Finite element analysis-based large-scale equipment lifting lug design and optimization method

A large-scale equipment and optimization method technology, applied in the direction of design optimization/simulation, calculation, instruments, etc., can solve problems such as the inability to analyze the local stress change of the stress tube joint of the lifting lug, the inability to consider the influence of the attachment, and the inability to calculate the size of the lifting lug. Achieve the effects of improving design accuracy and efficiency, optimizing the size of lifting lugs, saving materials and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

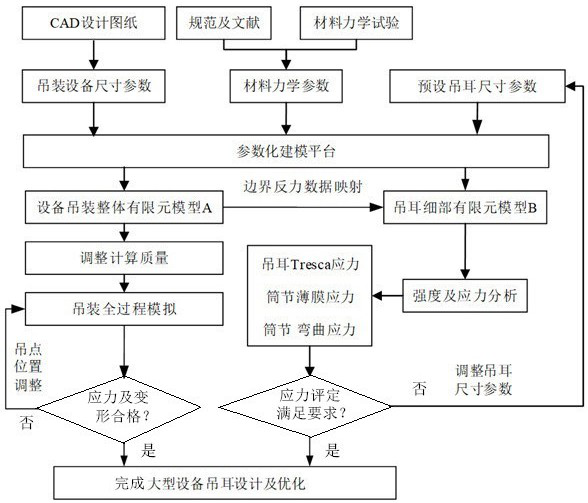

[0045] The method for optimizing the design of the lifting lug of large-scale equipment based on finite element analysis according to the present invention is as follows: figure 1 shown, including the following steps:

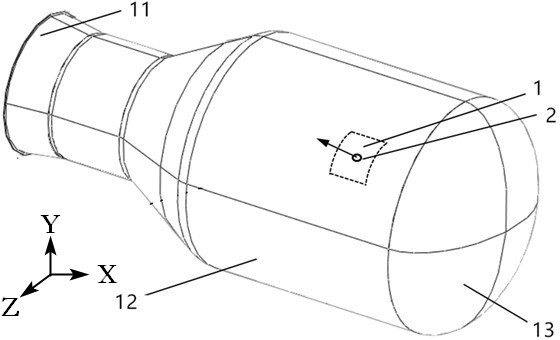

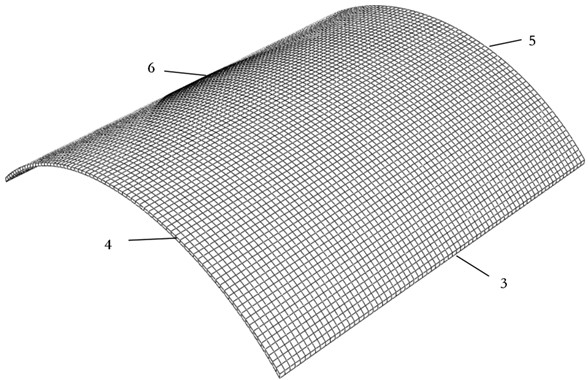

[0046] Step 1: Obtain size parameter information according to the CAD design drawing of the equipment. The size parameter information in this embodiment includes the size of the head 11 of the equipment, the nominal diameter, the thickness, the nominal diameter and thickness of the cylinder section 12, and the size of the skirt 13; according to the specification document And the material mechanical parameters of the equipment obtained from the material mechanical test, the material mechanical parameters include elastic modulus, Poisson's ratio, yield strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com