Fabric printing and dyeing pretreatment equipment

A pretreatment, fabric technology, applied in the direction of fabric surface trimming, textile and papermaking, singeing, etc., can solve the problems of difficult to remove ash, slow temperature rise, etc., to ensure the effect of singeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below:

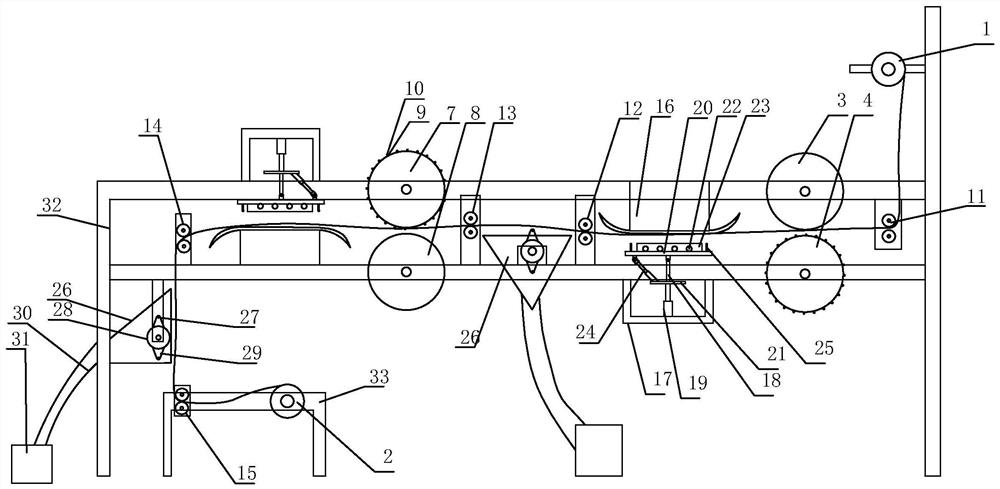

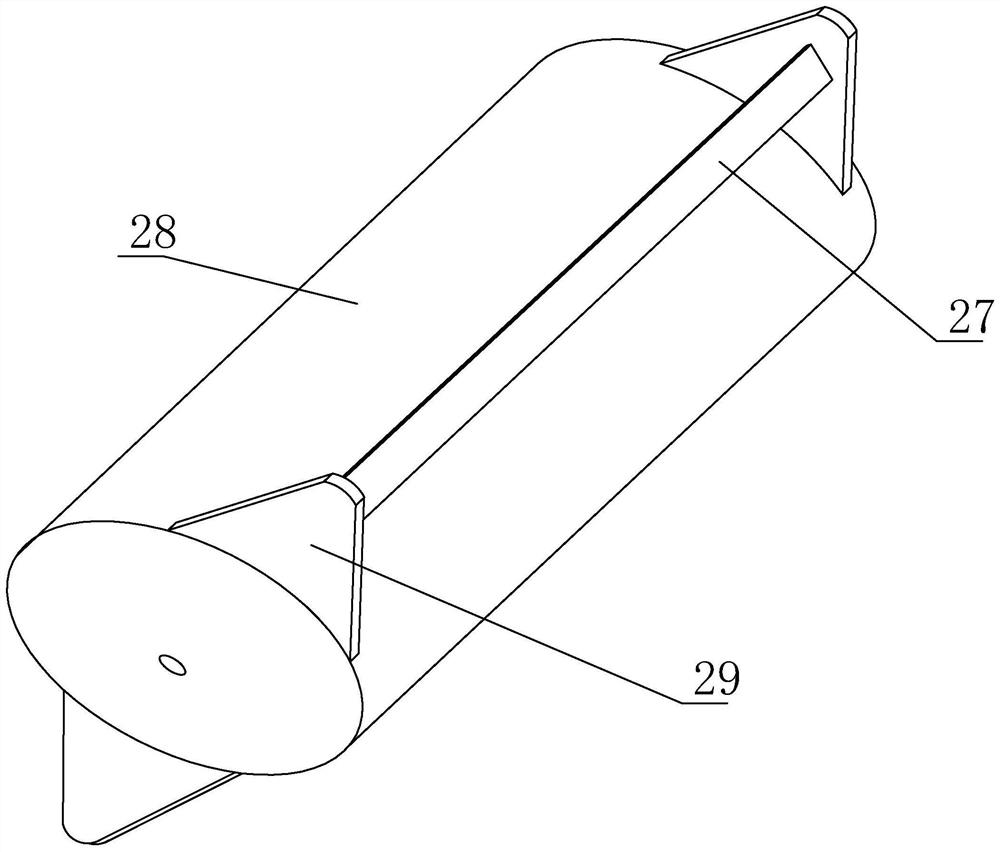

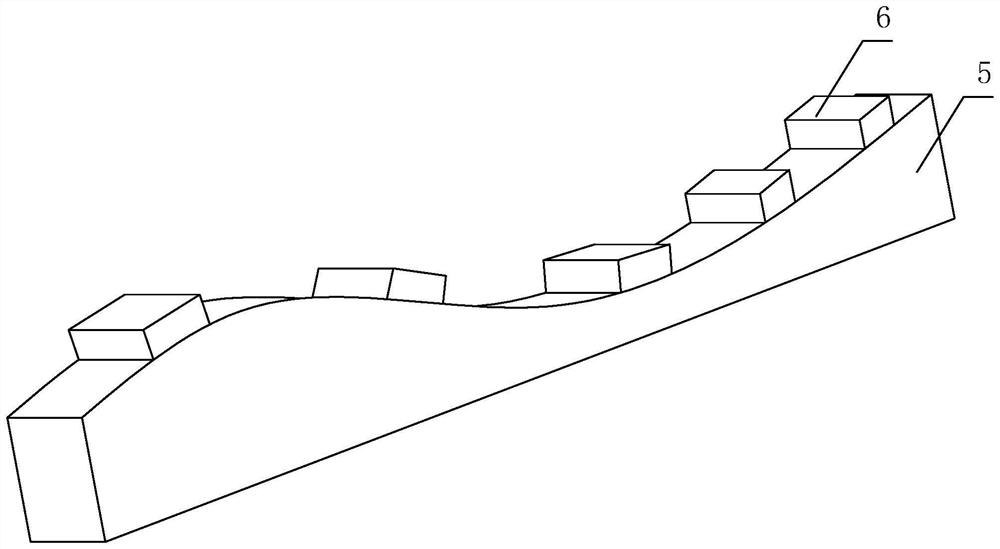

[0021] A fabric printing and dyeing pre-treating equipment, comprising a frame, the front end of the frame is provided with an unwinding roller 1, a first guide roller group 11 is arranged below the unwinding roller 1, and a machine behind the first guide roller group 11 is arranged. A first carding mechanism, a first singeing mechanism, a second conducting roller group 12, a first beating mechanism, a third conducting roller group 13, a second carding mechanism, a second singeing mechanism, and a fourth conducting The roller group 14, the second beating mechanism, the fifth conduction roller group 15 and the winding roller 2, the first carding mechanism can comb the lower surface of the fabric, and the first singeing mechanism can singe the lower surface of the fabric, The first beating mechanism can beat the lower surface of the fabric and absorb dust, the second carding mechanism can comb the lower and upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com