Container type battery replacing station and battery replacing method thereof

A container-type, power-swap technology, applied in charging stations, electric vehicles, transportation and packaging, etc., can solve the problems of inability to flexibly change the scale of power-swap power stations, high construction cost of fixed power-swap power stations, and high difficulty in disassembly and assembly, and improve space utilization. efficiency, simple installation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

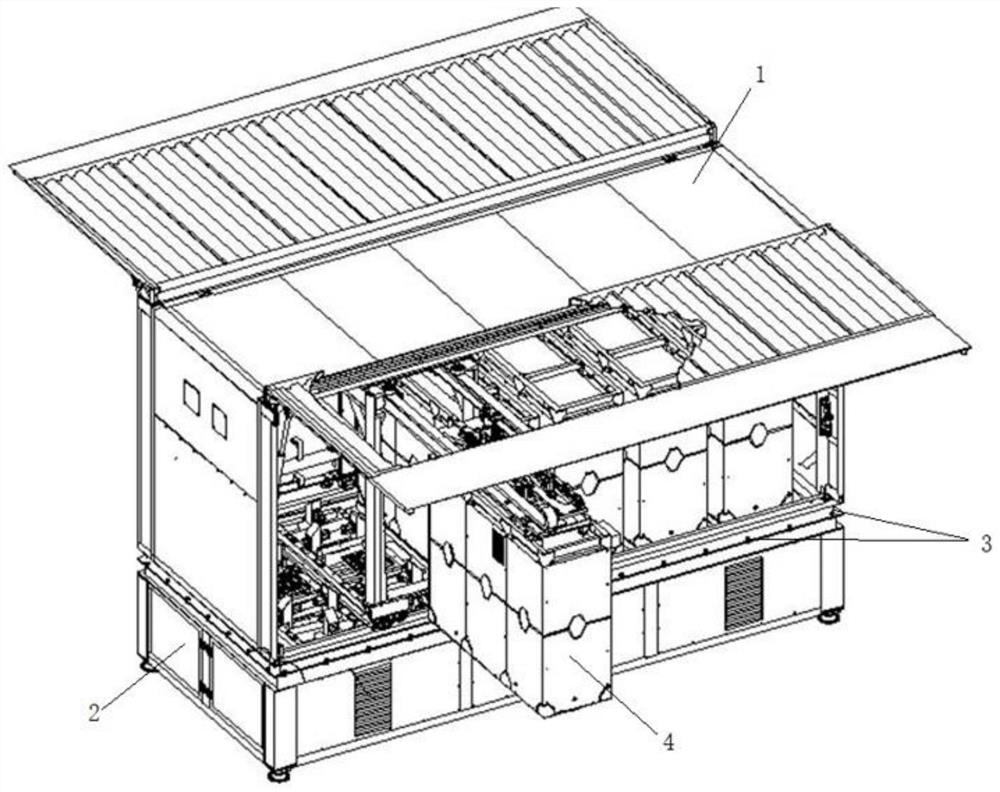

[0066] see Figure 1 to Figure 22 As shown, the embodiment of the present application provides a container-type power exchange station, including: a lower box body 2, an upper box body 1 and a power exchange mechanism. A control device 26 is arranged in the lower box 2 , and a plurality of battery box bases 22 are arranged on the lower box 2 along the length direction. The upper case 1 is detachably connected to the lower case 2 , and the upper case 1 and the lower case 2 are enclosed to form a cavity for accommodating the battery case base 22 . The power exchange mechanism is movably disposed in the cavity, and the power exchange mechanism is connected with the control device 26 . The control device 26 can control the power exchange mechanism to perform the power exchange action.

[0067] The containerized power exchange station of the present application includes a lower box body 2 and an upper box body 1. During the assembly process, the lower box body 2 and the upper box...

