments of the present invention will be described below with reference to the related drawings, wherein the same components will be described with the same reference numerals.

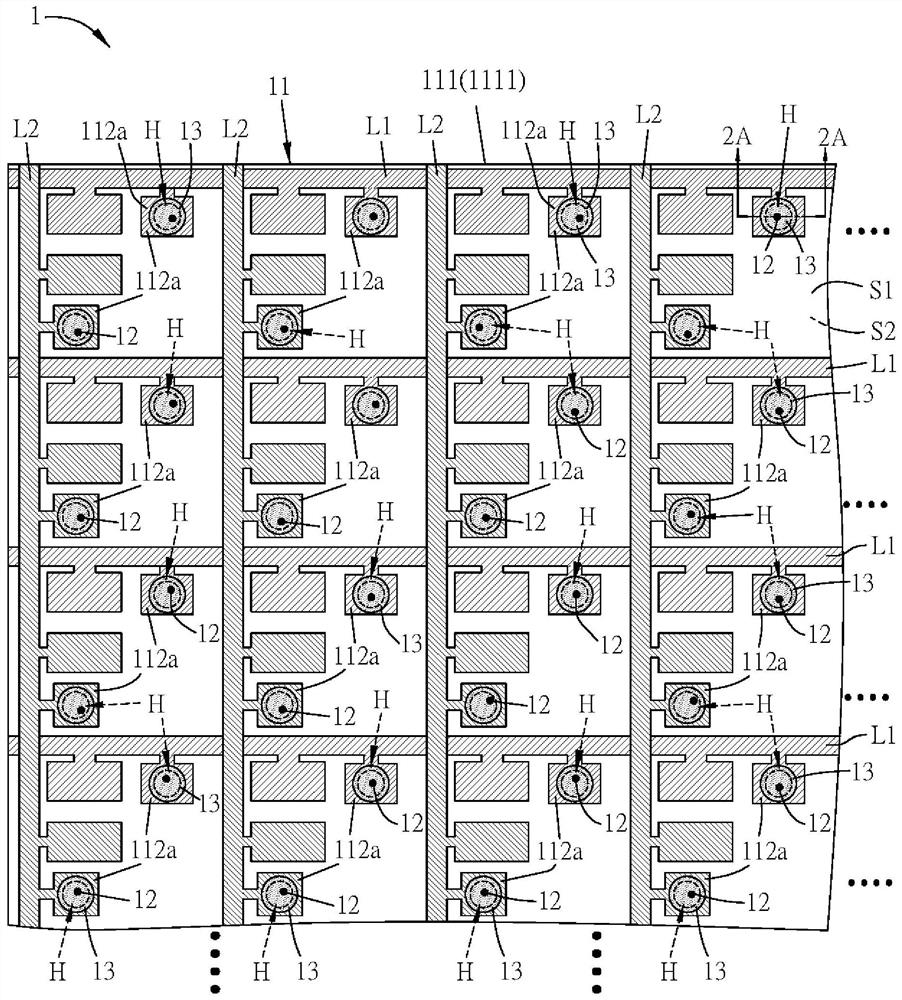

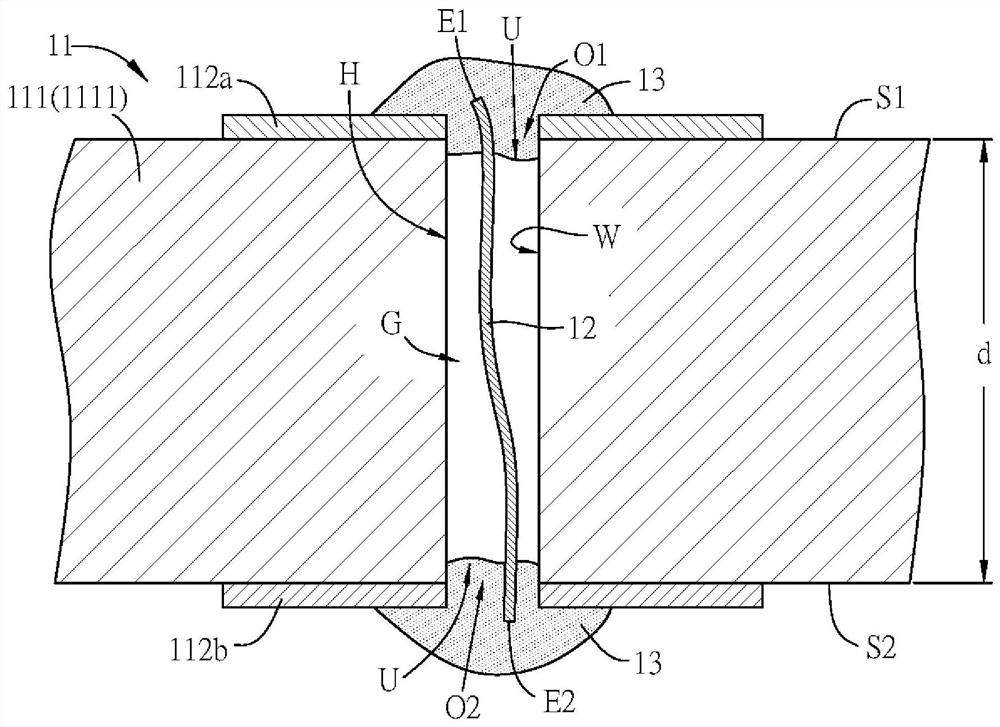

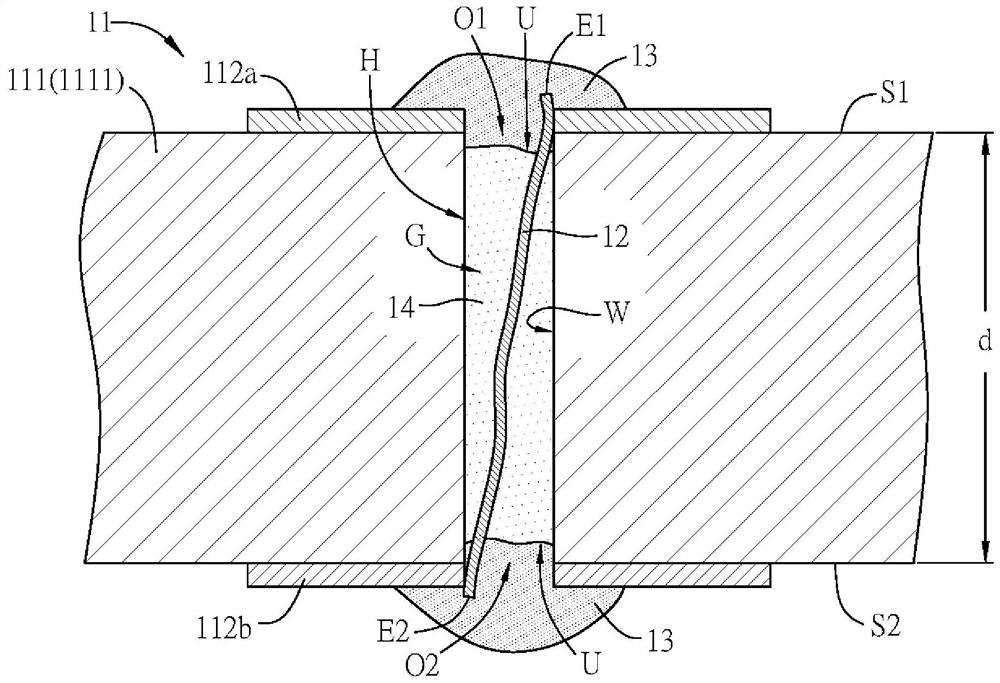

[0061] figure 1 is a schematic diagram of a substrate structure according to an embodiment of the present invention, and 2A to 2C respectively figure 1 Schematic cross-sectional views of different embodiments of the substrate structure along the secant line 2A-2A. like figure 1 As shown, the substrate structure in this embodiment is an active matrix (AM) substrate structure as an example, but it is not limited to this. In different embodiments, the substrate structure may also be passive Matrix (Passive Matrix, AM) substrate structure, or other types of substrate structure.

[0062] Please refer to figure 1 , 2A to 2C As shown, the substrate structure 1 includes a substrate 11 , a plurality of conductive li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com