3D printer, artificial neuron and preparation method of artificial neuron

A 3D printer, neuron technology, applied in additive processing, medical science, prosthesis, etc., can solve the problems of unpreparable structure, external environment interference, difficult packaging, etc., to break through the complexity of product structure and improve environmental tolerance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

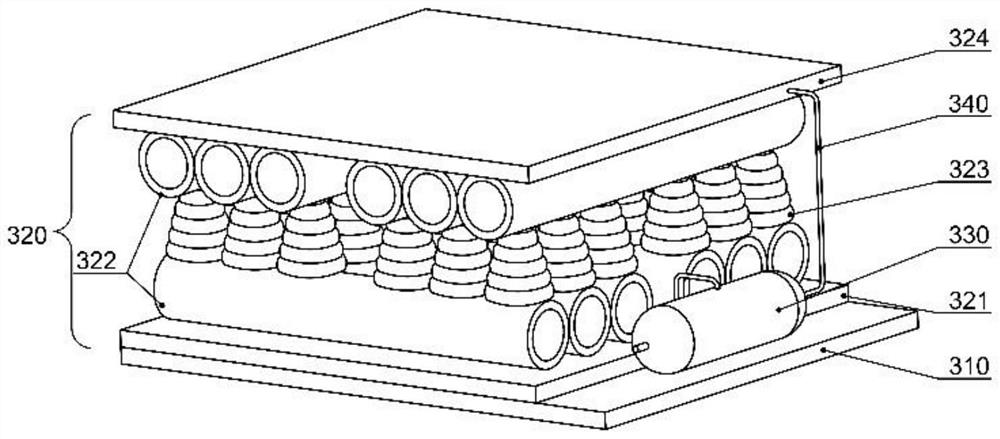

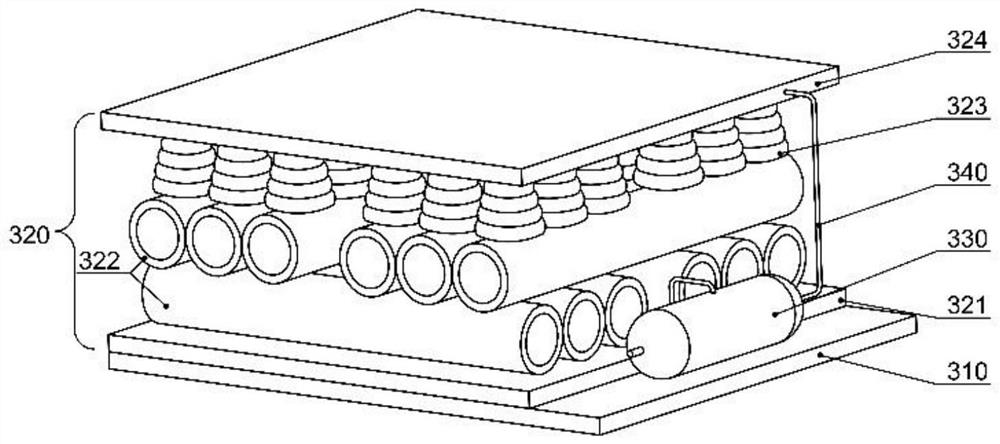

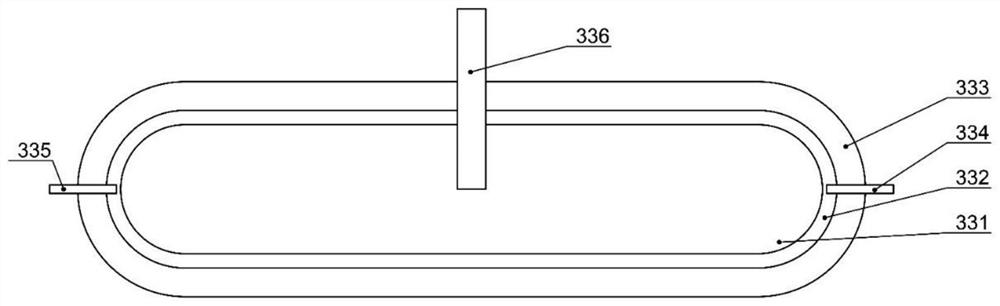

Image

Examples

Embodiment 1

[0076] This embodiment provides a method for preparing an artificial neuron with a tactile perception learning function using the above-mentioned 3D printer, including the following steps:

[0077] (1) After mixing PDMS SYLGARD 184 component A and component B in a ratio of 10:1, fully stir to prepare a slurry for printing the substrate and the encapsulation layer.

[0078] (2) Load the substrate printing paste prepared in step (1) into the barrel, move the ordinary nozzle 103 with a nozzle diameter of 200 μm to the forming position, switch the solenoid valve 131 through the first high-pressure gas pipe 132 to extrude the air pressure When it is 400kPa, the PDMS in the first barrel 123 is extruded, and two substrate layers are printed, and the thickness of the printed layer is 100 μm. After the printing of the substrate layer is completed, the temperature of the forming substrate is raised to 120°C, and the substrate is cooled after the substrate is solidified.

[0079] (3) The ...

Embodiment 2

[0089] (1) After mixing the PDMS SE 1700 A component and the B component in a ratio of 10:1, fully stir to prepare a slurry for printing the substrate and the encapsulation layer.

[0090] (2) Load the substrate printing paste prepared in step (1) into the barrel, move the ordinary nozzle 103 with a nozzle diameter of 400 μm to the forming position, and then switch the solenoid valve 131 through the first high-pressure gas pipe 132 to extrude the air pressure When the value is 500 kPa, the PDMS in the first barrel 123 is extruded to print one substrate layer with a thickness of 300 μm. After the printing of the substrate layer is completed, the temperature of the forming substrate is raised to 120°C, and the substrate is cooled after the substrate is solidified.

[0091] (3) The carbon nanotubes were added to a 0.1 wt % aqueous solution of cetyltrimethylammonium bromide at a ratio of 0.5 mg / mL, and sonicated for 120 min. The dispersed carbon nanotube slurry and PDMS were adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com