Heat accumulator, air conditioner outdoor unit and air conditioner

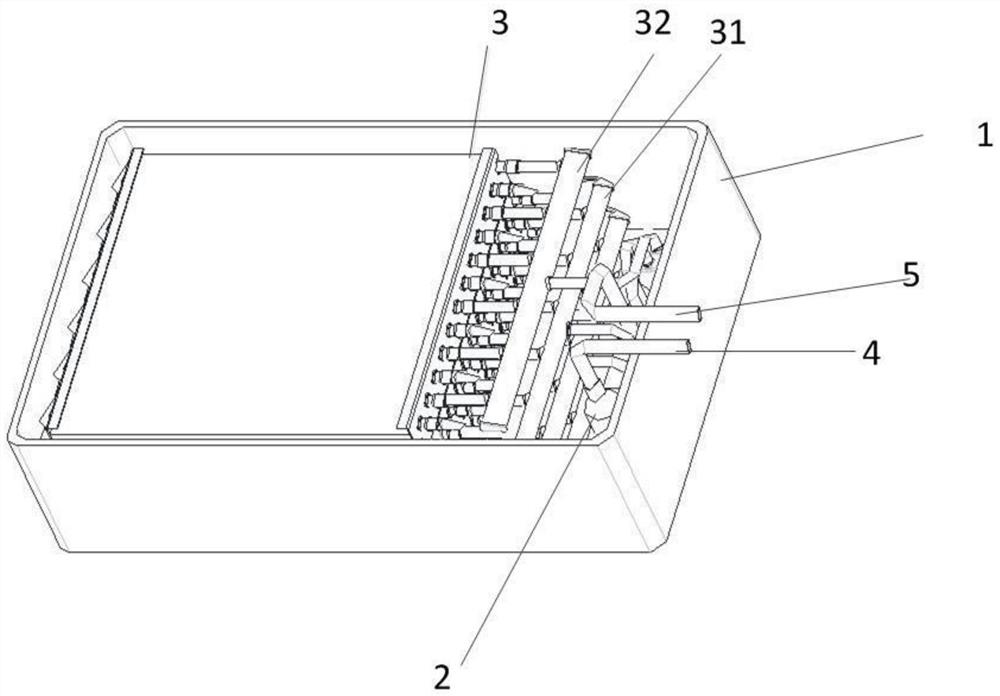

A technology for heat accumulators and heat exchangers, which is applied in air conditioning systems, heat storage equipment, indirect heat exchangers, etc. It can solve the problems of heat storage in heat accumulators, low heat release efficiency, long defrosting time of units, and insufficient liquid supply, etc. problems, to achieve the effect of spacious circulation space, increased contact area, and improved heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] At present, when the heat pump air conditioner operates for heating in winter, the air-side heat exchanger acts as an evaporator. Due to the low ambient temperature, the temperature of the surface of the heat exchanger also drops, even below 0°C. When the outdoor air flows through When the heat exchanger coils, the moisture contained in it will separate out and form a frost layer. The defrosting process of the heat exchanger needs to take heat from the indoor side, which makes the indoor temperature fluctuate greatly, and the indoor comfort becomes poor. In order to solve the problem of rapid defrosting and large indoor temperature fluctuation during defrosting, a phase change heat storage module can be used for defrosting.

[0051] At present, most of the heat exchangers in the heat storage device are composed of micro-channel flat tubes and fins arranged on the micro-channel flat tubes. However, this structural design has very uneven distribution of refrigerants, and ...

