Bidirectional compensation control method for temperature and pressure of mold in injection molding process

A technology of two-way compensation and control method, applied in the field of mold temperature and pressure control, can solve the problem of not considering the temperature and pressure balance control of melt fluidity, and achieve the effect of ensuring utilization and cost control, improving efficiency, and controlling precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

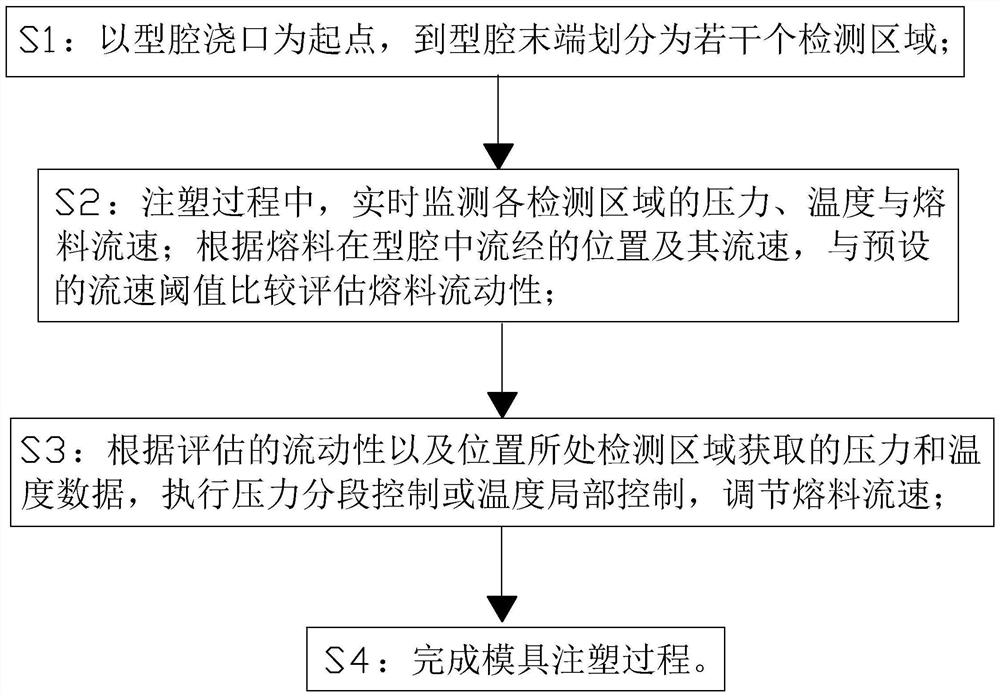

[0056] A bidirectional compensation control method for mold temperature and pressure in an injection molding process in this embodiment, such as figure 1 shown, including the following steps:

[0057]A bidirectional compensation control method for mold temperature and pressure in an injection molding process, comprising the following steps:

[0058] S1: From the cavity gate 3 as the starting point, it is divided into several detection areas to the end of the cavity.

[0059] The division process of the detection area is as follows:

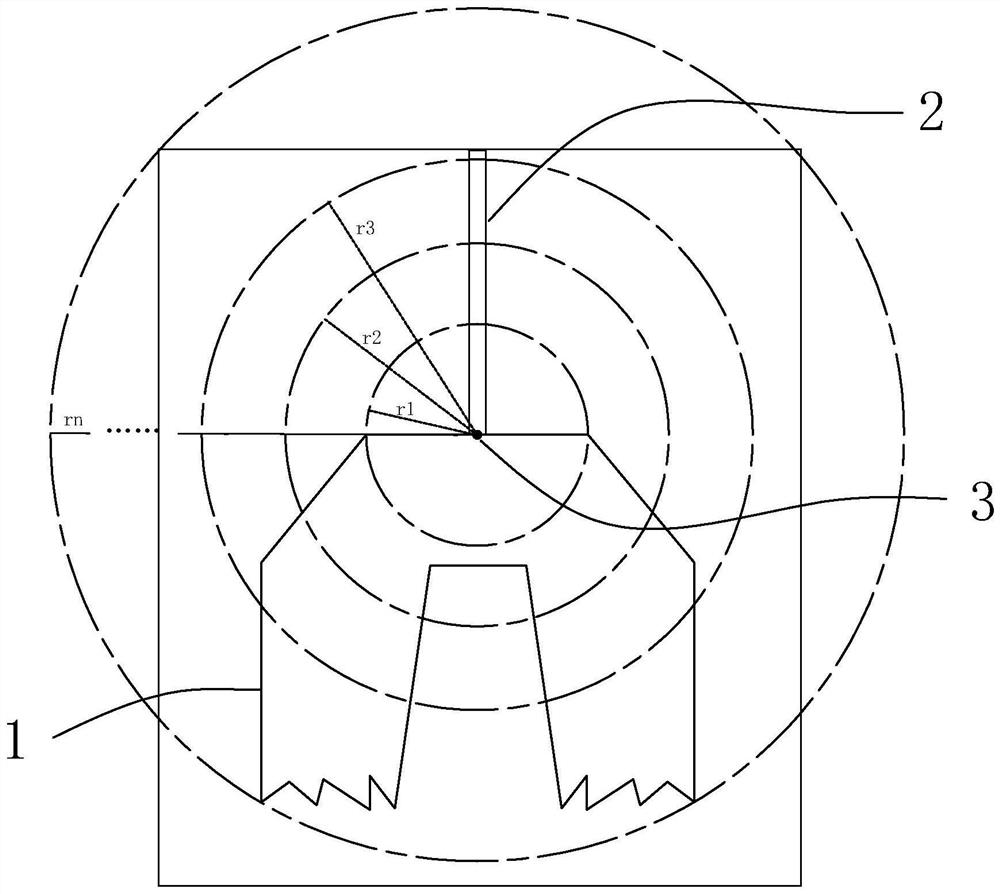

[0060] Set a number of radii, take the cavity gate 3 as the center of the sphere, and determine the detection sphere respectively.

[0061] In this embodiment, as figure 2 As shown, the set radii expand sequentially, including the first radius r1, the second radius r2, the third radius r3...the nth radius rn, until the end of the cavity 1 is also included in the detection sphere. Each detection sphere is a concentric sphere with the same sphe...

Embodiment 2

[0101] A bidirectional compensation control method for mold temperature and pressure in an injection molding process of the present embodiment, further comprising:

[0102] S5: Transfer the injection-molded product to an incubator for a rated time.

[0103] The products after injection molding are kept warm in the incubator to reduce the time occupied by the injection mold and improve the injection efficiency. Avoid the deformation of the product due to the rapid cooling during the cooling process.

[0104] A heat preservation water circuit is arranged outside the heat preservation box, and the heat preservation water way is filled with the outlet water of the cooling water circuit. Make full use of the cooling water in the cooling water circuit, use the cooling water circuit that has been heated up after use for heat preservation, make full use of resources and reduce energy consumption.

[0105] The method of this implementation also includes the heat preservation process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com