Intelligent duct piece for concrete embedded air/liquid inflation steel pipe

A concrete-in-concrete technology, applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of raising the project cost, increasing the dead weight of the structure, cumbersome construction process, etc. osmotic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

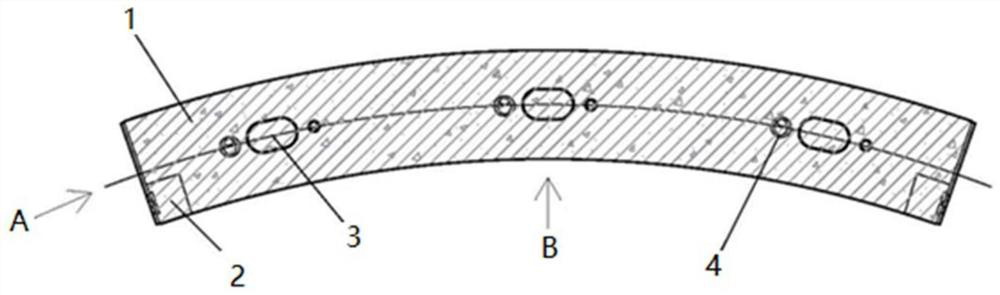

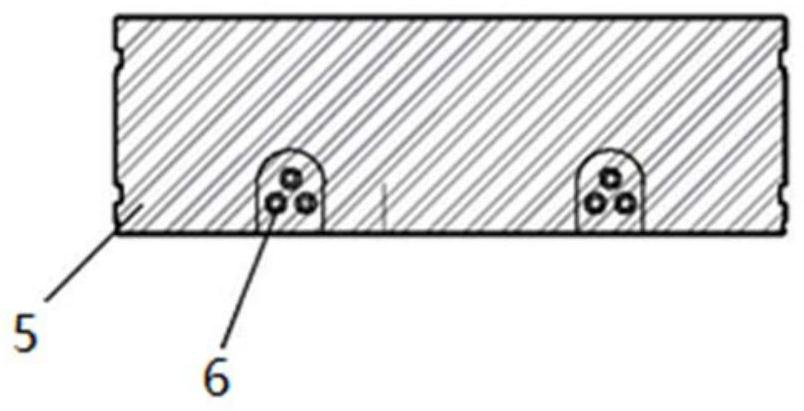

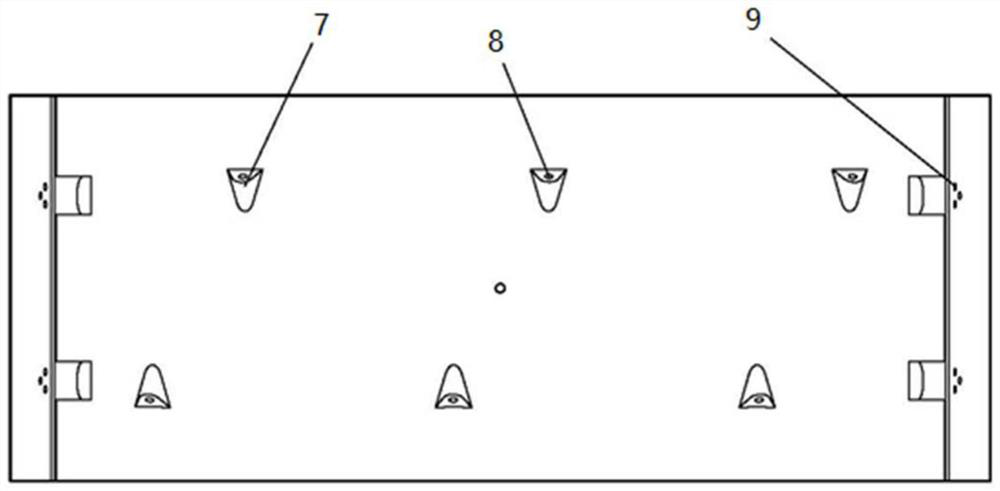

[0064] Taking a shield tunnel across the Yangtze River as an example, the inner diameter of the tunnel segment is 14.1m, the outer diameter is 15.4m, the wall thickness is 650mm, and the ring width is 2m. In the form of ultra-high performance concrete embedded inflatable steel pipe composite segment, four hollow steel pipes with a thickness of 8mm are arranged inside the segment. Among them, the middle two steel pipes have a diameter of 200mm and a center-to-center distance of 360mm, and the outer two steel pipes have a diameter of 100mm and a center-to-center distance of 1560mm. , and the inside of the steel pipe is filled with 3MPa high-pressure gas.

[0065] Through the numerical simulation of finite element software, it is found that compared with the existing concrete shield segments, the self-weight of the ultra-high performance concrete-embedded air-filled steel pipe composite segment is reduced by nearly 10%, while the stiffness is increased by nearly 30%, which effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com