Crawler crane and deformation method thereof

A technology of crawler cranes and cranes, which is applied in the direction of cranes, ship accessories, passenger handling equipment, etc., can solve the problems of limited construction scope of super-large tonnage crawler cranes, increased purchase and use costs of crane users, and increased equipment idle rate, so as to increase the number of customers Profitability, conducive to production organization and management, and improve the effect of modularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

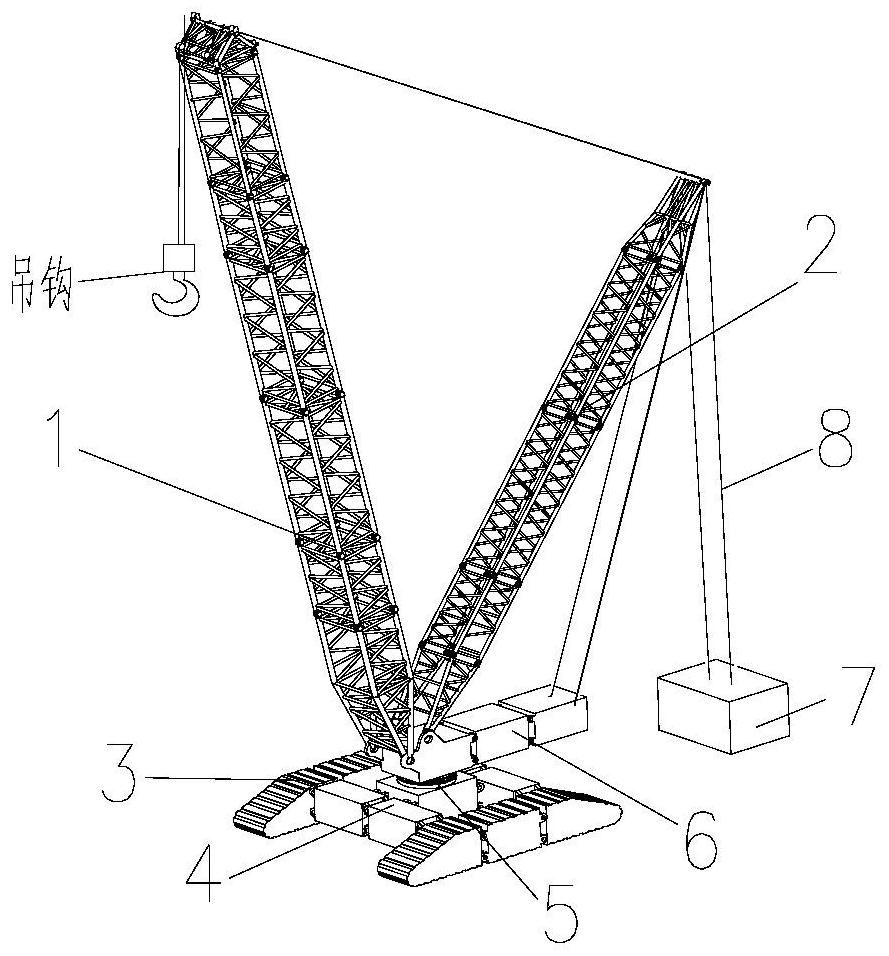

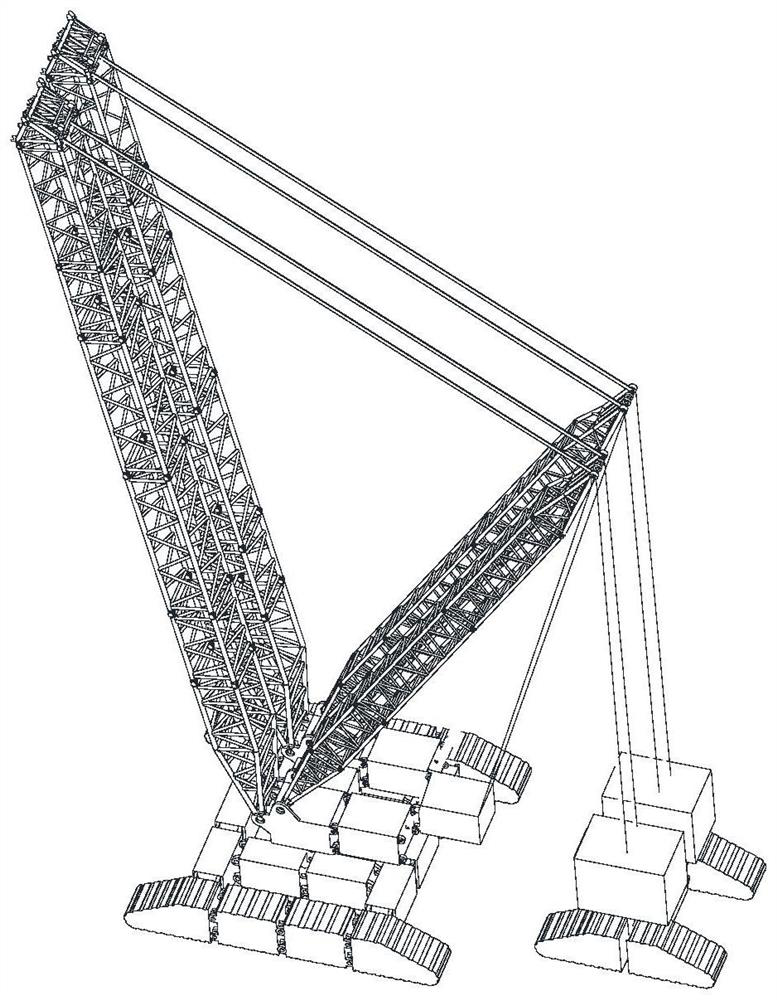

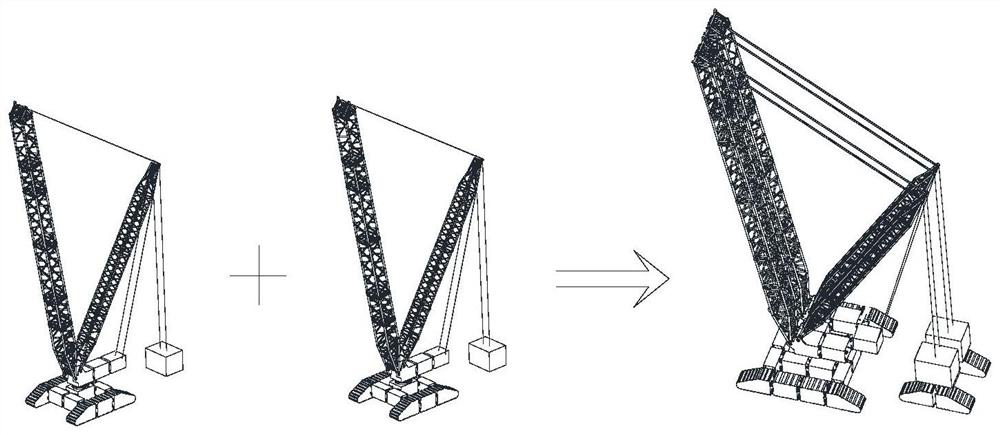

[0051] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0052] In order to improve the equipment utilization rate of crane users and reduce the procurement and operation cost of the innovative solution, the customer only needs to purchase two basic crawler cranes and some expansion parts, which can be transformed into larger crawler cranes. The larger crawler crane after deformation is used for hoisting. After the overweight parts are hoisted, they can be decomposed into two basic crawler cranes, so that both cranes are put into operation, which greatly improves the operation efficiency of the equipment. At the same time, the basic crawler crane occupies an area The area is small, the control is flexible, and it meets the requirements of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com