Method for holding part blank by fluid expansion in additive manufactured holding portion

A manufacturing method, additive manufacturing technology, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve problems such as mechanical stress troubles, low mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

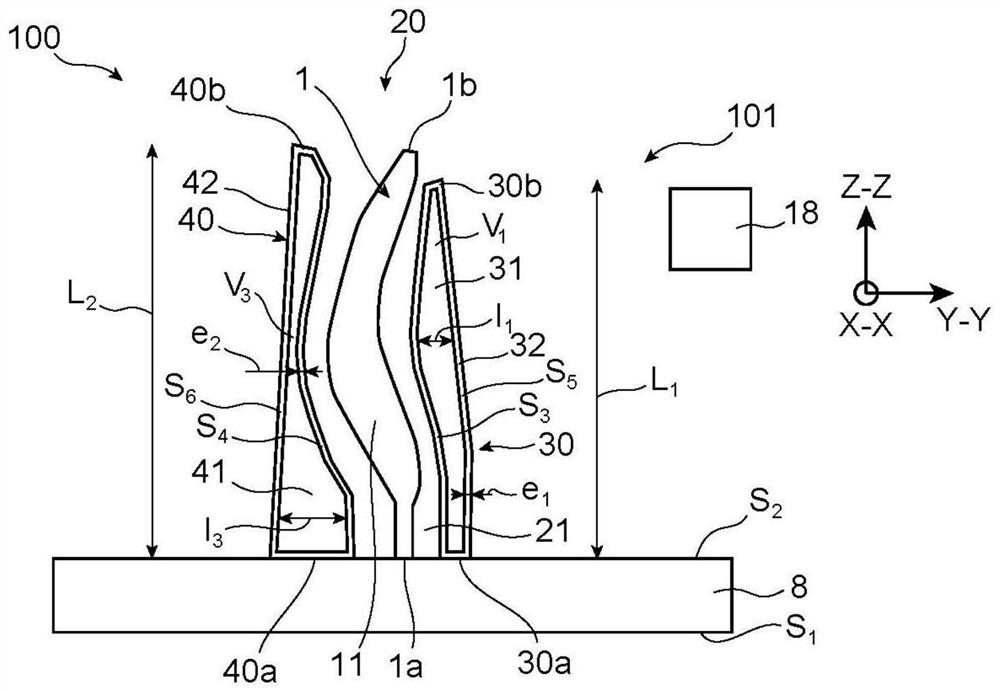

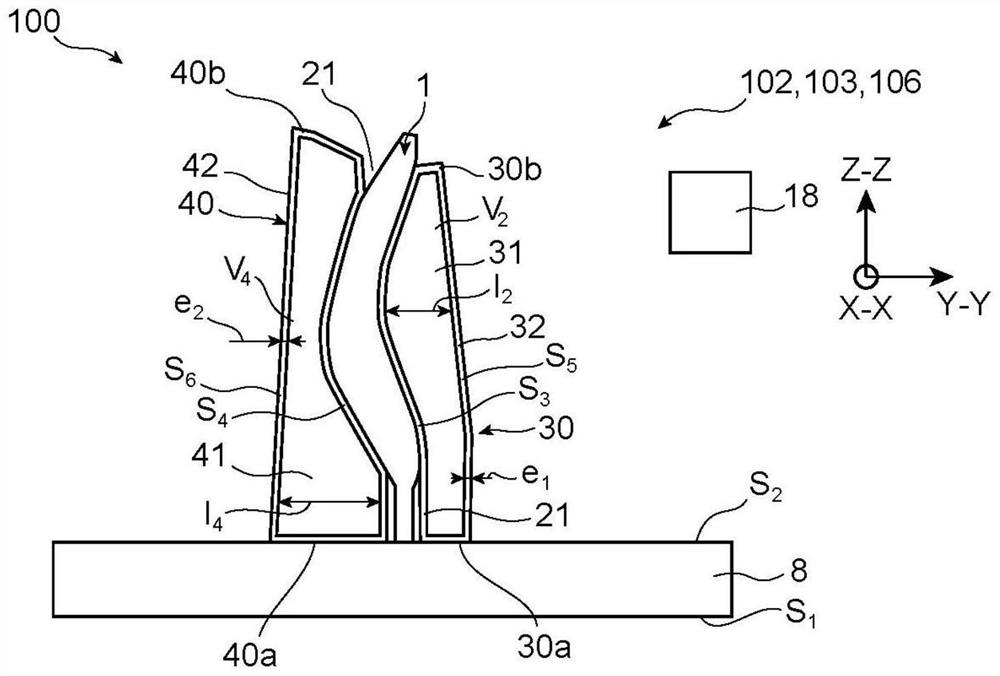

[0037] Identical, similar or equivalent parts in different figures have the same reference numerals to facilitate transition from one figure to another.

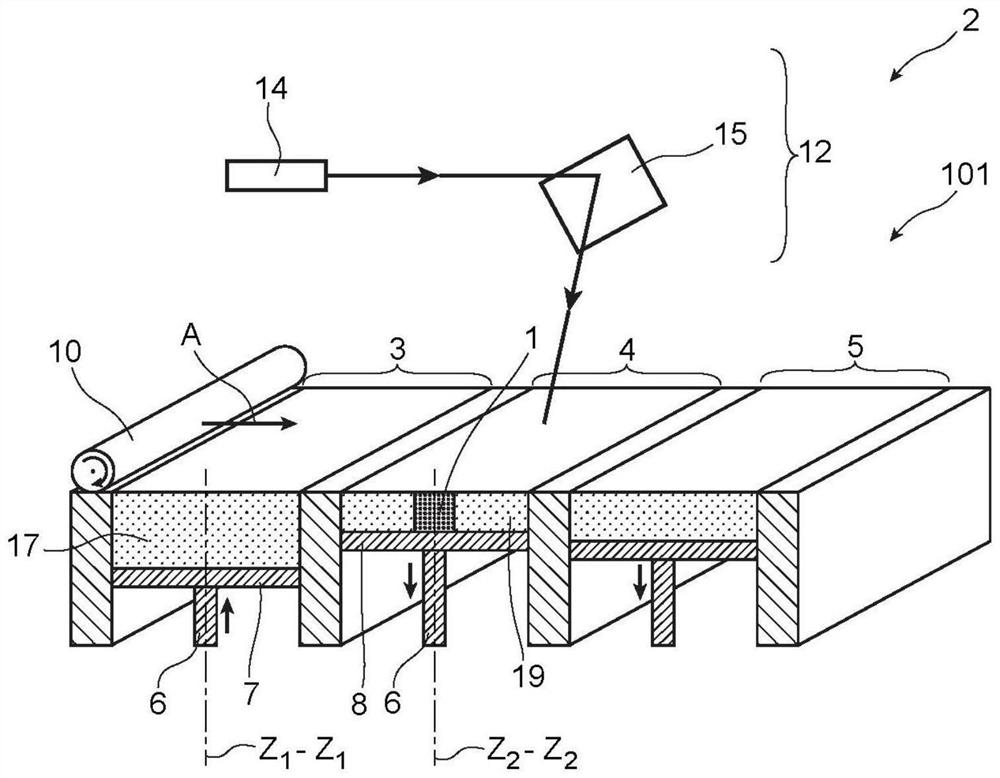

[0038] figure 1 An example of a tool 2 for manufacturing a component 1 by selective melting or selective sintering of a powder bed according to the manufacturing method of the first embodiment is shown.

[0039] Component 1 is an aircraft turbine engine component such as a blade, wall or flange. It in particular comprises at least one thin wall, which makes it relatively fragile. Nonetheless, it is designed to withstand particularly significant mechanical and / or thermal stresses during turbine engine operation. By additive manufacturing, it is manufactured from powder material 17, typically metallic material powder for aerospace applications.

[0040] The component 1 comprises a lower end 1a, an upper end 1b opposite the lower end 1a, and a body 11 between the lower end 1a and the upper end 1b. For example, it is not com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com