Underwater high-irradiation-resistant mechanical arm joint structure

A technology of robotic arms and joints is applied in the field of underwater high-irradiation-resistant robotic arm joint structures, which can solve the problems of high-irradiation resistance and underwater sealing of multi-joint robotic arms, and achieve the effects of good sealing and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

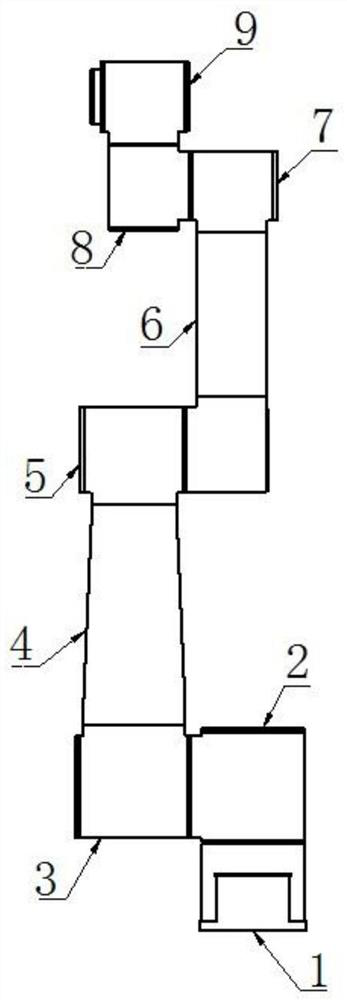

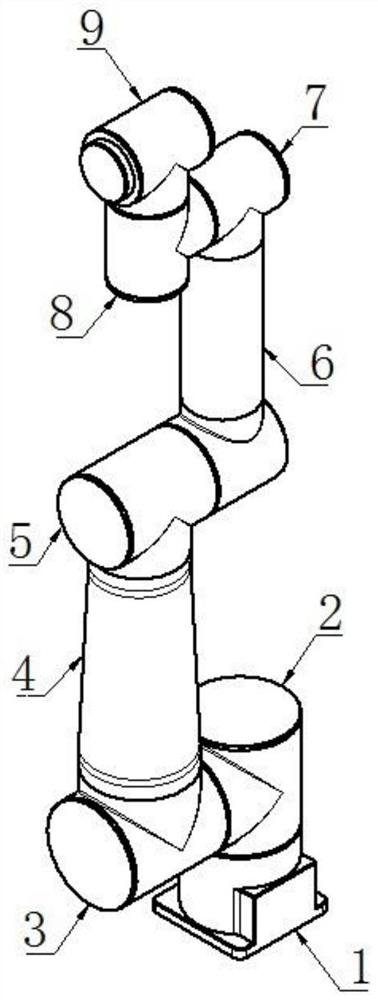

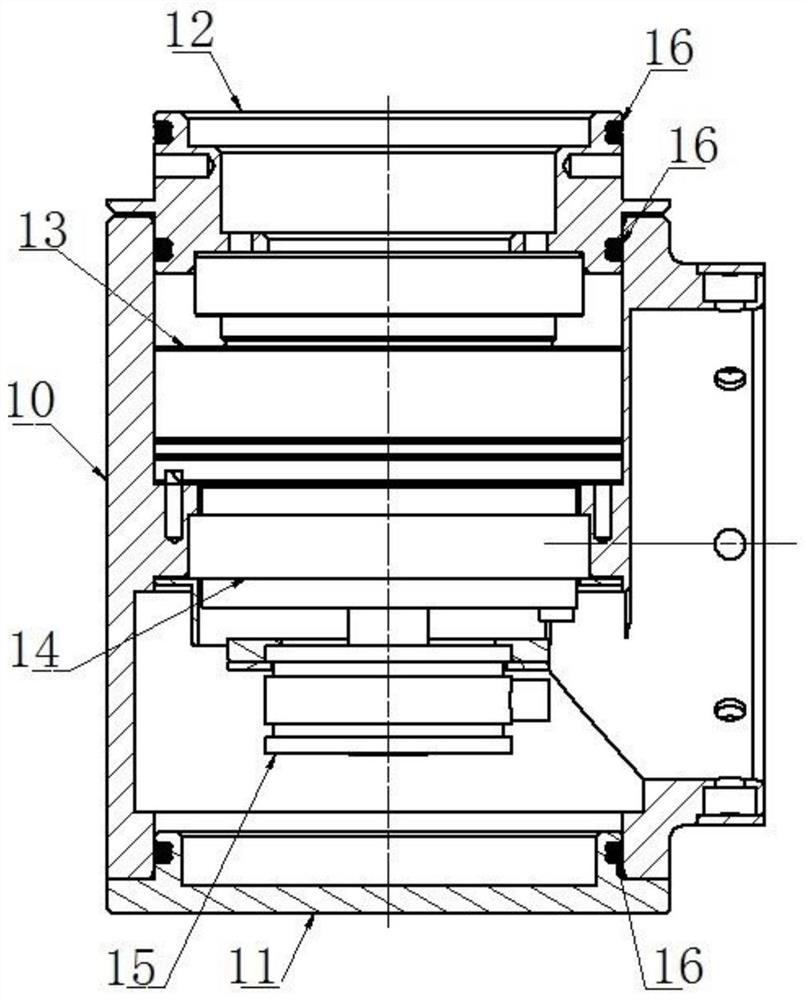

[0020] In the underwater high-irradiation-resistant manipulator structure provided by the present invention, compared with a general multi-joint manipulator, the joints of the manipulator adopt an irradiation-resistant design, which removes unnecessary sensors and replaces the sensors that must be retained with Radiation-resistant type, and rationalize the position of electronic components, so that the radiation-resistant requirements of the manipulator body can be met. At the same time, the joints of the robotic arm are designed to be waterproof, and a single joint can be sealed with only three sealing rings.

[0021] Compared with the general multi-joint manipulator, the present invention adopts the radiation-resistant design for the joints of the manipulator, removes unnecessary sensors, replaces the sensors that must be retained wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com