Rice dumpling vacuum packaging technology and two-in-one novel bag feeding type vacuum packaging machine

A vacuum packaging machine and vacuum packaging technology, applied in the field of rice dumpling vacuum packaging technology, two-in-one new bag-feeding vacuum packaging machine, to achieve the effect of not being easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

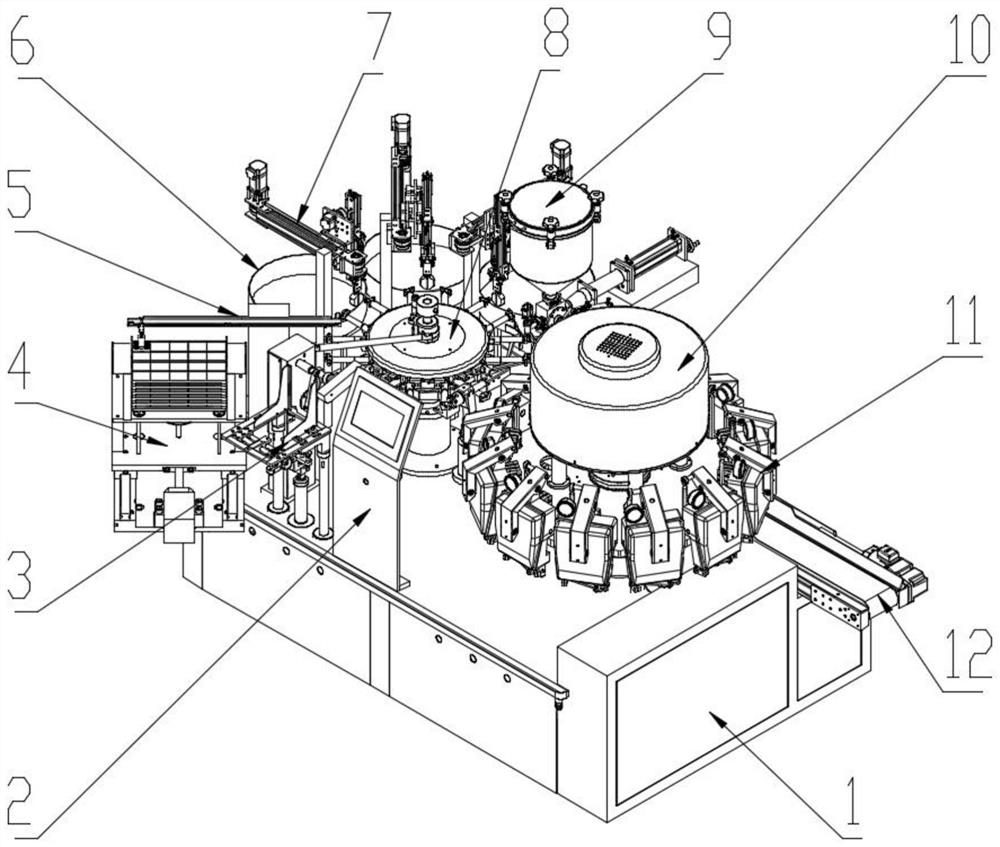

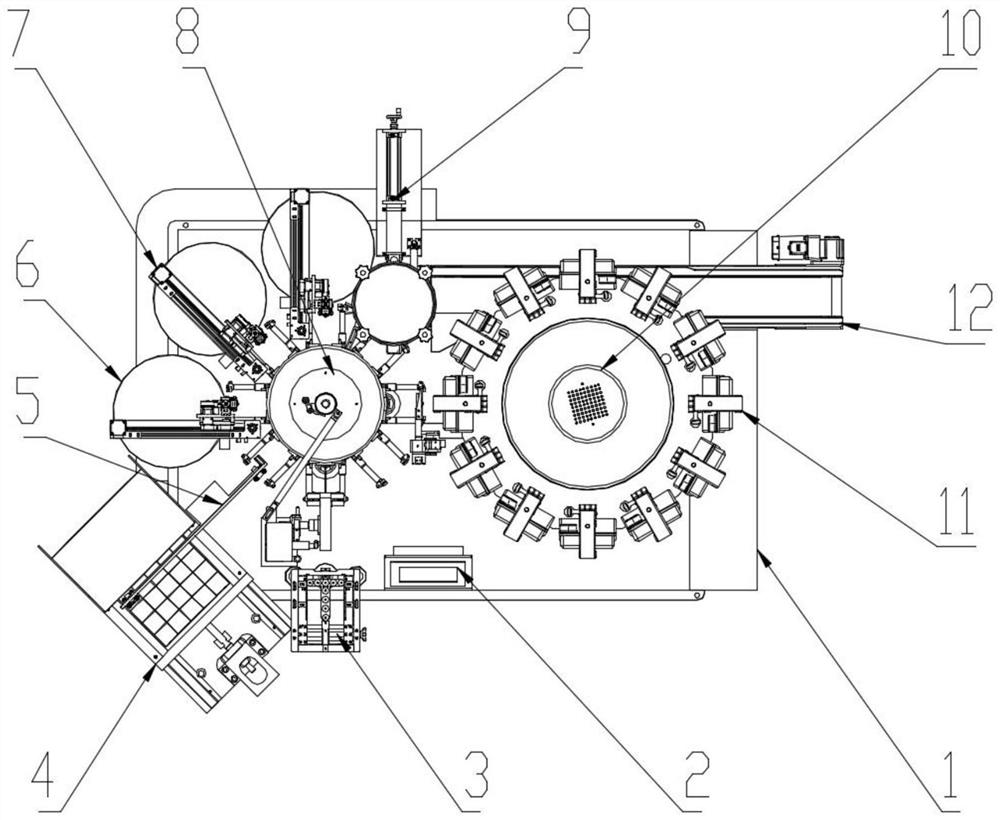

[0060] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

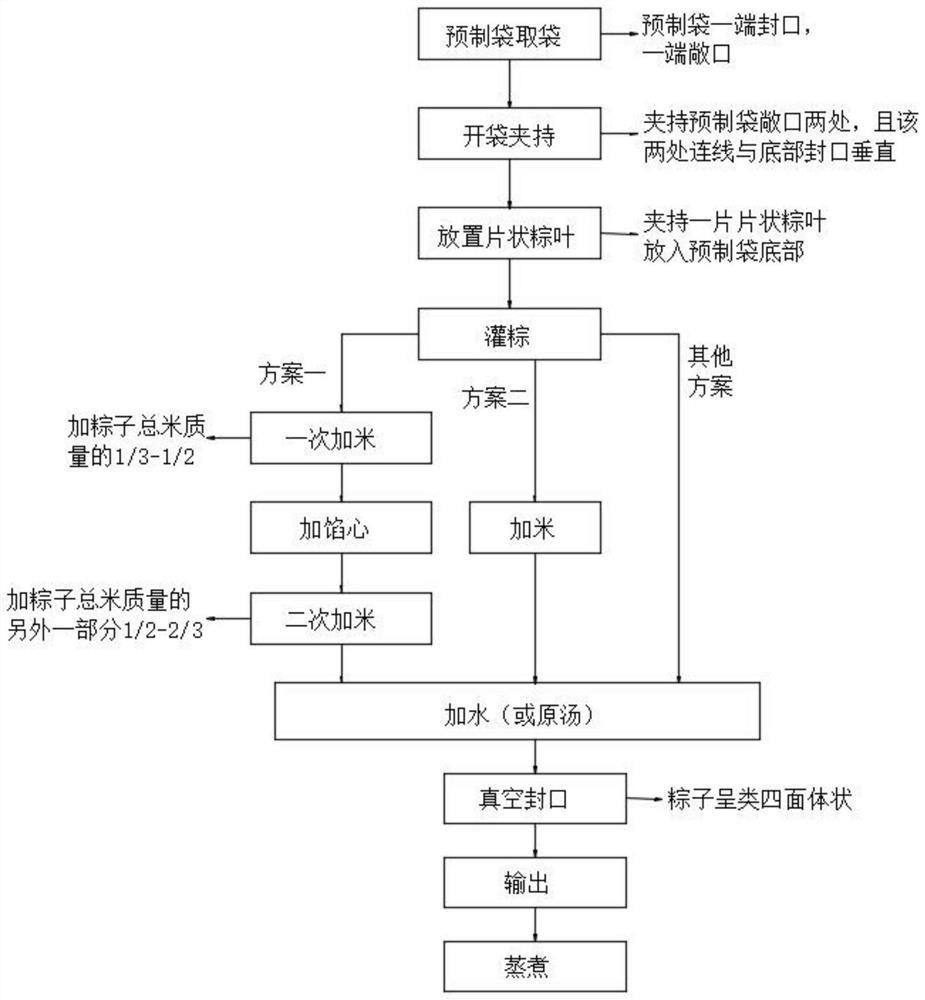

[0061] like figure 1 As shown, this rice dumpling vacuum packaging process, the steps are as follows:

[0062] Step 1, take down the prefabricated bag and open it, one end of the prefabricated bag is sealed, and the other end is open;

[0063] Step 2, clamp the open ends of the prefabricated bag at two places, and the connection line between the two places is perpendicular to the bottom seal;

[0064] Step 3: Hold a piece of zongzi leaf and place it into the bottom seal of the prefabricated bag;

[0065] Step 4, filling rice dumplings: S1, adding rice to the interior of the prefabricated bag once as required, (the rice that is quantitatively added is the rice after soaking and seasoning, and the amount of rice added is fixed), S2, adding filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com