System and method for testing full-stroke sealing performance of hydraulic stand column or jack

A technology of hydraulic column and sealing performance, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of fluid, and by detecting the appearance of fluid at the leakage point, etc., which can solve the problem that the hydraulic column or jack cannot be guaranteed Qualified, hydraulic column or jack top inspection is incomplete, endangering the safety of personnel and equipment in the coal mining face, etc., to achieve the effect of improving the reuse rate, saving manpower, and being easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments and accompanying drawings. Here, the exemplary embodiments of the present invention and their descriptions are used to explain the present invention, but not to limit the present invention.

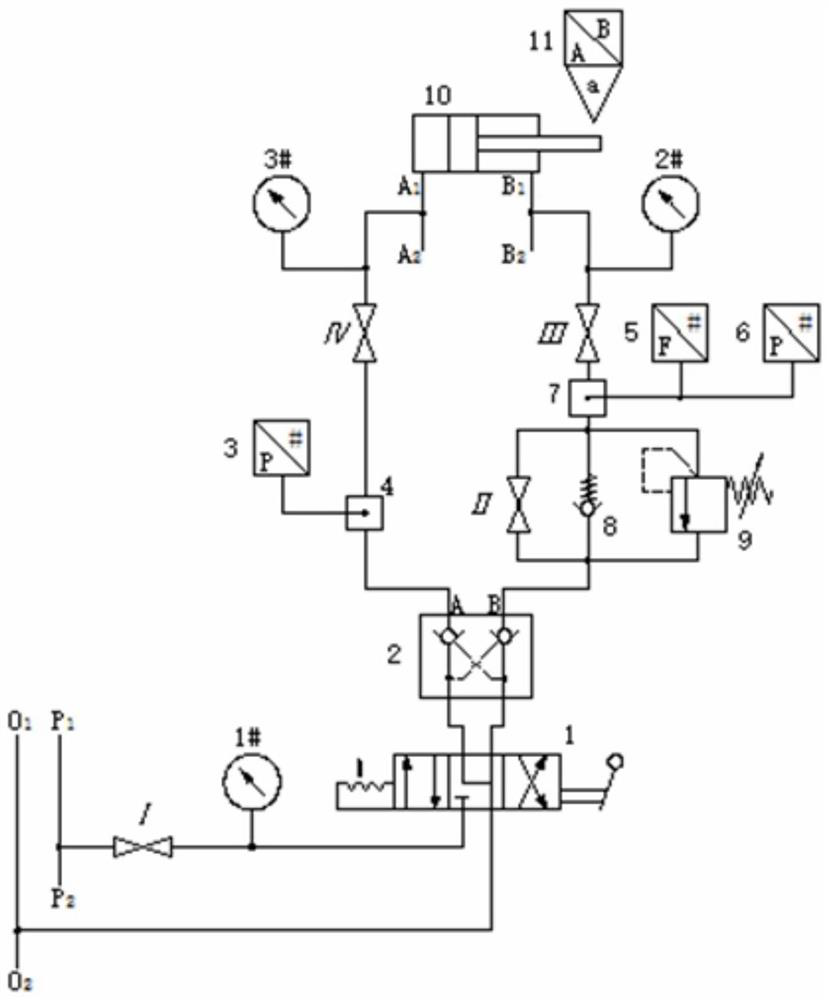

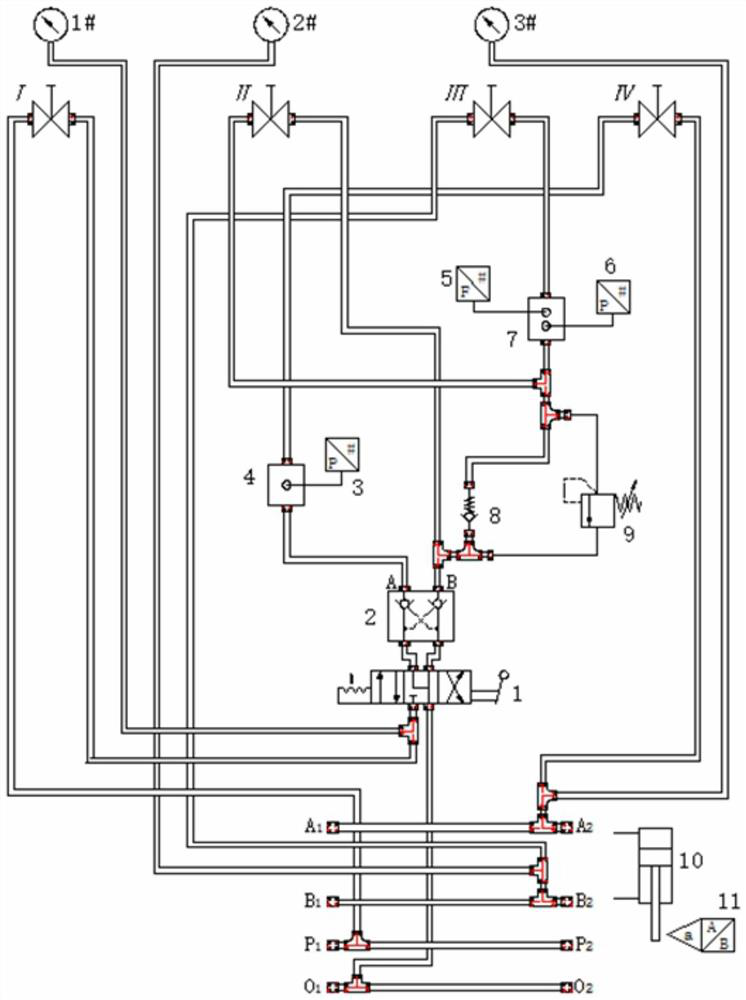

[0033] see figure 1 and figure 2 , a hydraulic column or jack full-stroke sealing performance testing system provided by the embodiment of the present invention consists of a reversing valve 1; a hydraulic lock 2; a first pressure sensor 3; a first oil circuit connection block 4; a flow sensor 5; a second Pressure sensor 6; second oil circuit connection block 7; one-way valve 8; large flow loading safety valve 9; tested hydraulic column or jack 10; acceleration sensor 11; first cut-off valve I; second cut-off valve II; third Globe valve III; fourth globe valve IV; first pressure gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com