Refrigerating system of air conditioner

An air-conditioning refrigeration and condenser technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as easy retention of liquid refrigerant and lubricating oil, no mention of the length design of the liquid return pipe, and unfavorable system energy saving. , to eliminate the phenomenon of liquid storage, improve the circulation of refrigerant, and improve the effect of operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

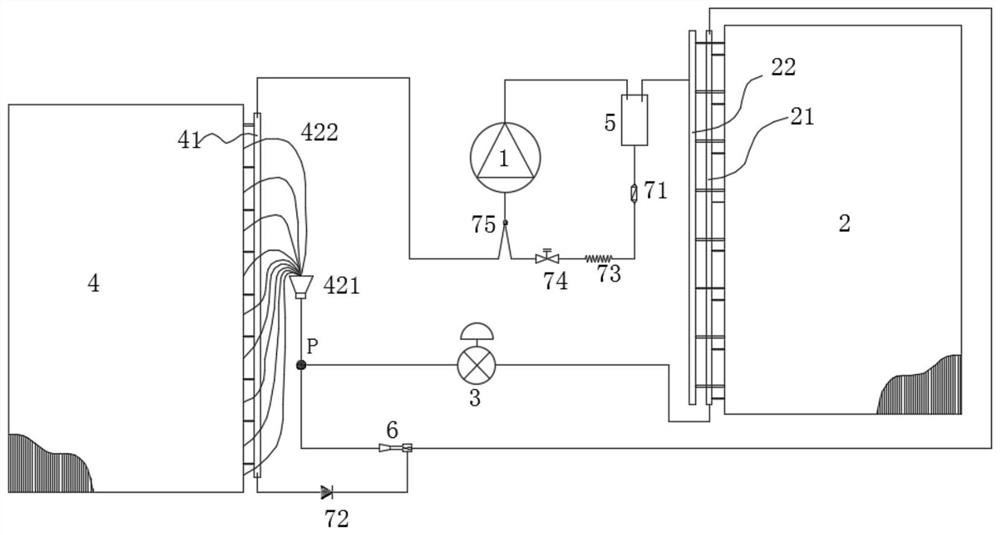

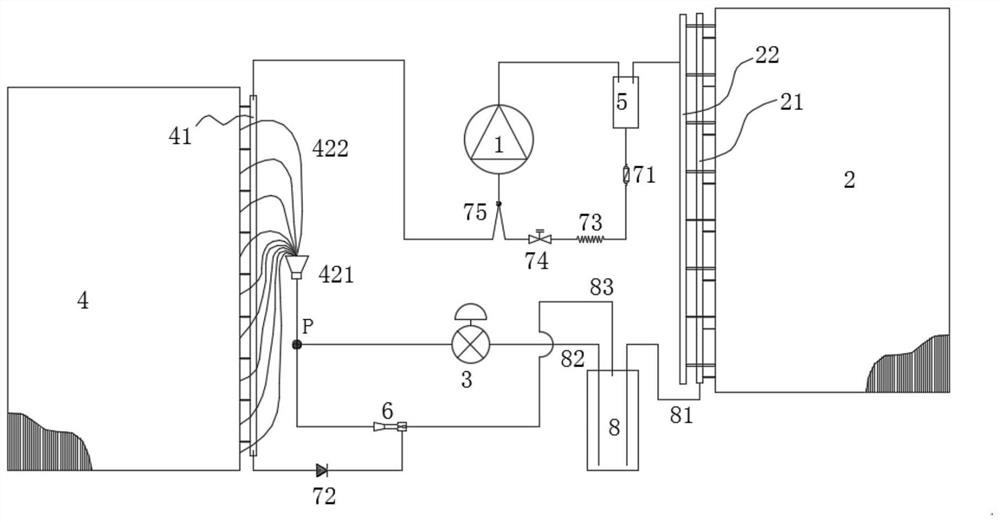

[0021] see in combination figure 1 and figure 2 As shown, according to an embodiment of the present invention, an air conditioning and refrigeration system is provided, including a compressor 1, a condenser 2, a first throttle element 3 (specifically, an expansion valve), and an evaporator 4. The compressor 1, The condenser 2, the first throttling element 3, and the evaporator 4 are connected in sequence to form a refrigeration cycle, and further includes an ejector 6, which can connect the liquid collecting pipe 21 of the condenser 2 to the first section. Outlet line of flow element 3 (eg figure 1 and figure 2 The accumulated liquid in the evaporator 4 is mixed and pressurized at the outlet of the ejector 6 and enters the evaporator 4 under the action of the pressure difference between the P point position in the above. In this technical solution, the high-pressure refrigerant fluid (gas phase or liquid phase) in the header 21 enters the nozzle from the inlet of the ejec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com