Water catchment prevention and control method for coal-pillar-free goaf

A gob-free, coal-pillar-free technology, applied in drainage, mining equipment, earthwork drilling, etc., can solve problems such as water catchment, achieve broad application prospects, low cost of water prevention and control, and ensure long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

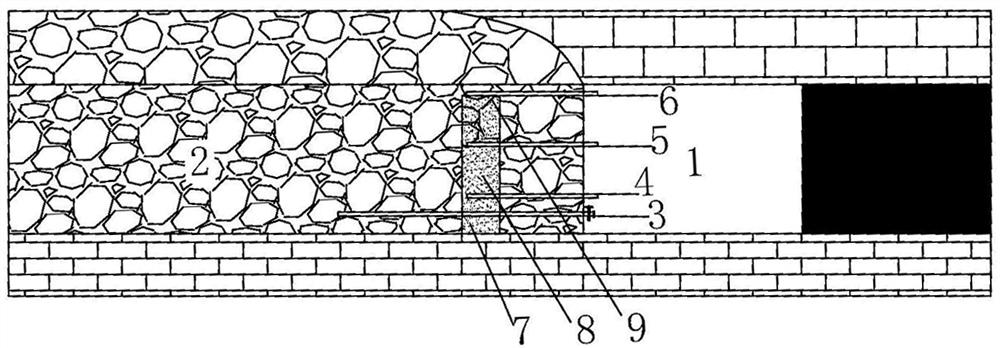

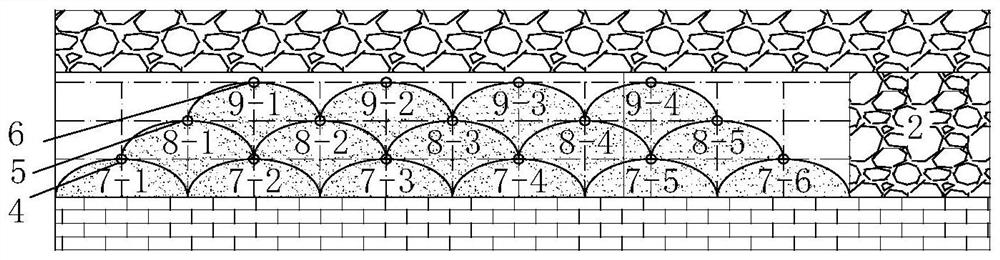

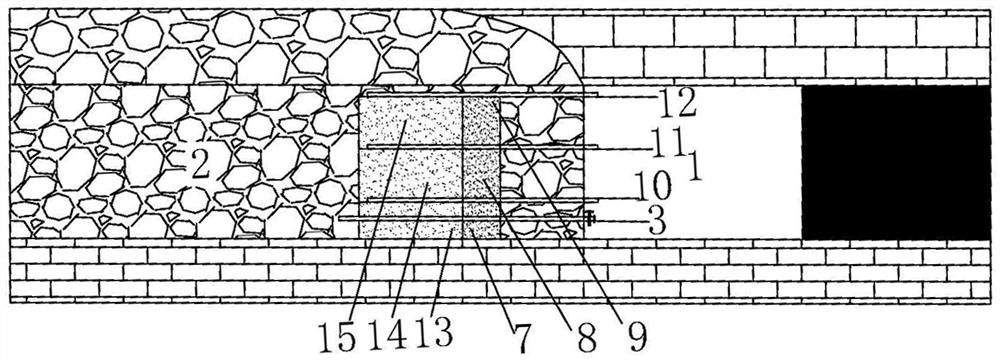

[0060]The average dip angle of the coal seam in a certain mine is 6°, the average dip angle of the strike is 4°, and the topography of the incision hole of the working face is low. Flint limestone with a thickness of 4.79m, buried depth of 450m, mining roadway is 2.5m high and 5.2m wide. Due to the overall use of non-coal mining, after the mining face caving method, a large area of the goaf will collect water, so that the mining of the lower section of the working face is continuously threatened by the water in the upper section of the goaf. The average water inflow on the gob side of the working face is 50m 3 / h, the average depth of accumulated water in the roadway within 200m from the cutout of the roadway under the working face is about 500mm, and the hydrostatic pressure is less than 0.1MPa. combine figure 1 , figure 2 , image 3 , Figure 4 As shown, a method for preventing and controlling water catchment in mined goaf without coal pillars is carried out accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com