Isomerization method of cyclohexanedicarboxylic acid

A cyclohexanedicarboxylic acid, isomerization technology, applied in the field of isomerization of cyclohexanedicarboxylic acid, can solve the unproven reaction efficiency, yield and processing performance, t-CHDA is hard, difficult to handle and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

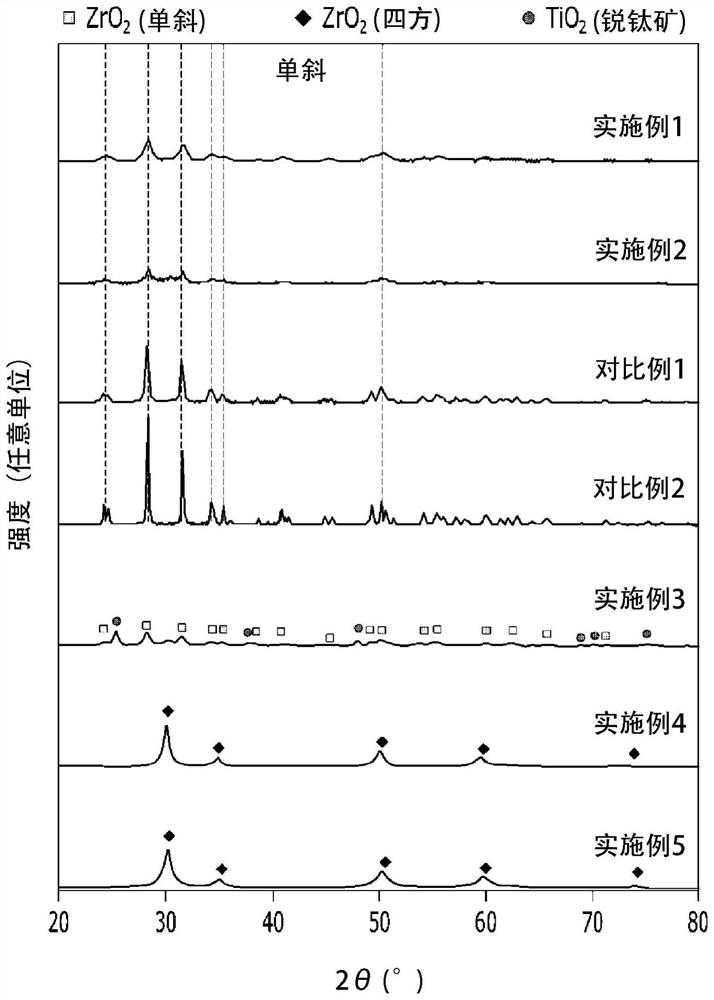

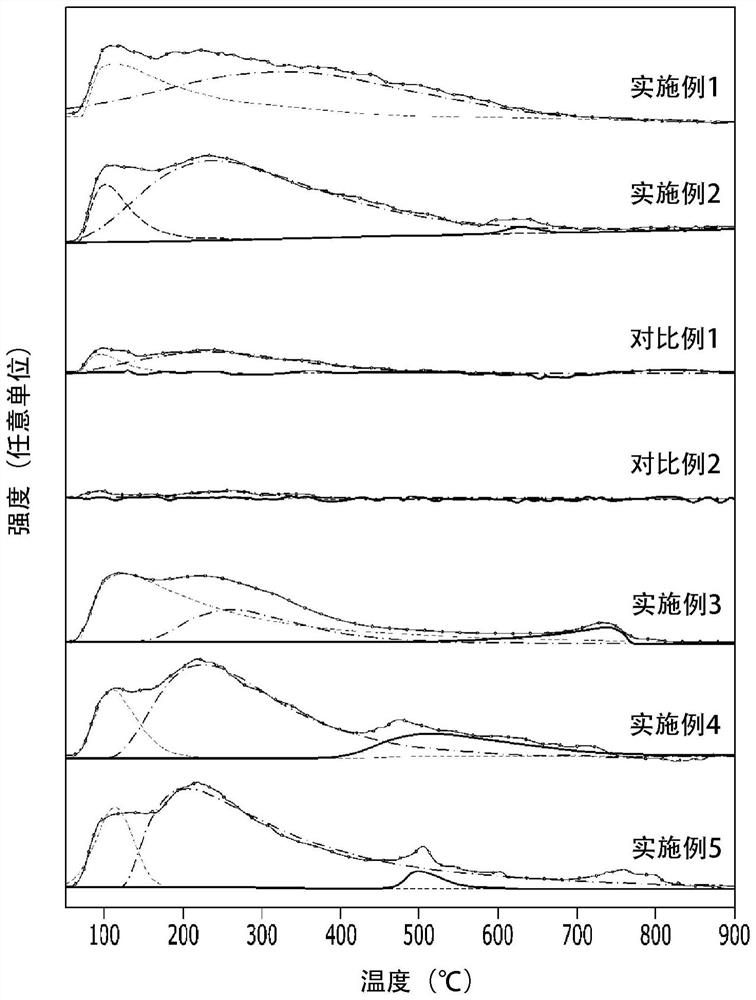

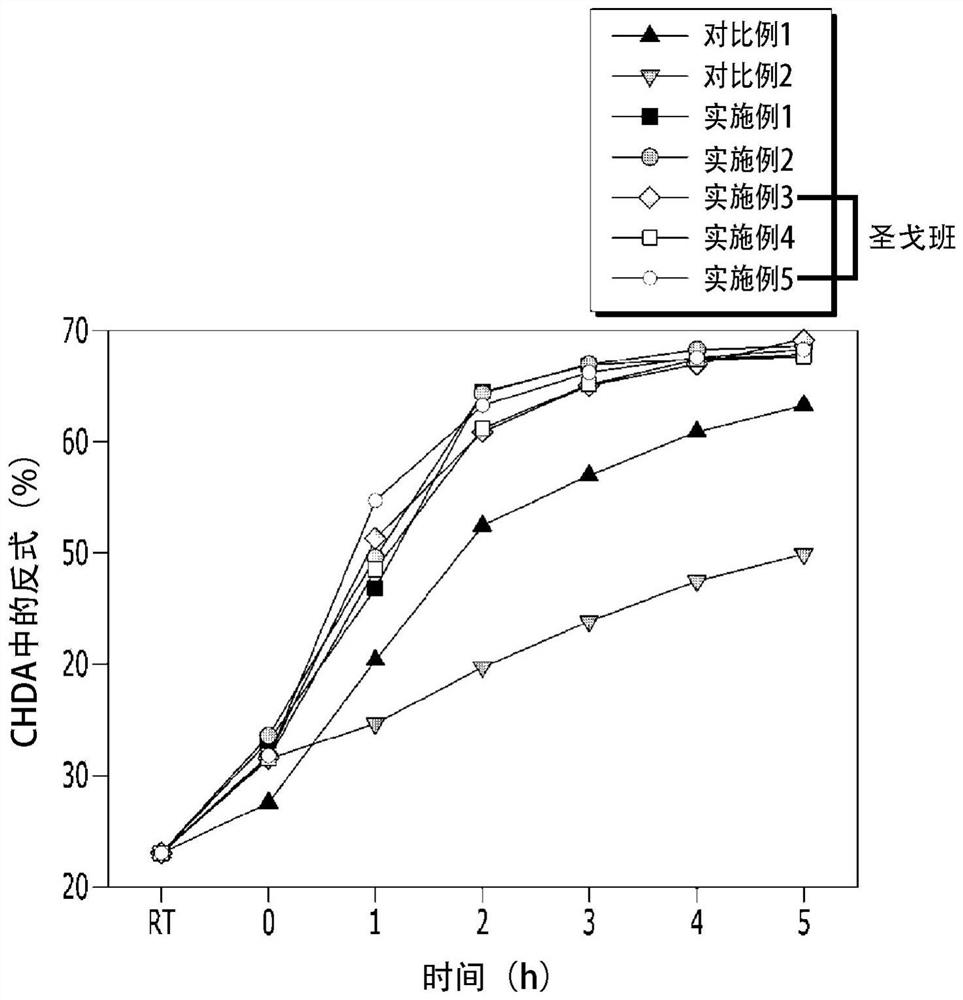

Embodiment 1

[0086] For the isomerization of CHDA, a batch reactor capable of withstanding 300°C and 150 bar was selected as the reactor. 4.05 g of CHDA containing the cis isomer, 1.125 g of zirconia (monoclinic) from Saint-Gobain and 250 g of distilled water as solvent were placed in the prepared batch reactor and stirred at 50 rpm At the same time, the temperature of the mixed solution was raised to 250° C. (CHDA concentration in the solution: 1.6 wt %, zirconia / CHDA weight ratio=0.28). When the temperature of the mixed solution reached 250°C, the stirring speed was increased to 1000 rpm, and the reaction was performed for 5 hours while stirring.

[0087] The BET specific surface area, pore volume and average pore diameter of the zirconia (monoclinic) used here are shown in Table 1 below, and the acid properties are shown in Table 2 below.

Embodiment 2

[0089] The procedure was carried out in the same manner as in Example 1, except that zirconia (monoclinic) from Johnson Matthey was used instead of zirconia (monoclinic) from Saint-Gobain used in Example 1.

Embodiment 3

[0091] Except for using zirconia (monoclinic)-titanium dioxide (anatase) from Saint-Gobain (where the content of titanium dioxide (anatase) in the total mixture (100% by weight) was 41% by weight) instead of the one used in Example 1 The procedure was carried out in the same manner as in Example 1 except for zirconia (monoclinic) from Saint-Gobain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com