Self-cleaning system

A self-cleaning and cleaning scraper technology, applied in the field of self-cleaning systems, can solve problems such as injury to workers' health, slow work speed, and small scope of application, so as to increase the cleaning area, reduce residues, and improve convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

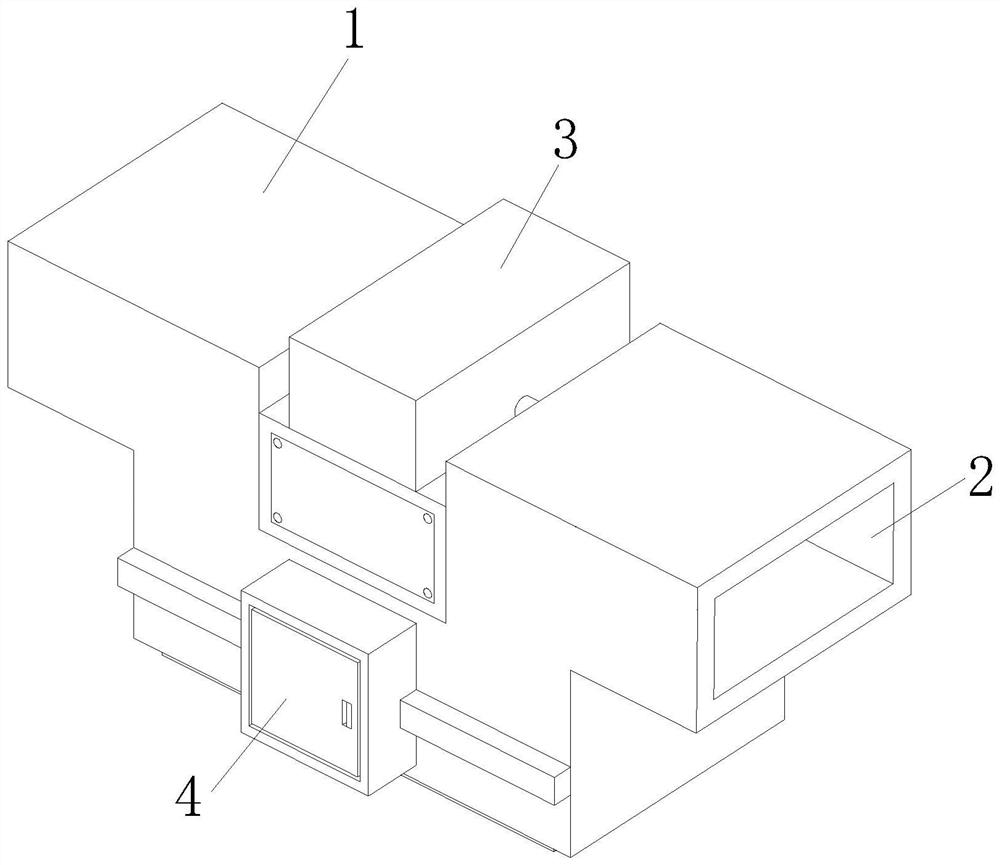

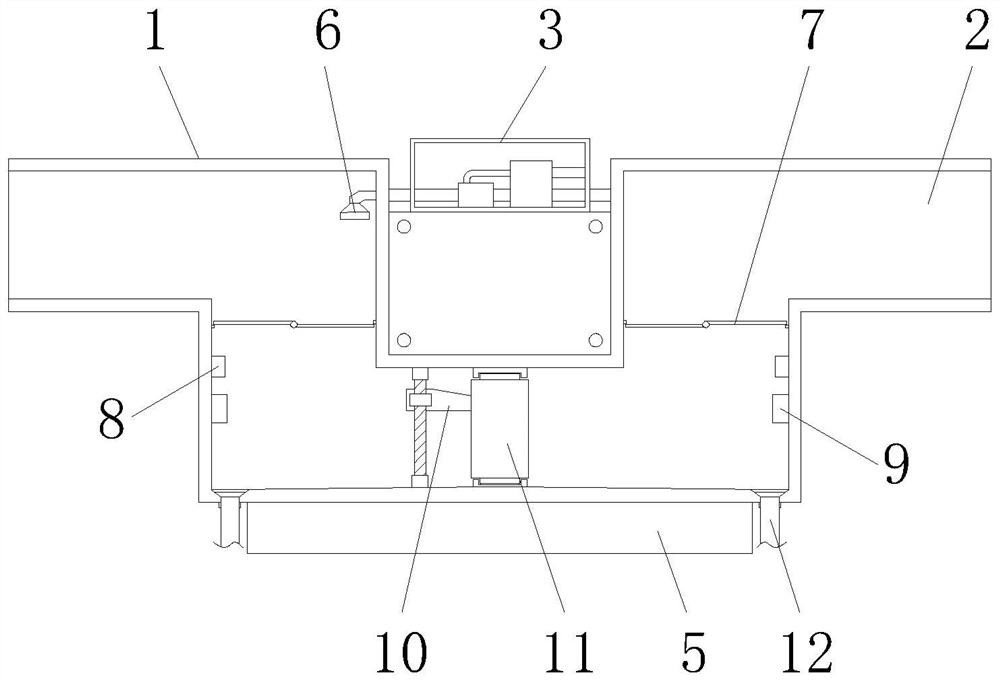

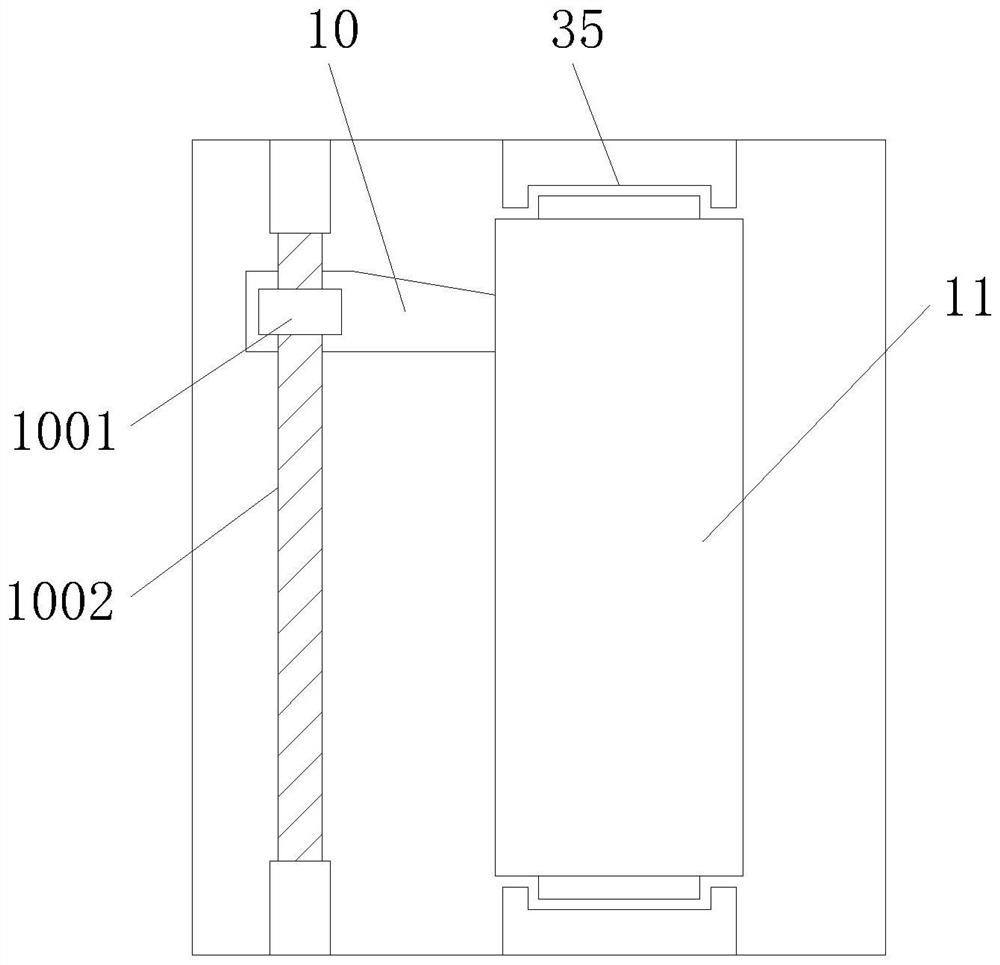

[0031] see figure 1 - Figure 8 , a self-cleaning system, including a purification device 1 and a ventilation duct 2, the lower end of the purification device 1 is fixedly installed with an ultrasonic vibrator 5, the ventilation duct 2 is designed in a "concave" shape, and the ventilation duct 2 is fixedly installed with The water outlet nozzle 6 is movably installed with a sealing valve 7 in the ventilation air duct 2, and the cleaning blade 10 is movably installed in the water outlet nozzle 6. The cleaning blade 10 includes a linkage seat 1001 and a connecting beam frame 1003, and the linkage seat 1001 is connected with internal threads There is a driving link 1002, the connecting beam frame 1003 includes a flushing nozzle 1004 and a flushing joint 1005, the flushing nozzle 1004 is fixedly connected to the outer side of the connecting beam frame 1003, the flushing nozzle 1004 and the flushing joint 1005 communicate with each other, and the cleaning blade 10 is provided with ...

Embodiment 2

[0035] see Figure 9 - Figure 10, a cleaning water tank 3 is fixedly installed on the upper end of the purification device 1, a purification electrostatic field 11 is movably installed in the purification device 1, a mounting bracket 21 is fixedly installed on the outside of the purification device 1, and a winding device 22 is movably installed in the installation bracket 21, and the winding The lower end of the device 22 is fixedly installed with a waterproof curtain 25, the lower end of the purification device 1 is fixedly installed with a protective groove 27, a mounting sensor 28 is fixedly installed in the protective groove 27, and a connecting bracket 23 is fixedly installed in the purification device 1, and the connecting bracket 23 is fixedly installed. A cleaning nozzle 24 is movably installed, a water collecting tank 26 is fixedly installed in the purification device 1 , a drainage pipe 12 is fixedly connected to the lower end of the water collecting tank 26 , a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com