Quick start-stop type hazardous waste incineration device and incineration method

An incineration device, start-stop technology, applied in the field of rapid start-stop hazardous waste incineration device, can solve the problem of hazardous waste disposal reliability, environmental protection and economic efficiency are not easy to achieve good results, hazardous waste components are complex, disposal technology Problems such as difficult equipment, to achieve the effect of improving the start-stop switching capability and device processing efficiency, reducing the start-up warm-up time, and improving heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

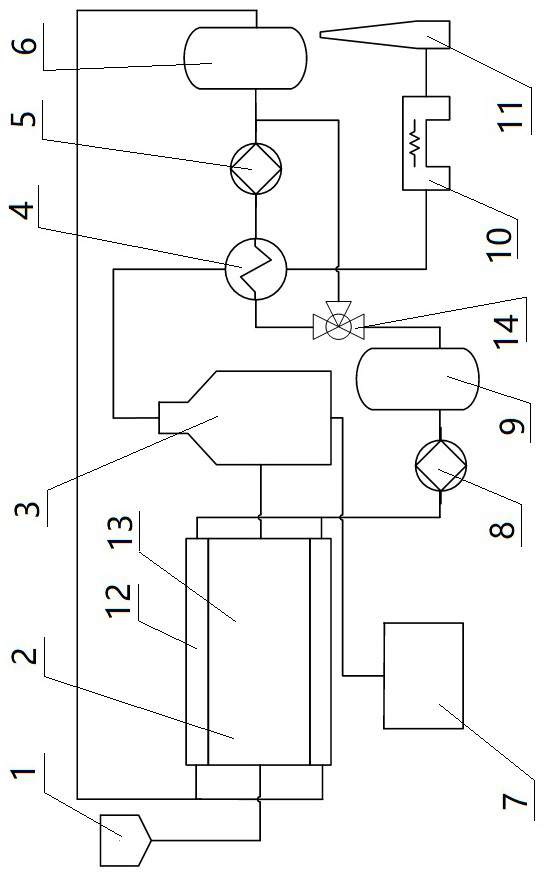

[0022] A quick start-stop type hazardous waste incineration device, which is composed of: a quick-start-stop incinerator 2, the quick-start-stop incinerator includes an incinerator body 13, and an incinerator melting furnace is installed on the outer layer of the incinerator body. Salt shell 12, the inlet of the incinerator body is connected with the hazardous waste storage bin 1, the outlet of the incinerator body is connected with the inlet of the burn-out furnace 3, the bottom outlet of the burn-out furnace is connected with the slag bin 7, and its The upper flue gas outlet is connected with the salt and smoke heat exchanger 4, the salt and smoke heat exchanger is respectively connected with the low temperature molten salt pump 5, the three-way valve 14 and the flue gas purification equipment 10, and the low temperature molten salt pump is connected with the low temperature molten salt pump 5, the three-way valve 14 and the flue gas purification equipment 10 respectively. Th...

Embodiment 2

[0024] According to the rapid start-stop type hazardous waste incineration device described in Embodiment 1, the high-temperature molten salt tank is connected to the high-temperature molten salt pump 8, and the outlet of the high-temperature molten salt pump is connected to the inlet of the molten salt shell of the incinerator , the low temperature molten salt tank is connected with the outlet of the molten salt shell of the incinerator, and the flue gas purification equipment is connected with the chimney 11 .

Embodiment 3

[0026] According to the incineration method of the rapid start-stop type hazardous waste incineration device described in the embodiment 1-2, the method comprises the following steps:

[0027] The first is to use the hazardous waste storage silo to store various solid hazardous wastes. The quick start and stop incinerator is composed of the central incinerator body and the outer layer of the incinerator molten salt shell. The outer layer of the quick start and stop incinerator is equipped with a mechanical transmission device. , which can be rotated in one direction or reciprocating along the circumferential direction. The salt-smoke heat exchanger is respectively provided with a flue gas passage and a molten salt passage, and the flue gas and molten salt in the passage only conduct heat transfer and no mass transfer;

[0028] The outlet of the hazardous waste storage bin is connected to the inlet of the incinerator body, and the hazardous waste enters the inlet of the incinera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com