Pre-crushing device facilitating combustion of coal briquettes of industrial boiler

An industrial boiler and pre-crushing technology, applied in the cleaning method using tools, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve the problems of poor crushing effect, easy sticking of a large amount of coal dust, and broken nails. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

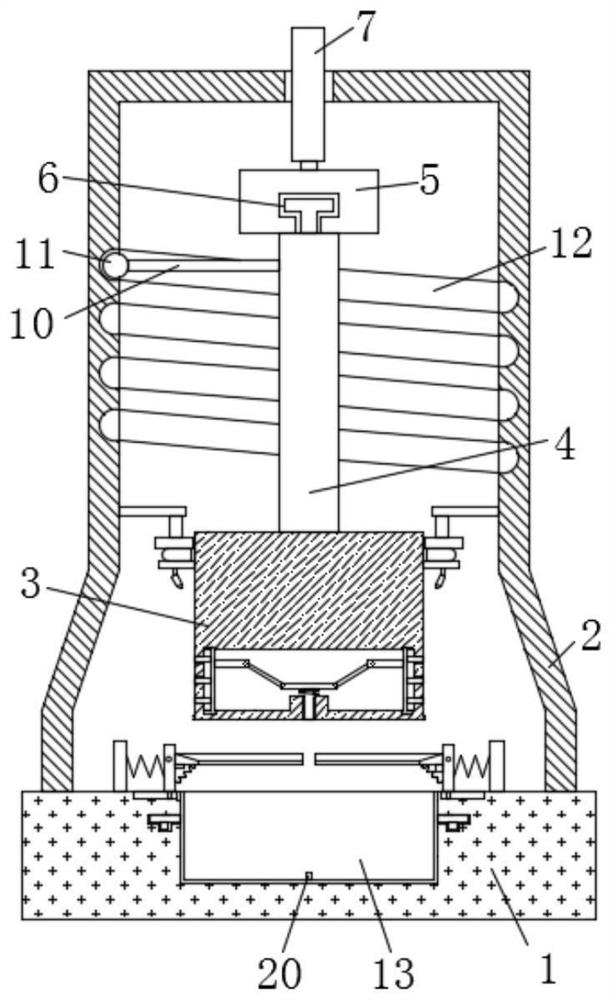

[0027] Example 1: refer to Figure 1-Figure 10 , a pre-crushing device that facilitates the combustion of coal lumps in an industrial boiler, comprising a support base 1, a fixed shell 2 is fixedly installed on the upper end of the support base 1, a broken hammer 3 is arranged on the inner and lower sides of the fixed shell 2, and the middle of the upper end of the broken hammer 3 is fixed A fixed column 4 is connected, the upper end of the fixed column 4 is provided with a fixed seat 5, the lower end of the fixed seat 5 is provided with a turning slot 6 corresponding to the fixed column 4, the fixed column 4 is rotatably connected to the fixed seat 5, and the upper end of the fixed seat 5 is fixedly connected with a The hydraulic cylinder 7, the hydraulic cylinder 7 penetrates the upper end of the fixed shell 2, and the hydraulic cylinder 7 is fixedly connected with the fixed shell 2, the upper side of the left end of the fixed column 4 is fixedly connected with a connecting r...

