Comprehensive evaluation method for bearing capacity of in-service hollow slab girder bridge

A technology of hollow slab beams and bearing capacity, which is applied in the directions of instruments, geometric CAD, and electrical digital data processing, etc., can solve problems such as improper consideration of the overall evaluation and failure to consider the work performance of the transverse force transmission structure between beams and slabs, and reduce the engineering cost. Accident probability, avoidance of incompleteness, effect of avoidance of force problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

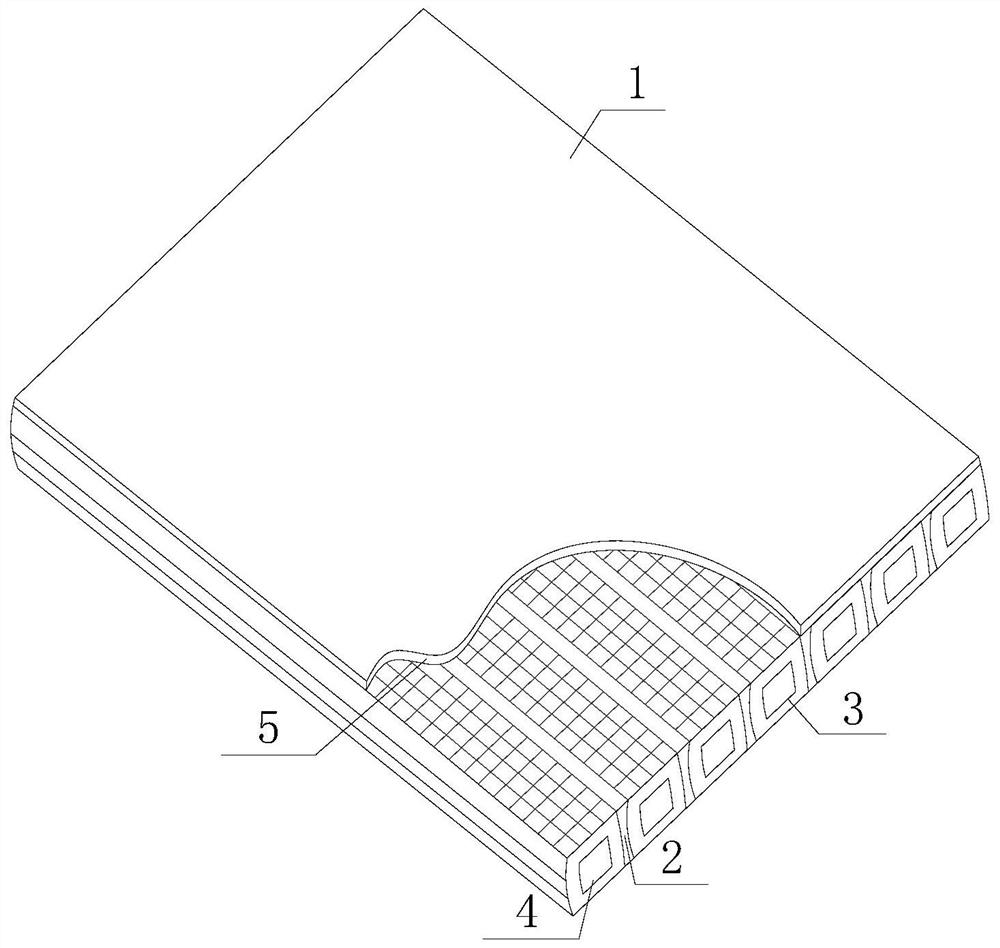

[0037] The present invention will be further described below in conjunction with the accompanying drawings. refer to Figure 1 to Figure 5 , a comprehensive assessment method for the bearing capacity of in-service hollow-slab girder bridges, including the following steps:

