Preparation method of density gradient column

A density gradient and density technology, applied in the direction of material analysis by observing sunken objects, can solve the problems of beginners unable to prepare density gradient columns, incomplete drugs, etc., and achieve the effect of detailed operation steps and high success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

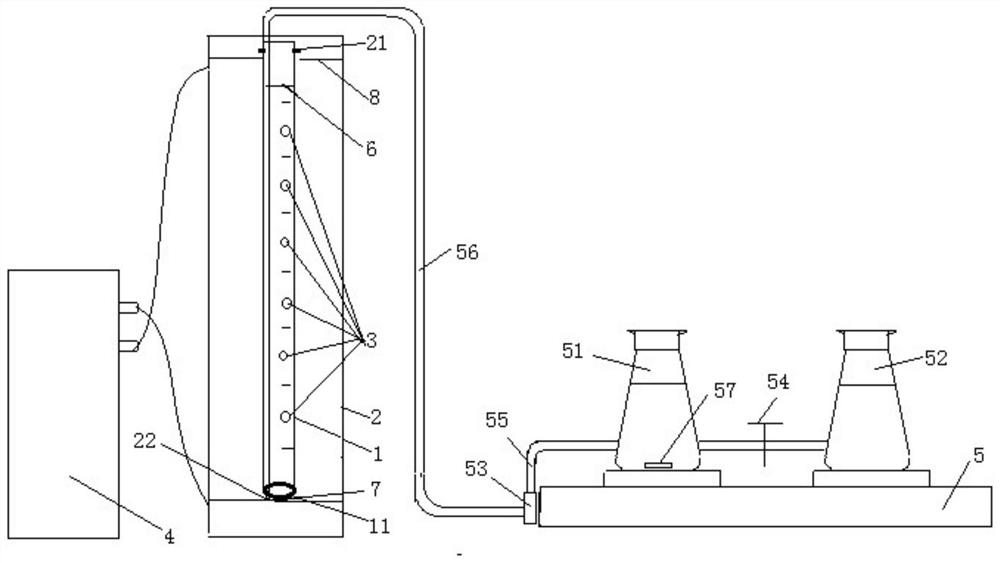

Image

Examples

preparation example Construction

[0049] This embodiment provides a method for preparing a density gradient column. According to the bulk density value of the product to be tested, the target position of the product in the density gradient tube is designed, the float and the drug used are selected, and the light used for preparing the density gradient column is reversely pushed out. The preparation method of liquid and heavy liquid is given, and the detailed preparation method of density gradient column is given, which includes the following steps:

[0050] Float preparation steps: Determine the number and density of the required floats according to the bulk density range of the product to be tested; and preprocess the selected floats.

[0051] Among them, 1) According to the volume density range of the product to be tested, the detection accuracy requirements, the target position where the float with the largest density is suspended in the density gradient column and the target position where the float with th...

Embodiment 1

[0102] In this example, a density gradient column for detecting the density of carbon fiber is prepared. The main steps are as follows:

[0103] Float preparation steps: The bulk density of the carbon fiber to be tested is about (1.795-1.805) g / cm 3 , in order to make the sample to be tested stably suspend in the density gradient column between 30-40cm, the maximum liquid level is designed to be about 70cm in the density gradient tube, and it is planned to evenly disperse 5 floats between the 10cm-60cm scale, so choose 5 floats were set, and the density values were 1.7883g / cm 3 , 1.7949g / cm 3 , 1.8012g / cm 3 , 1.8144g / cm 3 , 1.8232g / cm 3 . Since the float has been in use, after salvaging it from the density gradient tube, soak the float in carbon tetrachloride.

[0104] Here, 1.8232-1.7883=0.0349, 0.0349÷5×7=0.049, which meets the accuracy requirements of bulk density detection: accuracy requirements≤±0.001g / cm 3 When the overall density difference is not more than 0....

Embodiment 2

[0149] This example prepares a density gradient column for detecting the density of the precursor. The main steps are as follows:

[0150] Float preparation steps: the bulk density of the raw silk to be measured is about (1.180-1.190) g / cm 3 , in order to make the position of the sample to be tested stably suspended in the density gradient column between 30-40cm, the maximum liquid level is designed to be about 70cm in the density gradient tube, and it is planned to evenly disperse 5 floats between the 10cm-60cm scale, so choose 5 floats were set, and the density values were 1.1689g / cm 3 , 1.1721g / cm 3 , 1.1802g / cm 3 , 1.1875g / cm 3 , 1.1956g / cm 3 . Since the float has been in use, after salvaging it from the density gradient tube, soak the float in xylene.

[0151] Here, 1.1956-1.1689=0.0267, 0.0267÷5×7=0.037, which meets the accuracy requirements of bulk density detection: accuracy requirements≤±0.001g / cm 3 When the overall density difference is not more than 0.05g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com