Embodiment 2

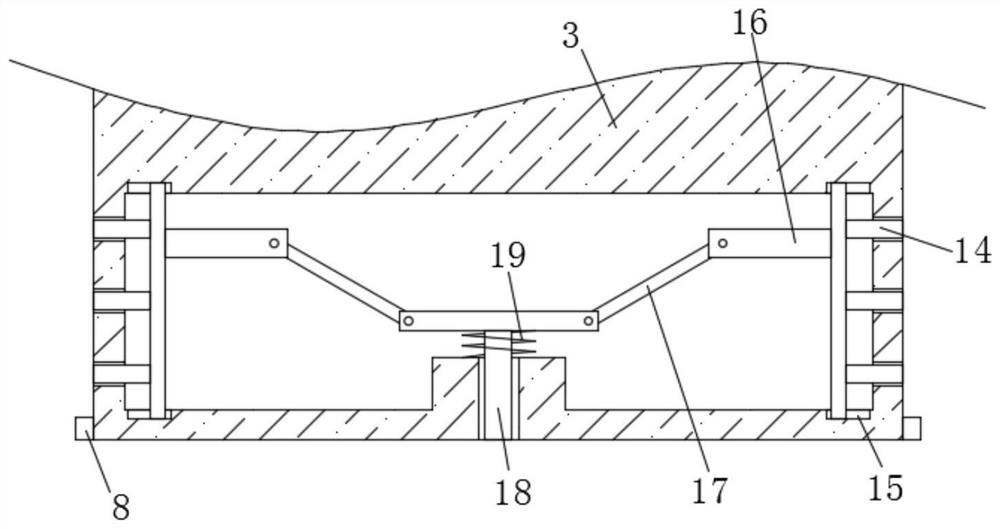

[0028] Embodiment 2: refer to Figure 1-Figure 10, In this embodiment, it is basically the same as the first embodiment, and the more optimal thing is that there are several crushing nail plates 14 on the outside of the breaking hammer 3, and a chute 15 is provided inside the breaking hammer 3 corresponding to the crushing nail plate 14. , the crushing nail plate 14 is slidably connected to the inside of the crushing hammer 3, the end of the crushing nail plate 14 close to the middle of the crushing hammer 3 is fixedly installed with the connecting rod two 16, and the end of the connecting rod 2 16 close to the middle of the breaking hammer 3 is hinged with the connecting rod three 17, One end of the connecting rod 3 17 close to the middle of the breaker 3 is hinged with a movable rod 18, the movable rod 18 runs through the lower end of the breaking hammer 3 and is connected to the lower end of the breaking hammer 3, and a top block 20 is fixedly installed in the middle of the ...

Embodiment 3

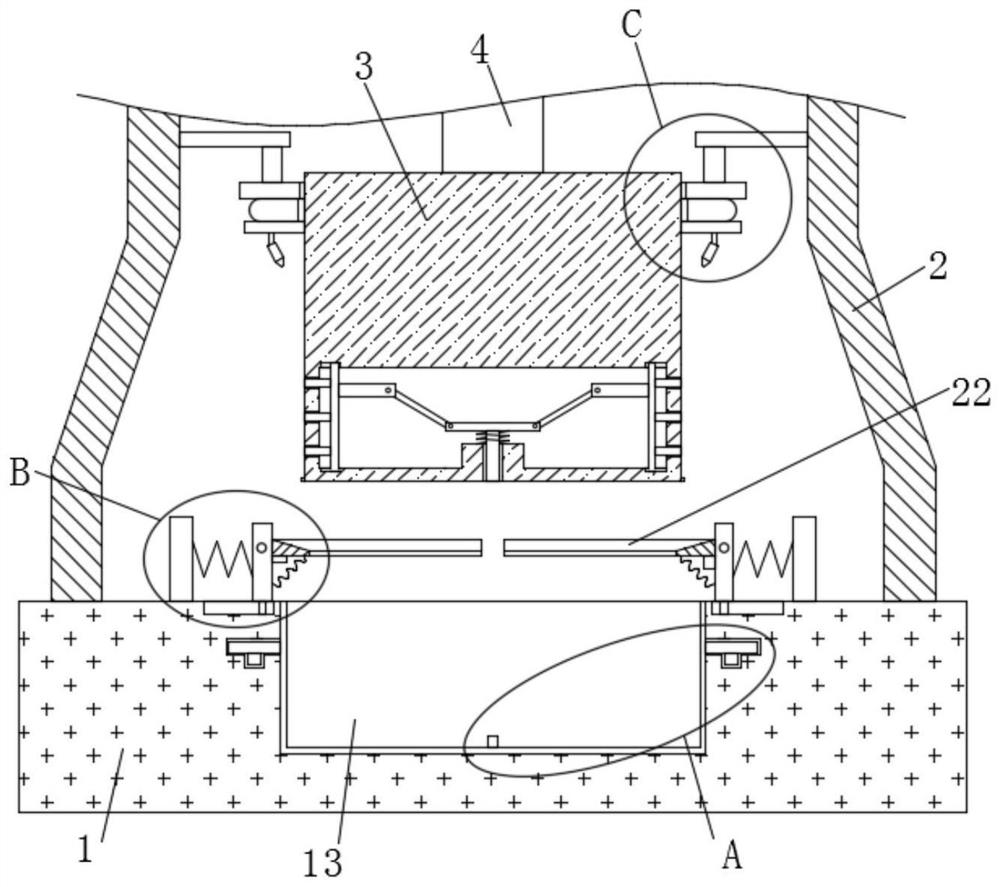

[0029] Embodiment 3: refer to Figure 1-Figure 10 , In this embodiment, it is basically the same as the first embodiment, and it is more optimized that a plurality of scraper plates 22 are arranged on the lower side of the breaker 3, and a number of inverted blades 22 are fixedly installed on the lower side of the breaker 3 corresponding to the scraper plates 22. The hook piece 8 and the end of the scraper plate 22 away from the middle of the breaker 3 are hinged with a vertical plate 23. The upper end of the support base 1 is provided with a number of sliding grooves 3 24 corresponding to the vertical plate 23. The vertical plate 23 is slidably connected to the support base 1, so One end of the vertical plate 23 away from the middle of the breaker 3 is fixedly connected with a second spring 25, and one end of the second spring 25 away from the middle of the breaker 3 is fixedly connected with a connecting plate 26, and the lower end of the connecting plate 26 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com