Hoisting structure for assembly type composite floor slab

A composite floor slab and assembled technology, which is applied in building construction, transportation and packaging, and load hanging components, etc., can solve the problems of prefabricated slab instability, safety hazards, and unstable center of gravity of prefabricated slabs, and achieve convenient hoisting and flipping , Improve the effect of use, and the effect of turning smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

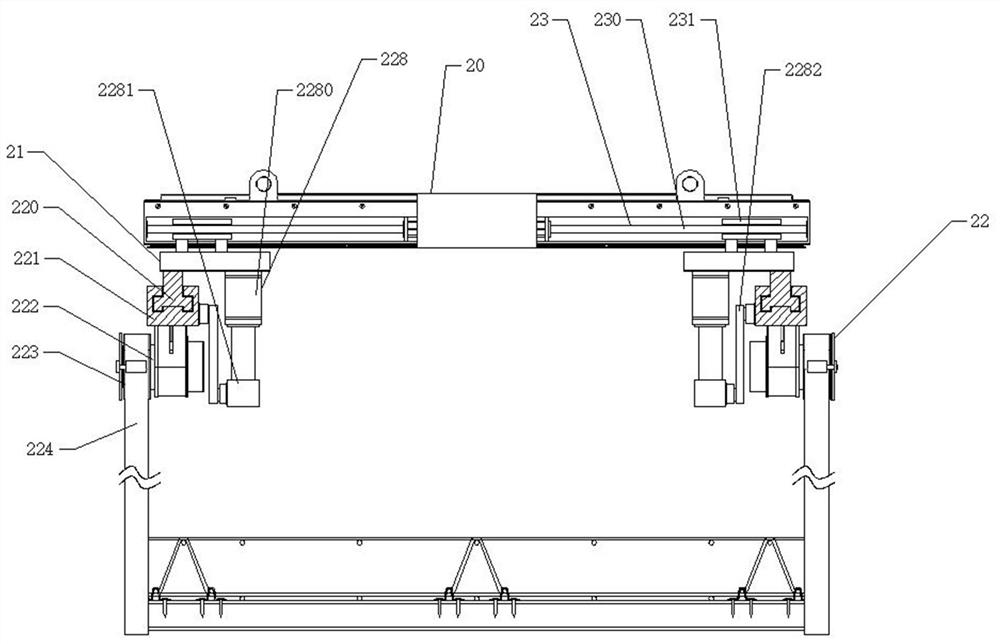

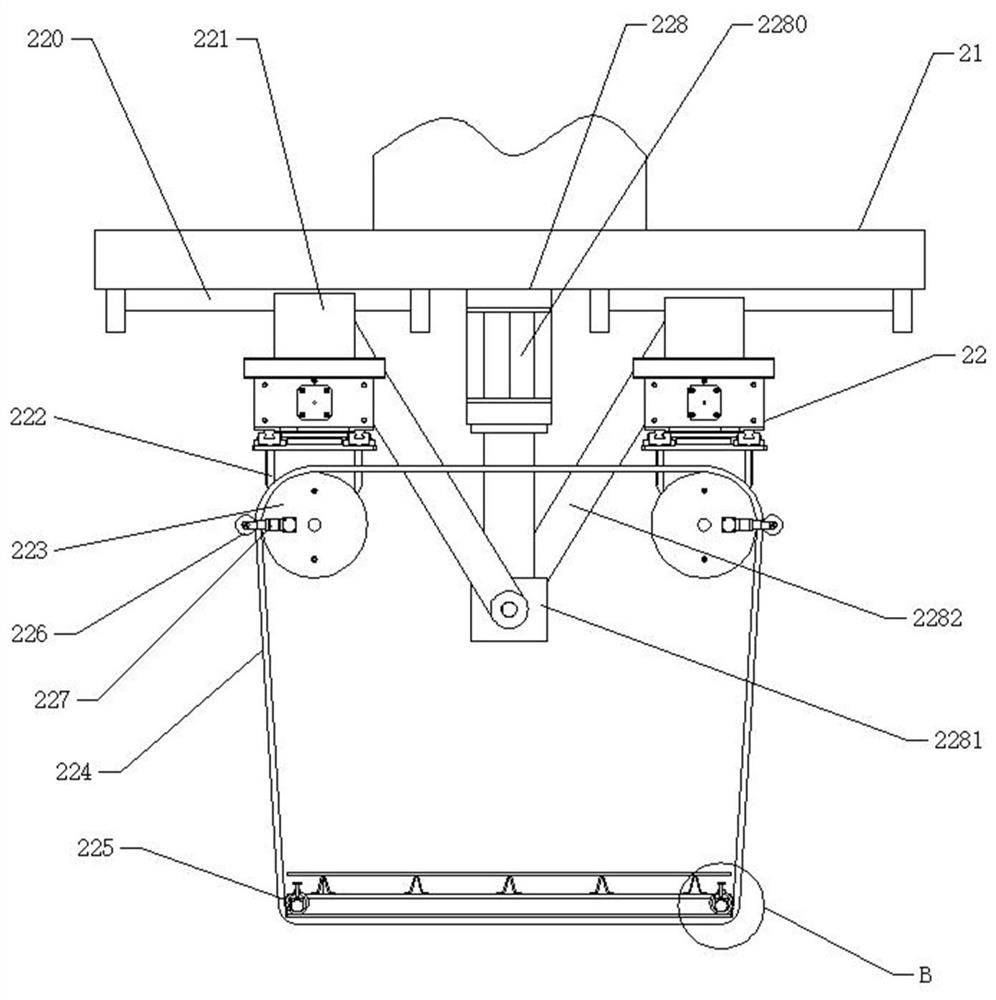

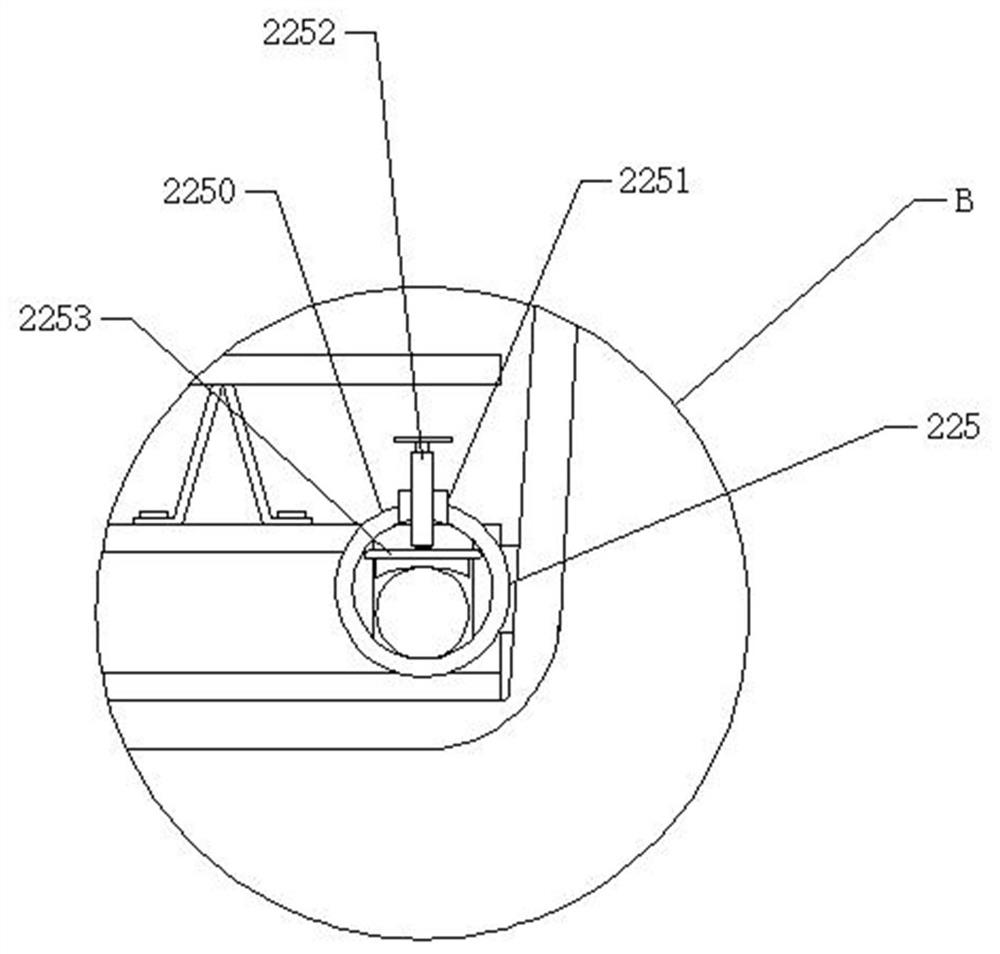

[0033] like Figure 1 to Figure 5As shown in the figure, this embodiment provides a hoisting structure for an assembled composite floor slab, which is used for hoisting the integrated prefabricated panel in Embodiment 1, including a hoisting plate 20 and a hoisting plate 20 symmetrically arranged on both sides of the bottom of the hoisting plate 20 in the length direction. The hoisting bracket 21 is perpendicular to the length direction of the hoisting plate 20, and the bottom of any hoisting bracket 21 is installed with a flipping hanger 22; , corresponding to the sliding block 221 embedded in the two sliding rails 220 , corresponding to the synchronous turning motor 222 installed at the bottom of the two sliding blocks 221 , and the hanging wheel 223 connected to the output end of the synchronous turning motor 222 . The synchronous lifting belt 224 on the outer surface of the wheel 223 and the clamping part 225 symmetrically arranged in the synchronous lifting belt 224 for f...

Embodiment 2

[0040] like figure 1 As shown, on the basis of Embodiment 2, in this embodiment, an adjustment mechanism 23 for adjusting the distance between the hoisting brackets 21 is further provided at the bottom of the hoisting plate 20 . , a sliding sleeve 231 connected with the hoisting bracket 21 on the top and bottom of the distance adjusting rod 230 is sleeved, and the sliding sleeve 231 and the distance adjusting rod 230 are screw-nut transmission pairs.

[0041] What needs to be explained here is that most of the hoisting equipment on the market can only hoist prefabricated panels of a fixed size when hoisting prefabricated panels. In the actual construction and use process, due to the different installation positions of prefabricated panels, its length (dimension) It is also different. Therefore, there are many inconveniences in using traditional hoisting equipment to hoist the prefabricated panels on the construction site. For this reason, in this scheme, an adjustment mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com