Full-stroke sealing performance testing device for hydraulic stand column and jack and using method

A technology of hydraulic column and sealing performance, which can be used in the use of liquid/vacuum for liquid tightness measurement, by measuring the acceleration and deceleration rate of fluid, and by detecting the appearance of fluid at the leak point, etc., can solve the problem of endangering coal mining face personnel and equipment safety, unable to guarantee the qualified column or jack, incomplete detection of the column or jack, etc., to achieve the effect of improving the reuse rate, saving manpower and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]By the description of the embodiments, the present invention will not be understood by the following description, but the specific embodiments given by the applicant should not be regarded as limiting the technical solution of the present invention, any of the technical characteristics. Definitions Change and / or to the form of the present invention should be considered as defined by the technical solutions of the present invention.

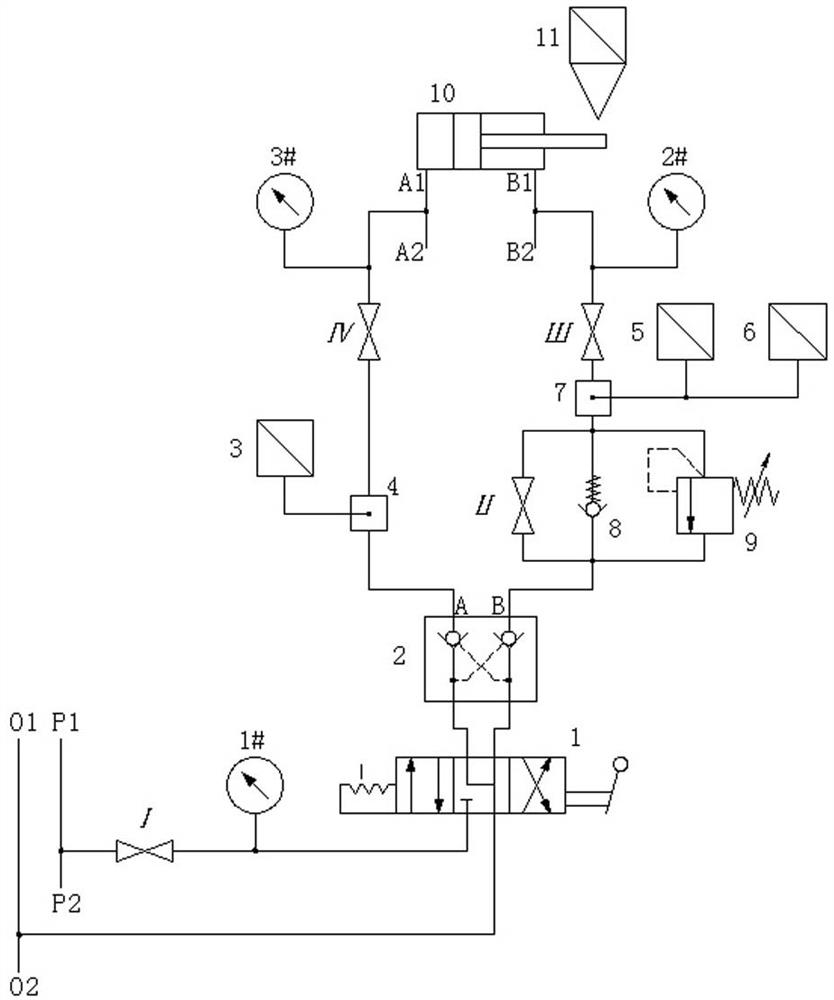

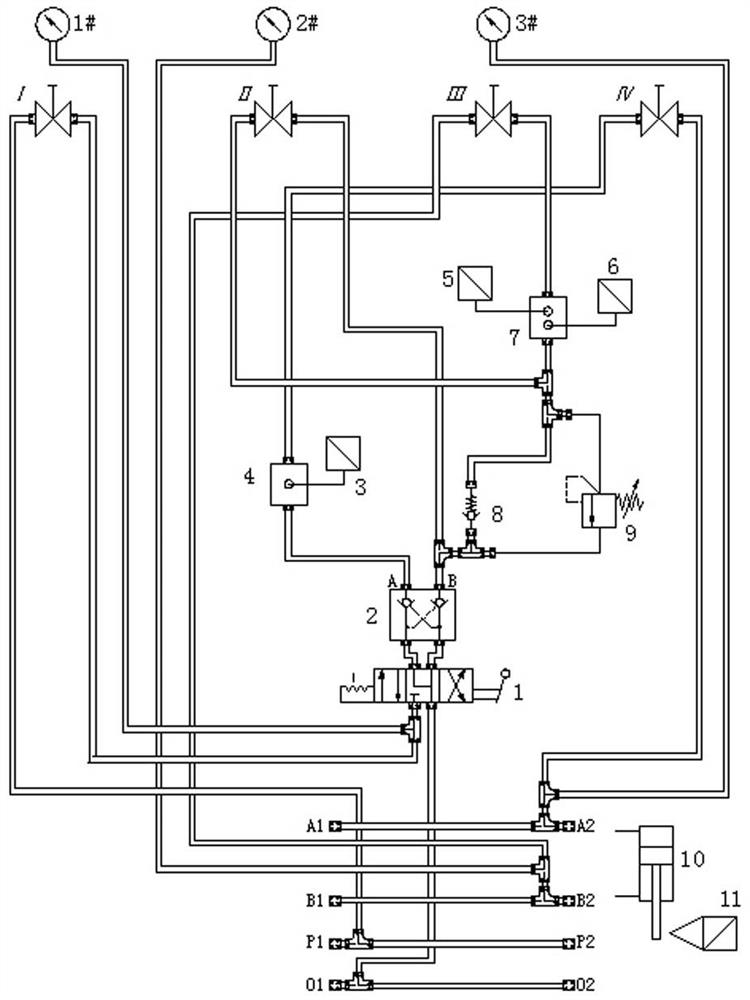

[0039] See Figure 1 to 2 As shown, the technical solution of the present invention is as follows:

[0040] A hydraulic column and a jack full stroke sealing performance test device, from the manipulation valve 1, a hydraulic lock 2, a first pressure sensor 3, a first oil passage connection block 4, a flow sensor 5, a second pressure sensor 6, a second oil passage Connecting block 7, a one-way valve 8, a large flow load safety valve 9, a hydraulic column and a jack 10, an acceleration sensor 11, a first shutoff valve I, a second shutoff valve I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com