Cell panel surface treatment device and process

A technology of surface treatment device and battery plate, applied in primary battery, device for coating liquid on the surface, surface pretreatment, etc., can solve the problems of inability to fix, the material is not neat enough, and the secondary deviation of the material, so as to avoid the second problem. The effect of the secondary offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

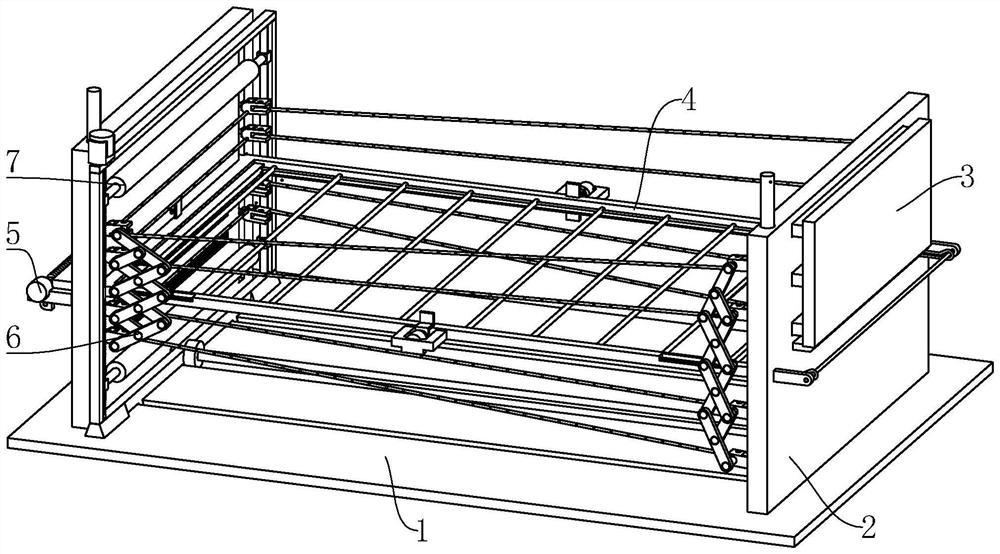

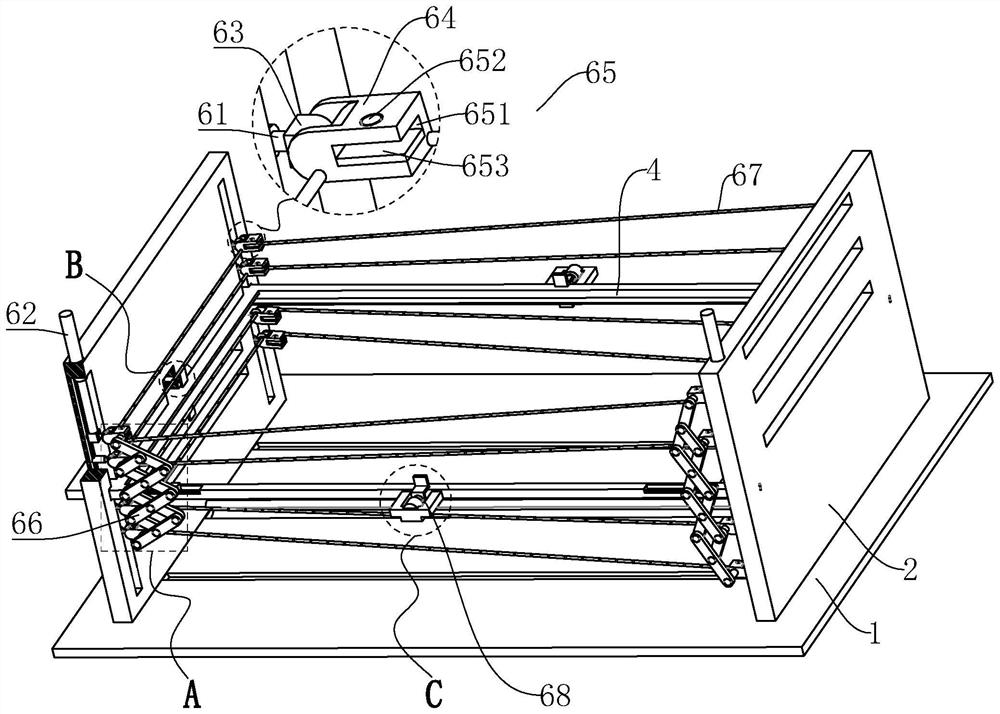

[0042] refer to figure 1 As shown, the battery plate surface treatment device includes a base 1 and a support plate 2 symmetrically arranged on the upper end of the base 1. The support plate 2 is provided with a blowing mechanism 3 for blowing and dusting the material foil raw materials, and a middle part of the support plate 2 is provided. There is a supporting frame 4 for supporting the battery plate, and a supporting mechanism 5 is arranged on the supporting frame 4. The supporting mechanism 5 can support the welded battery sheet, and the supporting plate 2 is located on the supporting frame 4. The left and right sides of the material foil are also provided with a clamping and gluing mechanism 6 for clamping the film-shaped raw materials of the material foil, and it can also be glued, because each film-shaped material of the material foil is stacked up and down. Therefore, the base 1 is provided with a pressing mechanism 7 for pressing the film-like constituent material of ...

