On-line switching device and method for methanol-to-low carbon olefin fluidized bed catalyst

A technology of fluidized bed catalysts and low-carbon olefins, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry. It can solve problems such as catalyst loss, reduce fluidized bed catalyst switching time, and affect the stable operation of MTO devices. The effect of the total switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

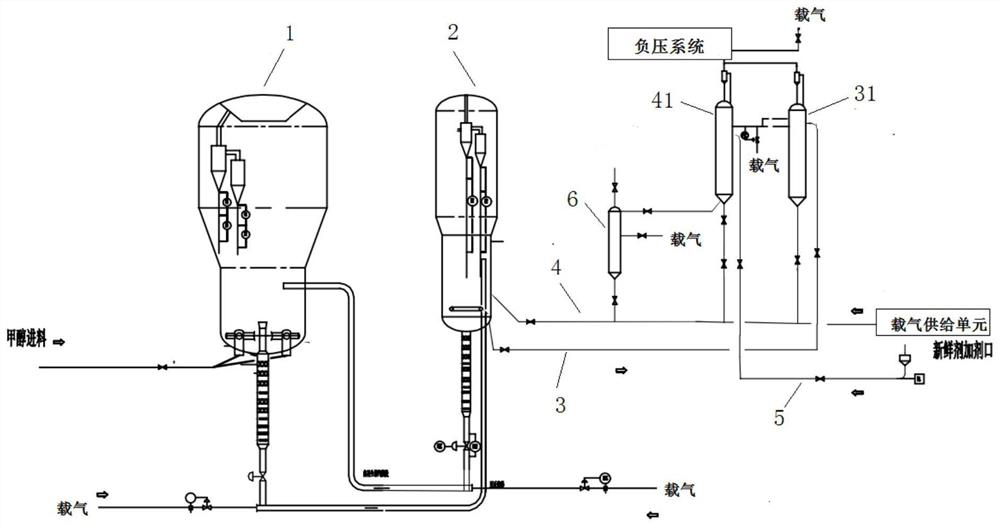

Embodiment 1

[0091] The dosing port is 1m away from the unloading port, and the carrier gas unit pressurizes the dosing tank 41 to 0.38MPa. Step 1) The total amount of Zhongke MTO catalyst added to the regenerator 2 each time is 4t, and the dosing flow rate is 0.6 t / h, in step 2), the time for the mixed catalyst to circulate back and forth between the regenerator 2 and the reactor 1 is 7h, and the amount of the mixed catalyst unloaded each time in step 3) is 3wt% of the catalyst in the regenerator 2. Step 3) The time for each unloading of the mixed catalyst is 7h, the total amount of catalyst in the reactor 1 and the regenerator 2 is 100t, and the temperature of the catalyst flowing through the unloading pipeline 3 is 100°C; Zhongke MTO catalyst The loss rate was 9.4%.

Embodiment 2

[0093] The dosing port is 3m away from the unloading port, and the carrier gas unit pressurizes the dosing tank 41 to 0.2MPa. Step 1) The total amount of Zhongke MTO catalyst added to the regenerator 2 each time is 8t, and the dosing flow rate is 0.2 t / h, in step 2), the time for the mixed catalyst to circulate back and forth between the regenerator 2 and the reactor 1 is 24h, and the amount of the mixed catalyst unloaded in step 3) is 15wt% of the catalyst in the regenerator 2. Step 3) The time for each unloading of the mixed catalyst is 2h, the total amount of catalyst in the reactor 1 and the regenerator 2 is 80t, and the temperature of the catalyst flowing through the unloading pipeline 3 is 300°C; Zhongke MTO catalyst The loss rate is 15.2%.

Embodiment 3

[0095] The dosing port is 2m away from the unloading port, and the carrier gas unit pressurizes the dosing tank 41 to 0.5MPa. Step 1) The total amount of Zhongke MTO catalyst added to the regenerator 2 is 2t each time, and the dosing flow is 2t / h, in step 2), the time for the mixed catalyst to circulate back and forth between the regenerator 2 and the reactor 1 is 48h, and the amount of the mixed catalyst unloaded each time in step 3) is 15wt% of the catalyst in the regenerator 2. Step 3 ) The time of each unloading of the mixed catalyst is 2h, the total amount of catalyst in the reactor 1 and the regenerator 2 is 120t, and the temperature of the catalyst flowing through the unloading pipeline 3 is 450°C; The loss rate was 13.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com