Arched cavity fluid flowing floor slab, manufacturing method and flowing pipe

A technology of fluid flow and flow pipes, which is applied to floors, manufacturing tools, building structures, etc., can solve the problems of difficulty in meeting low-carbon requirements, smoke exhaust, high ventilation costs, airflow pressure loss, etc., to reduce the amount of concrete and shorten the Construction period and effect of reducing local pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

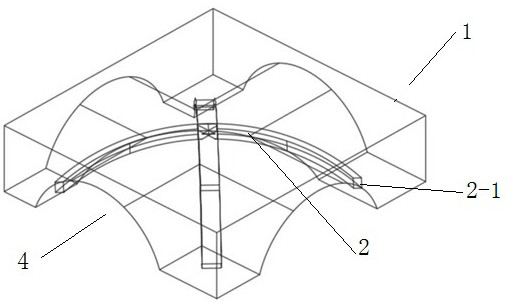

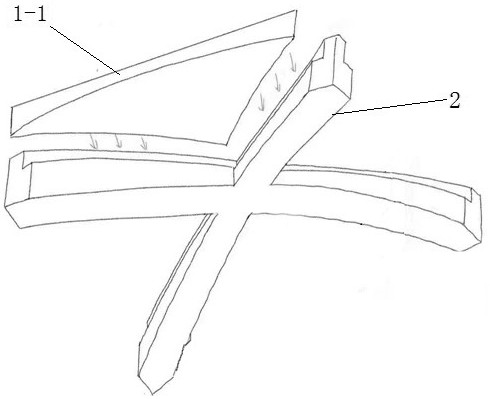

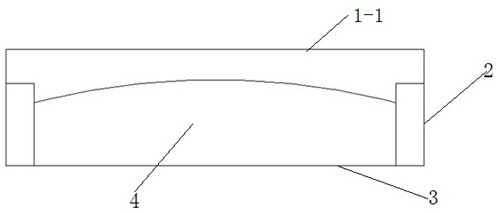

[0039] like figure 1 As shown, an arched cavity fluid flow floor 1, the floor 1 is a cube structure, a horizontal top plate is arranged above the floor 1, the top plate can be used as the floor or roof plate of the upper floor, and the bottom surface of the floor 1 is provided with an arc The side of the arc-shaped groove is provided with a groove 4 that communicates the groove with the outside of the floor 1. The depth of the groove 4 matches the depth of the groove, and the arc-shaped groove corresponds to the four lateral positions of the floor 1. There is a groove 4 communicating with the side surface. There is a supporting surface at the bottom of the floor 1, and the floor 1 and the supporting surface form a box structure with a cavity and a pipeline inside. The angle is consistent with the radian of the groove, and the two arched beams 2 arranged in a cross can form an included angle of 30° to 90° as required, and the two arched beams 2 are both arched structures with ...

Embodiment 2

[0043] The manufacturing method of the arched cavity fluid flow floor slab, the manufacturing steps are as follows:

[0044] S1. According to the size in the design requirements, make the mold of the arc-splitting plate and the arched beam plate 2, inject concrete into the mold, and continue to stir and shake until the concrete is uniform without air bubbles, and continue to add concrete until it is full;

[0045] S2. After the concrete is solidified, demould, and take out four arc-parting slabs and two arched beam slabs 2;

[0046] S3. Assemble the four arc-shaped slabs and the two arched beam slabs 2. When splicing, build both sides of one arc-shaped slab on the two arched girder slabs 2, and then place it with the first arc-shaped slab. The arc-splitting plate position in the symmetrical position, and finally place the remaining two arc-splitting plates;

[0047] S4. Inject adhesive into the gap between the assembled four arc-parting plates and the root arch beam plate 2 to ...

Embodiment 3

[0054] like Figure 5 As shown, a flow tube is formed according to an arched cavity fluid flow floor, the flow tube is formed by arranging a plurality of floor slabs 1, one end of the flow tube is located at the edge of the floor, and the floor 1 located at the edge of the floor is close to the floor. One side of the wall is provided with a through pipe that communicates with the outside, and the through pipe is provided with a pressurizing device. If the flowing medium in the flow pipe is gas, the pressurizing device can be an air pump, a fan, etc.; if the flowing medium in the flow pipe is a liquid Then the pressurizing device is a high-pressure water pump; an opening is provided in the ceiling 3 of the floor 1 slab at the other end of the flow pipe, and the opening 4 of the butt joint between two adjacent floor slabs 1 in the flow tube is aligned to form a fluid flow channel, and the floor 1 The outer sides of the openings 4 corresponding to both sides of the fluid flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com