Plasma density control system and method

A plasma and density control technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as reducing production costs and uneven etching, and achieve the effect of reducing production costs and solving uneven etching problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1 The Faraday cup mounting frame is a straight bar frame

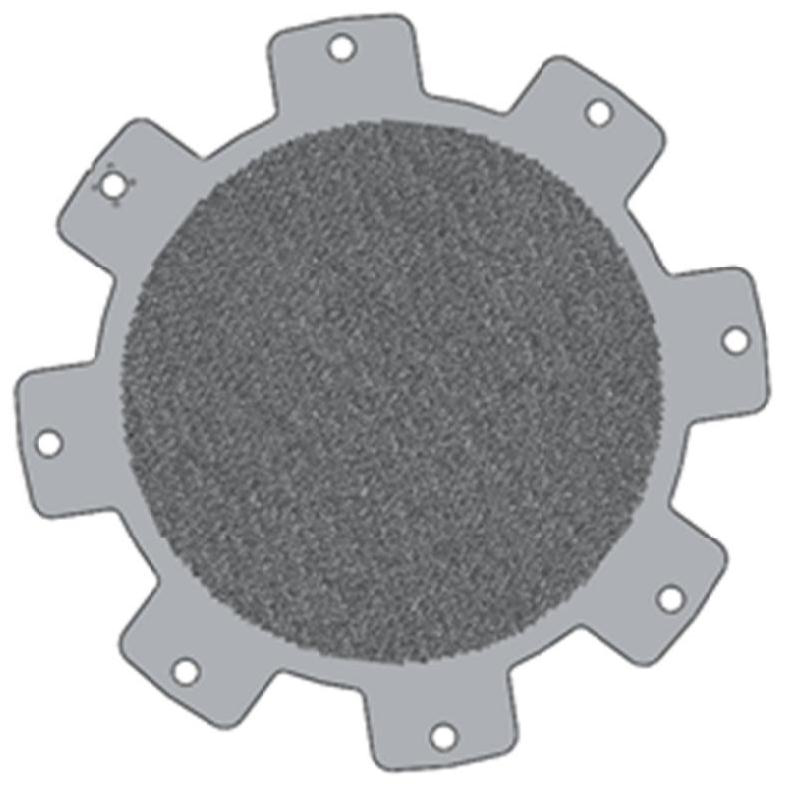

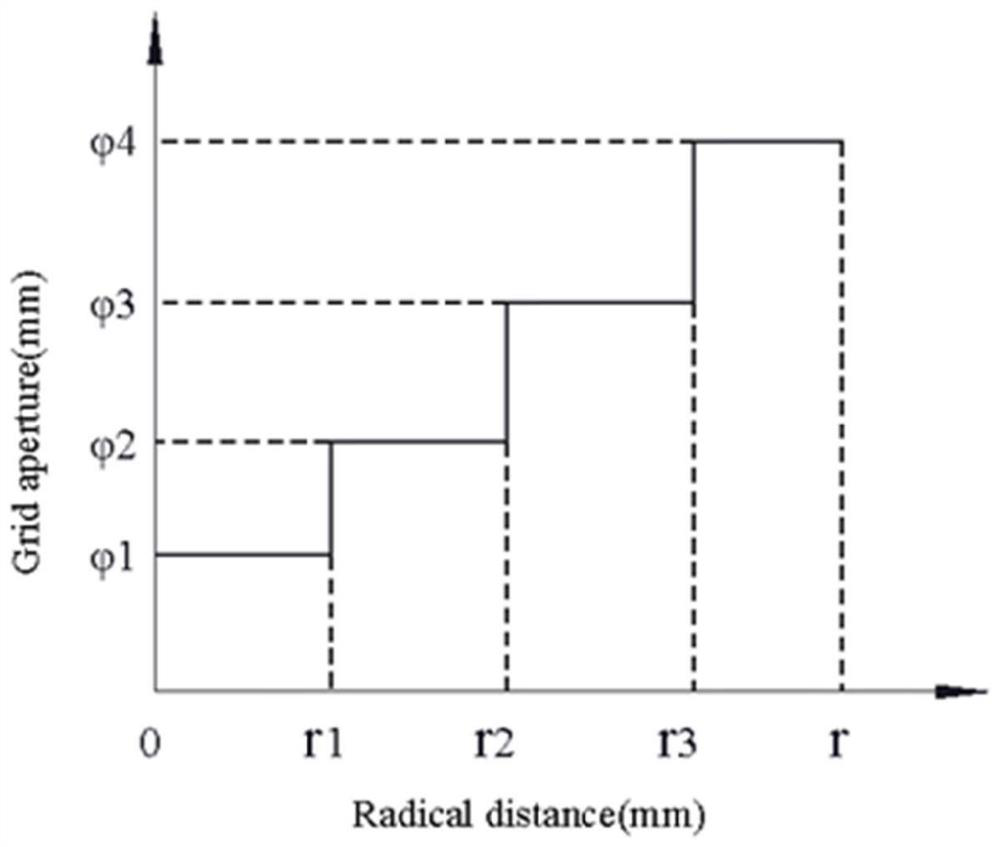

[0075] The Faraday cup mounting rack is a straight rack, and the number of Faraday cups is N+1. In this embodiment, since there are six groups of annular holes in the screen grid, that is, N=6, the number of Faraday cups is seven, such as Figure 8 As shown, from the center to the outside are Faraday Cup 1, Faraday Cup 2, Faraday Cup 3, Faraday Cup 4, Faraday Cup 5, Faraday Cup 6 and Faraday Cup 7.

[0076] One of the Faraday cups (that is, Faraday cup 1) is located on the central axis of the reaction chamber, and the remaining N Faraday cups are collinearly installed on the straight rack and correspond to the positions of the N screen grid annular holes.

[0077] That is, Faraday cup 2, Faraday cup 3, Faraday cup 4, Faraday cup 5, Faraday cup 6 and Faraday cup 7 are respectively 2.35mm, 2.47mm, 2.63mm, 2.72mm, 2.91mm and 3.13mm screen grid annular holes Accordingly, it is ensured that the plasma densi...

Embodiment 2

[0079] like Figure 9 As shown, the Faraday cup mount has an L-shaped frame (which can be a cross) with the corners of the L-shaped frame located on the central axis of the reaction chamber. The number of Faraday cups is preferably 2N+1.

[0080] One of the Faraday cups (that is, Faraday cup 1) is installed on the corner of the L-shaped frame, and N Faraday cups are installed on each of the two right-angled sides of the L-shaped frame.

[0081] The N Faraday cups on one of the right-angled sides are Faraday Cup 2, Faraday Cup 3, Faraday Cup 4, Faraday Cup 5, Faraday Cup 6, and Faraday Cup 7.

[0082] The N Faraday cups on the other right-angled side are Faraday cup 8, Faraday cup 9, Faraday cup 10, Faraday cup 11, Faraday cup 12, and Faraday cup 13.

[0083] 2N Faraday cups are located at different radial positions of the screen grid, and are respectively corresponding to the positions of the N screen grid annular holes. That is, Faraday cup 2 and Faraday cup 8 correspond t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com