Embodiment 2

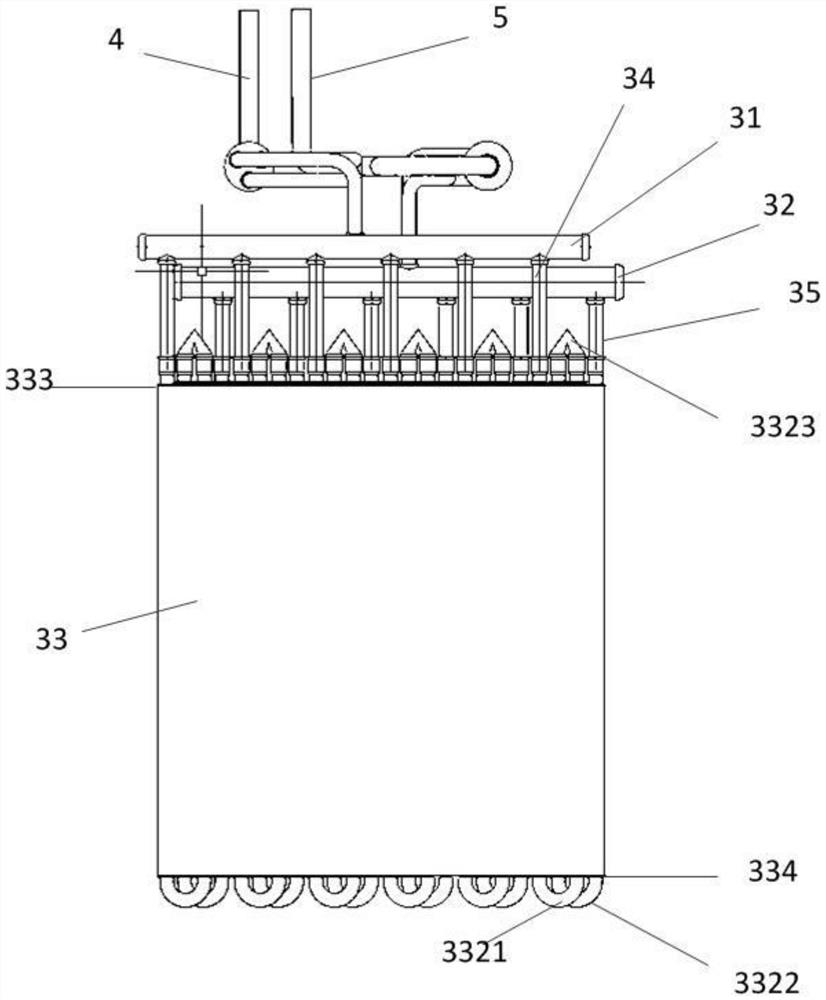

[0074] In the heat accumulator described in the above embodiment, the heat exchanger components of the heat accumulator can evenly distribute the refrigerant, and can avoid "too much liquid supply" and "insufficient liquid supply", and then the heat storage, Problems such as low heat release efficiency and long defrosting time of the unit. The heat pump air conditioners currently developed in the industry, in order to improve the heat storage capacity of the heat accumulators, need to increase the number of heat accumulators or increase the volume of the heat accumulators to meet the heat storage requirements, resulting in a waste of manufacturing costs and installation space. Although the existing industry technicians tend to miniaturize the overall size of the heat storage module in order to reduce the installation space Unreasonable, the heat exchange efficiency between the heat exchanger components and the phase change heat storage material is low, resulting in insufficien...

Embodiment 3

[0095] The above embodiment 2 implements a miniaturized invention design for the heat accumulator. In practical applications, for the practicability of the heat accumulator, the embodiment of the present application also implements a further invention design for the heat accumulator.

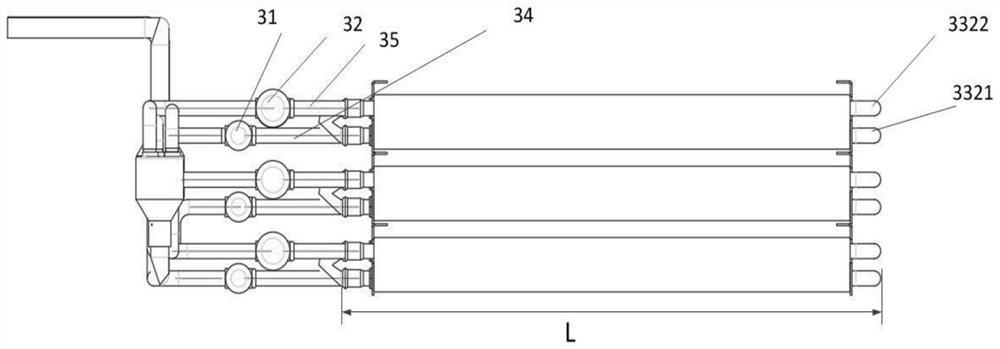

[0096] Figure 5 is a schematic structural diagram of the first tube sheet shown in the embodiment of the present application;

[0097] Figure 7 It is a schematic structural diagram of the second tube sheet shown in the embodiment of the present application.

[0098] see Figure 5 and Figure 7 .

[0099] The heat accumulator of the embodiment of the present application includes the structure of the first embodiment above, and the specific structural dimensions are set according to the second embodiment above and the actual application. The U tubes 332 are distributed parallel to the bottom surface of the shell 1; or the N heat exchange U tubes 332 are distributed parallel to the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com