Apparatus and process for efficiently producing structured cross-channel filler elements

A cross-channel, structured technology, applied in chemical/physical processes, chemical/physical/physicochemical processes, chemical instruments and methods, etc., can solve problems affecting processing, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

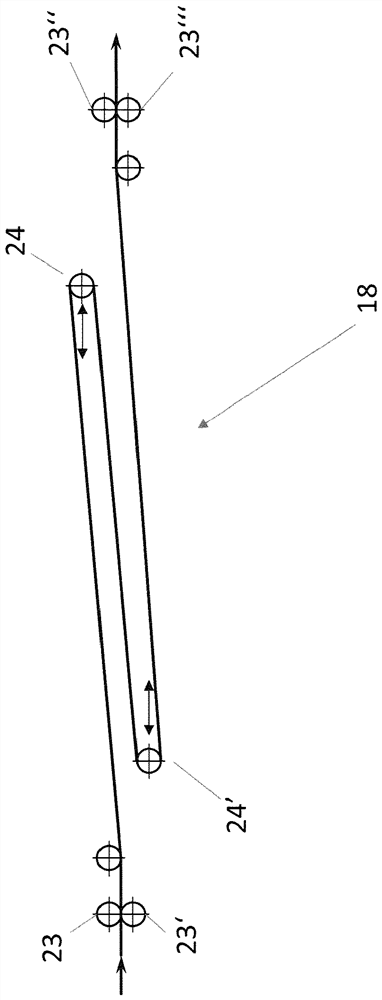

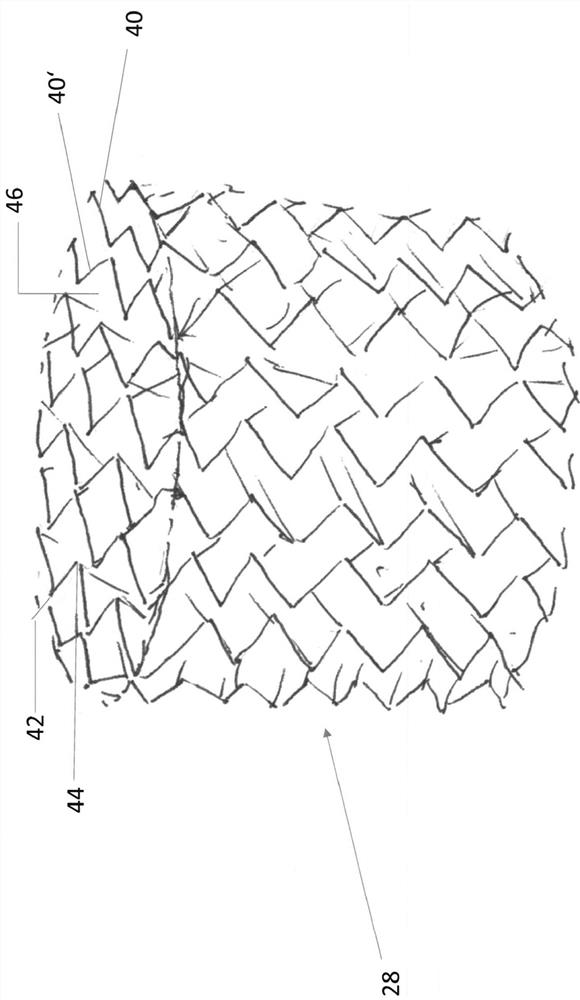

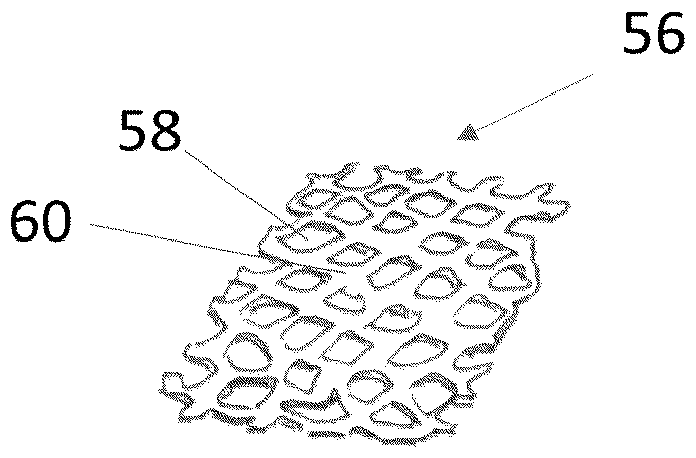

[0082] figure 1 An apparatus 10 for producing structured cross-channel packing elements of a column for mass and / or heat exchange between a heavy fluid phase and a light fluid phase is schematically shown according to one embodiment of the present invention. The apparatus 10 includes, from its upstream end to its downstream end, an uncoiler 12, a stretcher 14 for cutting and stretching the metal sheet into expanded metal sheets, a stretcher 14 for the expanded metal sheet to be produced in the stretcher A calibrator 16 for rolling to a desired thickness, a sheet storage unit 18, a forming machine 20 for forming the rolled expanded metal sheet produced in the A stacker 22 for stacking expanded metal sheets comprising periodic deformations into structured cross-channel packing elements. The uncoiler 12 is a sleeve onto which the metal sheet is wound. During operation of the apparatus 10, the metal sheet is uncoiled from the uncoiler 12 and fed into the stretching machine 14, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com