Battery cell structure easy to unwind

A cell and winding core technology, applied in the field of cell structure that is easy to unwind, can solve the problems that the cell cannot be fixed, it is difficult to realize mechanized rewinding, and the efficient automatic recycling of power batteries is difficult, so as to achieve strong promotion value and improve recycling. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

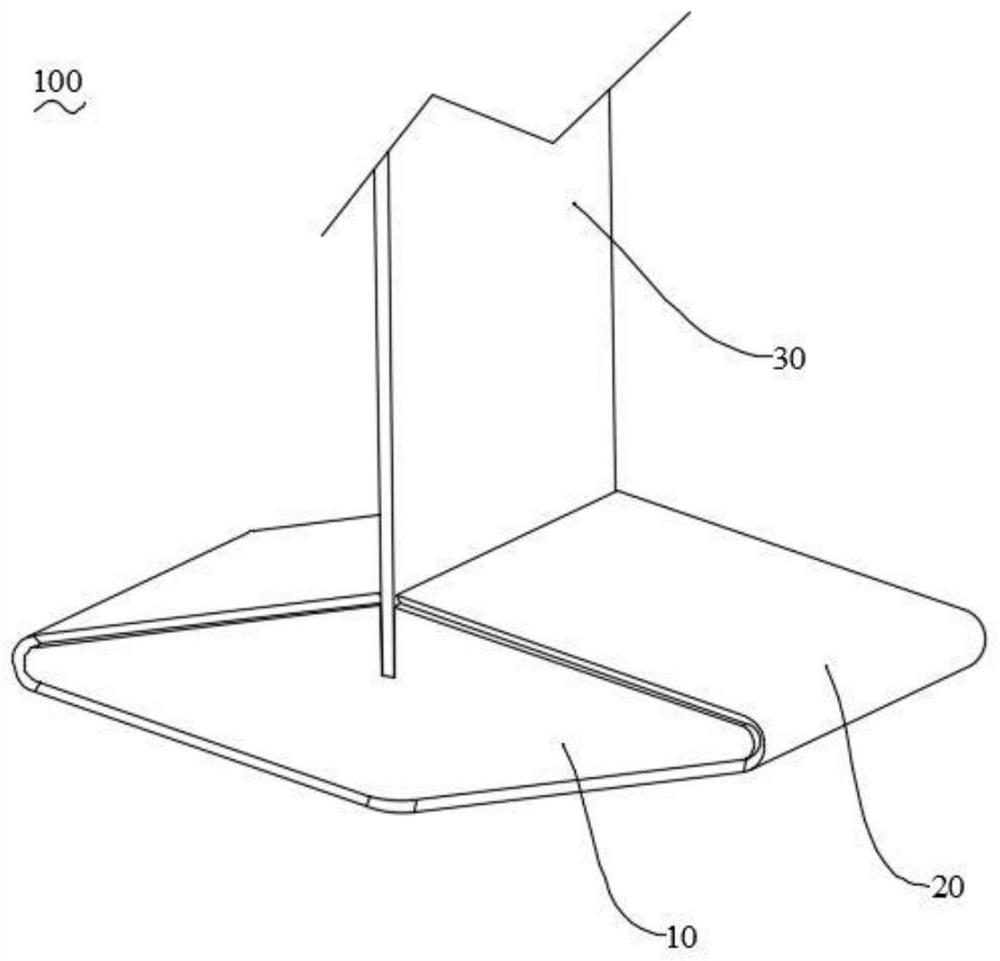

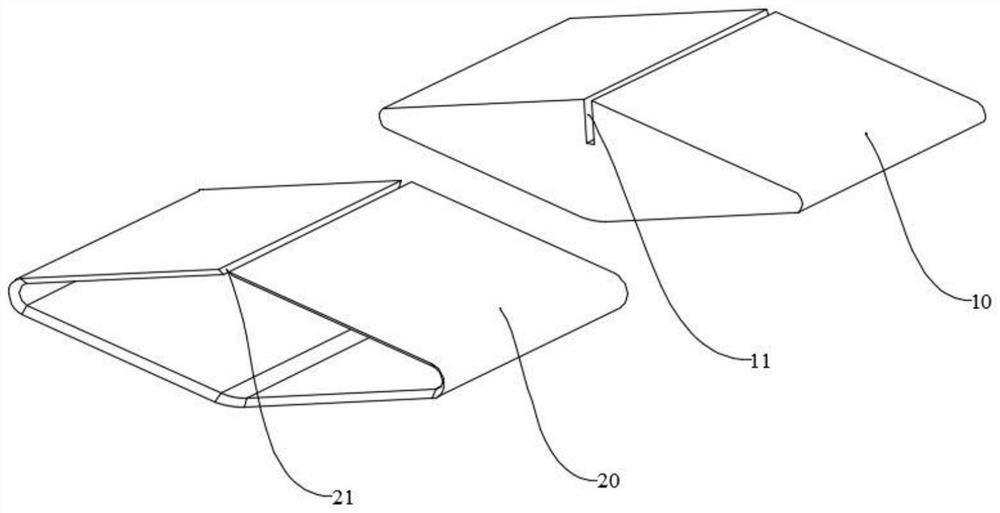

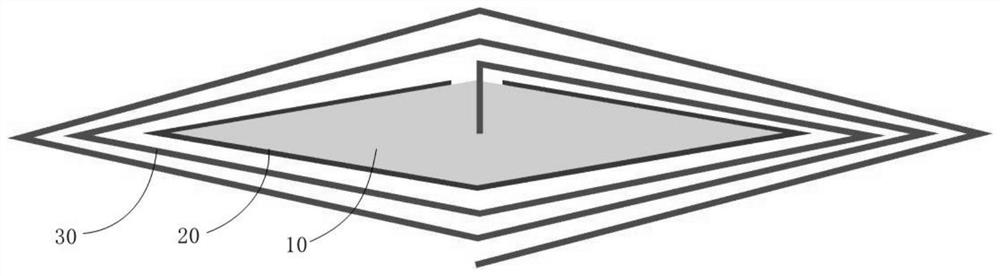

[0031] like Figure 1 to Figure 2 As shown, an easy-to-unwind cell structure 100 includes a winding core 10 and a bushing 20 sleeved on the outer peripheral wall of the winding core 10 . The cross-section of the winding core 10 is arranged in a diamond-shaped structure, and the shape of the bushing 20 is adapted to the shape of the winding core 10 to ensure that the inner peripheral wall of the bushing 20 is in close contact with the outer peripheral wall of the winding core 10 to ensure The shape of the winding body of the battery cells 30 formed after the battery cells 30 are wound on the bushing 20 does not change.

[0032] In this way, by covering the outer peripheral wall of the winding core 10 with the bushing 20 immediately adjacent to it, the bushing 20 not only serves as a carrier for the battery cells 30 during winding, but also guides the battery cells 30 during recovery. The rewinding core 40 is quickly inserted into the inner cavity of the bushing 20 , so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com