[0038] Step a, analysis data collection

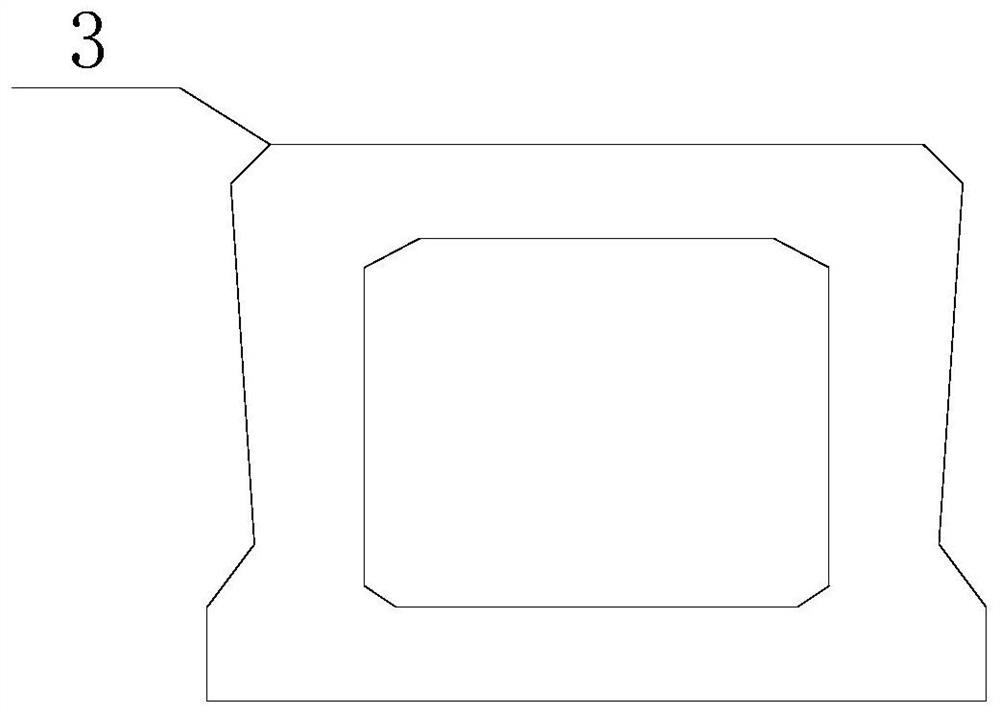

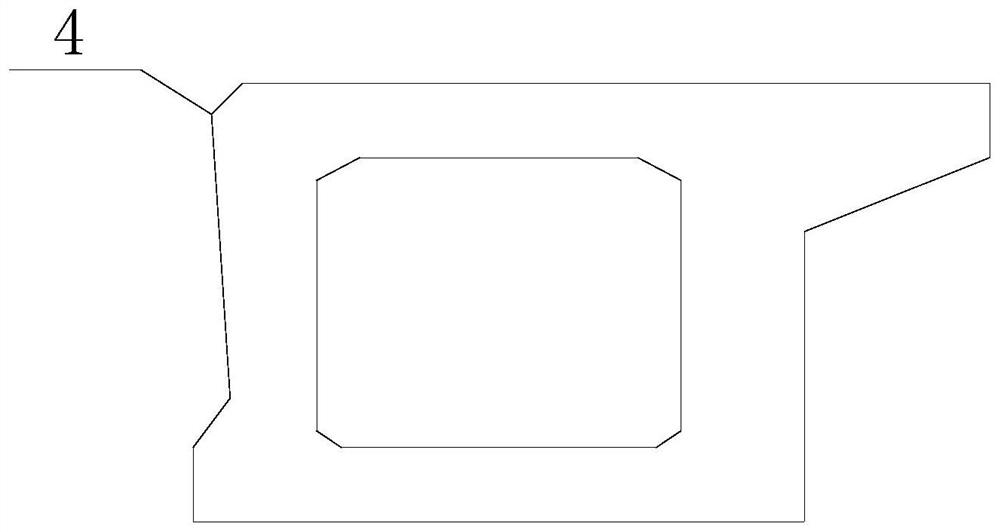

[0039] For hollow slab girder bridges (such as figure 1 ), design a test plan, and arrange test points on site (such as Figure 4 Deflection (displacement) measuring points (circles) in Figure 5 The strain measuring point (black point) in the test structure is tested and the strain and deflection of the structure are tested under the test load.

[0040] Test the following test data: Strain measurement value Si before loading 0 , the strain measurement value Sl when the loading reaches stability 0 , the measured strain value Su when it reaches stability after unloading 0 and the theoretical value of strain loading Ss 0 ; Measured value Si of deflection befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com