Water-based colored latex ink suitable for Epson nozzle

A common nozzle and ink technology, applied in inks, applications, household utensils, etc., can solve the problems of poor film-forming property, easy ink flow, poor fastness on the medium, and easy clogging of latex ink, etc., to achieve bright colors and high fastness , good standby performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

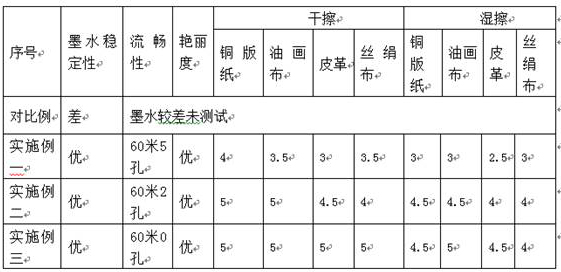

Examples

Embodiment 1

[0037] Weigh by mass: 30 parts of pigment dispersion, 5 parts of Risin VINYBLAN 701, 25 parts of Huajinsi M6617, 10 parts of Mitsui W-6110, 16.4 parts of humectant triethylene glycol, 10 parts of propylene glycol, 2 parts of 1.2-hexanediol Alcohol, 1.5 parts Chemours FS-3100, 0.1 part biocide.

Embodiment 2

[0039] Weigh by mass: 30 parts of pigment dispersion, 5 parts of Nissin CHALINE E-790, 5 parts of Nissin VINYBLAN 701, 20 parts of Huajinsi M6617, 10 parts of Mitsui W-6110, 15 parts of humectant triethylene glycol, 11.4 parts parts propylene glycol, 2 parts 1,2-hexanediol, 1.5 parts Chemours FS-3100, 0.1 part biocide.

Embodiment 4

[0041] Weigh by mass: 30 parts of pigment dispersion, 5 parts of Nissin CHALINE E-790, 5 parts of Nissin VINYBLAN 701, 20 parts of Huajinsi M6617, 10 parts of Mitsui W-6110, 15 parts of humectant triethylene glycol, 11.4 parts parts propylene glycol, 1.5 parts 1.2-hexanediol, 1.5 parts Chemours FS-3100, 0.5 parts WataChem WA245, 0.1 parts biocide.

[0042] The ink of the example on the machine was printed for 60 meters with Guangzhou Hongyue 4720 nozzle printer, and the test medium performed well, forming a film well, and no ink flowed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com