Detachable nested composite superconducting cavity

A superconducting cavity and nested technology, which is applied in the field of radio frequency superconductivity, can solve difficult problems such as processing, and achieve the effects of reduced maintenance costs, reduced volume, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

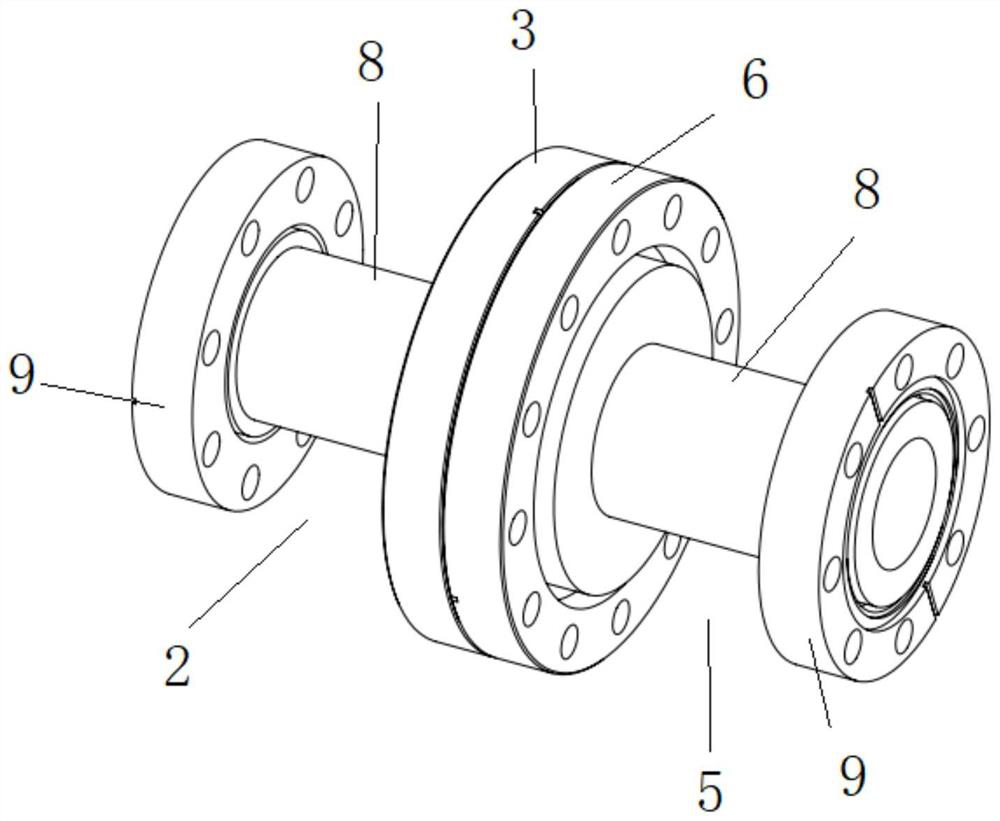

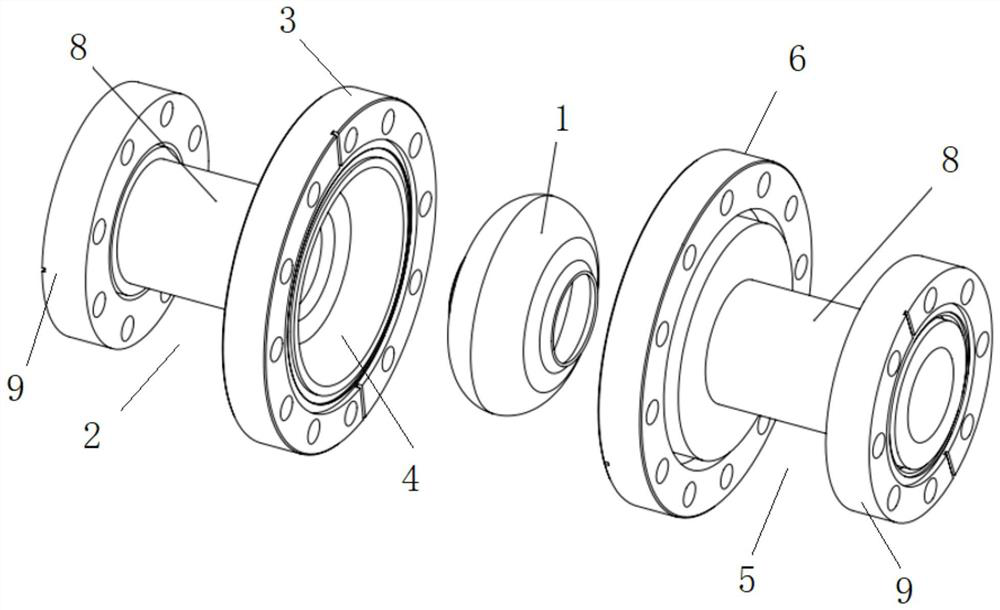

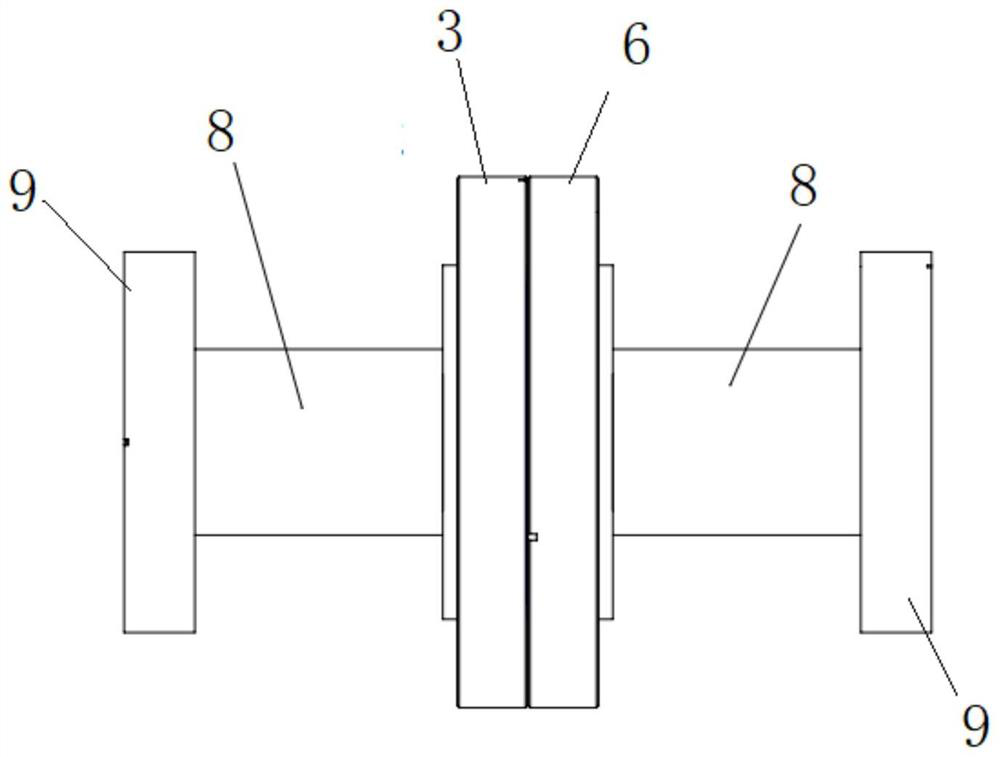

[0035] In this embodiment, a detachable nested composite superconducting cavity is provided. In this embodiment, as Figure 1 to Figure 7 shown, the nested composite superconducting cavity includes:

[0036] At least one superconducting inner cavity 1 is provided, and the superconducting inner cavity 1 is placed in a vacuum environment as a whole; since the superconducting inner cavity 1 is in a vacuum environment as a whole, its interior is a complete vacuum environment, and the outer wall is a vacuum environment, but it is in a vacuum environment. There is no atmospheric pressure difference between the inner and outer walls of the superconducting cavity 1.

[0037] The first non-superconducting shell 2 is provided with a first connection sealing flange 3 at one end, and a first semicircular groove 4 is provided on the inner side of the first connection sealing flange 3;

[0038] The second non-superconducting housing 5 is provided with a second connection sealing flange 6 ...

Embodiment 2

[0047] The disassembled nested composite superconducting cavity provided in this embodiment has basically the same structure as the disassembled nested composite superconducting cavity provided in Embodiment 1, the difference is that the superconducting cavity in this embodiment The number of inner cavities 1 is set to be two or more. In addition to the structure included in Embodiment 1, it also includes at least one double-headed housing 10, such as Figure 8 to Figure 11 shown.

[0048] The double-headed housing 10 is used as a connecting head, and both ends of the double-headed housing 10 are respectively provided with third connecting sealing flanges 11 , the inner side of the third connecting sealing flange 11 is provided with a third semicircular groove 12 , The grooves 12 are respectively matched with the first semicircular groove 4 and the second semicircular groove 7 to form sealed accommodating cavities respectively; each accommodating cavity is provided with a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com