Embodiment 2

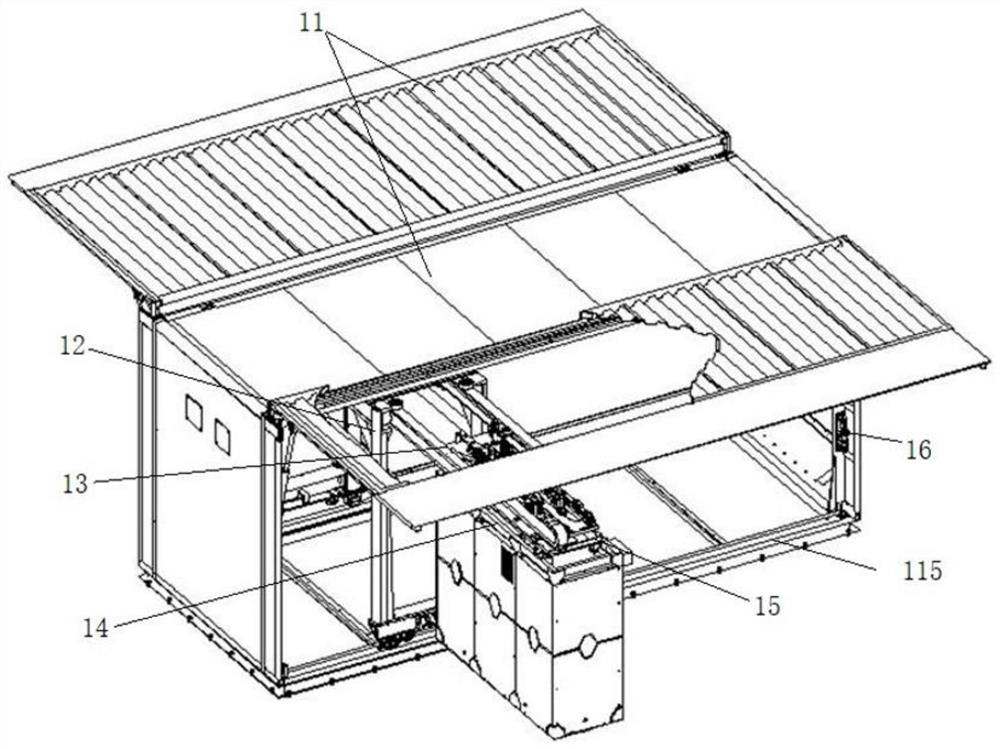

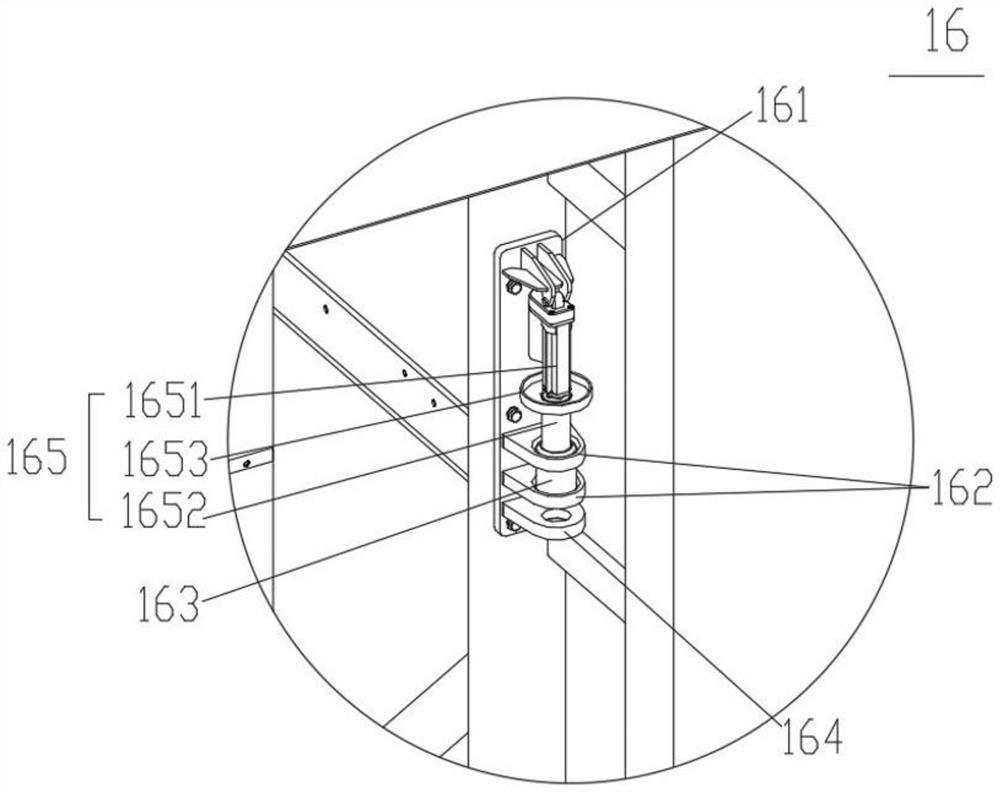

[0090] see figure 2 and image 3 As shown, the second embodiment of the present application further describes the containerized power exchange station in detail on the basis of the first embodiment. The containerized power exchange station further includes an anchoring device 16 for locking or releasing the power exchange mechanism on the power exchange station. The guide sleeve 163 is connected to the mounting plate 161 , and the guide sleeve 163 has a guide groove therethrough. The support member 164 is connected to the mounting plate 161 , and the support member 164 has a limit hole. The telescopic device 165 includes a fixed part 1651 and a telescopic part 1652 , the fixed part 1651 is connected to the mounting plate 161 , and the telescopic part 1652 is movably connected to the fixed part 1651 . The anchoring device 16 has a locked state and a released state. In the released state, the telescopic portion 1652 is accommodated in the guide groove; in the locked state, the...

Embodiment 3

[0104] see image 3 As shown, on the basis of the above-mentioned embodiments, the third embodiment of the present application further describes a power exchange station, which further includes: a hydraulic pipe accommodating device 171 and a movable hydraulic pipe. The power exchange mechanism is movably connected to the power exchange station, the power exchange mechanism can translate along the length direction of the power exchange station, and the power exchange mechanism has a hydraulic drive mechanism 128 . The hydraulic pipe accommodating device 171 is connected to the power exchange station. The movable hydraulic pipe is partially accommodated in the hydraulic pipe accommodating device 171 , and the movable hydraulic pipe is connected to the hydraulic drive mechanism 128 . When the power exchange mechanism is moving away from the hydraulic pipe accommodating device 171 , the movable hydraulic pipe can be driven to extend out of the hydraulic pipe accommodating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com