Embodiment 2

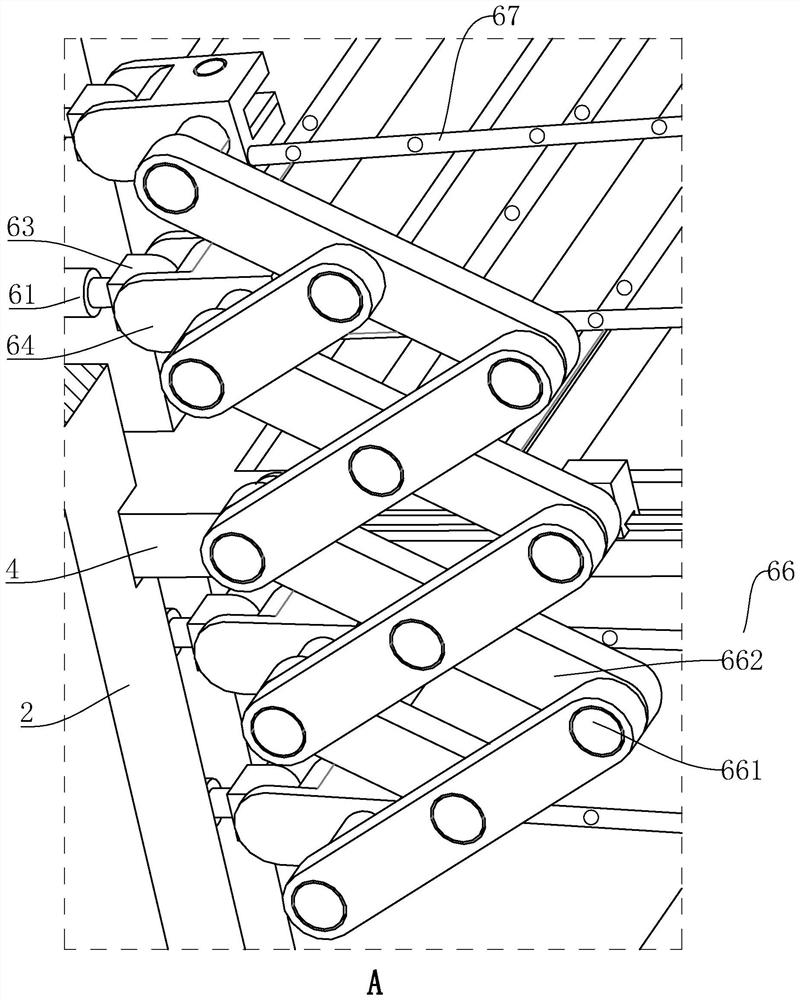

[0049] refer to image 3 As shown, on the basis of the first embodiment, in order to facilitate the adjustment of the position of the clamping blocks 64 so that the respective raw materials of the material foil can be attached to each other, a A scissor branch chain 66 that drives a plurality of clamping blocks 64 to move synchronously; specifically, the scissor branch chain 66 includes a pin shaft rod 661 arranged at the front end of the clamping block 64, and the outer surface of the pin shaft rod 661 is rotated and matched with The scissor rods 662 are stacked in the front and rear and are distributed in an X shape, and the middle parts of the scissor rods 662 on the front and rear sides and the other end of the scissor rods 662 are also rotated through the pin shaft 661. way to connect.

[0050] The pin shaft 661 corresponding to the position of the support frame 4 and close to the middle side of the support frame 4 is slidingly matched with the support frame 4 left and r...

Embodiment 3

[0054] refer to Figure 5As shown, on the basis of the second embodiment, in order to support the welded battery without affecting the bonding of the film-like constituent material of the material foil on the lower side of the battery with the battery, the supporting The frame 4 is provided with a supporting mechanism 5; specifically, the supporting mechanism 5 includes an installation side plate 51, a limit rod 52, an installation side block 53, a winding rod 54, a rotating motor 55, a fixed block 56, a connecting rope 57 and a bearing. The support rod 58, the right side of the right support plate 2 is provided with a front and rear symmetrical installation side plate 51, a limit rod 52 is arranged between the installation side plates 51 by means of rotation and cooperation, and the left support plate 2 is provided with A rectangular through slot, and the left end of the support frame 4 passes through the rectangular through slot and is located on the left side of the left su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com